According to Michael Porter, a company has a ‘competitive advantage’ when it holds power over its suppliers, competitors and/or customers by virtue of its position in the supply chain. He described 5 forms of power: the power of suppliers; the power of customers; barriers to entry; threat of substitutes and industry rivalry. Porter argued that companies with a competitive advantage generate supra-normal profits.

Porter’s analysis considers companies competing within a free market and it implies the immediate investable future. Strategic advantage, on the other hand, implies a longer-term perspective involving decisions in the short term to secure a longer-term advantage. Strategic advantage may apply to industries of critical national importance where profit is not the main motive, such as energy, healthcare and defence.

While companies can take actions to secure a competitive advantage, it often requires government intervention to secure a strategic advantage due to the timescales and risks involved.

The semiconductor industry is a classic example of strategic advantage vs competitive advantage. Long-term investments by Korea and Taiwan in silicon chip research since the 1980s have developed world-leading capabilities in silicon chip fabrication, especially at leading edge nodes.

In response to Korean and Taiwanese initiatives, other companies have adapted by specialising in other parts of the semiconductor value chain. For example, the UK developed world-leading capabilities in silicon chip design, with companies such as Graphcore designing the world’s most advanced silicon chips, which contain over 50 billion transistors and can only be fabricated by TSMC in Taiwan. ASML (Netherlands) develop extreme ultraviolet lithography machines required by TSMC to fabricate these chips.

Specialising in a particular function encourages innovation, improves productivity and drives down costs. This approach has reduced the cost of a PC from around $5,000 in the 1980s to under $500 today and accelerated the development of new products such as smart phones.

The pace of specialisation accelerated during the 1990s with companies seeking competitive advantage by off-shoring to high-volume, low-cost economies. This reduced production costs at the expense of creating complex, global supply chains.

As modern products become increasingly dependent on semiconductors, supply chain disruptions have a disproportionate impact on national economies, as witnessed during the recent chip shortage; one often cited example is the inability to complete production of a $30k vehicle due to the lack of a $10 chip.

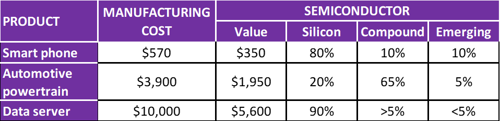

The table below illustrates our dependence on semiconductors:

This table highlights the variety of semiconductors used in a typical product, namely silicon, compound and emerging semiconductors. Typically, silicon chips run the software, while compound semiconductors, comprising two or more elements from the periodic table, provide specialist functions such as facial recognition and power management. A newer category of ‘emerging’ semiconductors provide ancillary functions such as displays.

As economic security requires access to the semiconductors outlined above, several countries have announced initiatives to improve supply chain resilience:

- The US Chips Act provides a $52bn for domestic semiconductor fabrication

- The EU has proposed a €43bn Chips Act

- China’s incentives include a $170bn National Integrated Circuit Fund

- India’s incentives include $10bn for semiconductor fabrication and design

Given the significant sums involved, and the global nature of the semiconductor industry, what strategy should the UK adopt? To answer this question, it’s helpful to consider the Integrated Review, published by Cabinet Office in 2021, which presents a framework for assessing technologies of critical national importance based on UK capabilities within three headings:

OWN: Where the UK has leadership and ownership of new developments, from discovery to large-scale manufacture and commercialisation. This will always involve elements of collaboration and access.

ACCESS: Where the UK will seek to acquire critical science and technology from elsewhere, through options, deals and relationships.

COLLABORATE: Where the UK can provide unique contributions that allow us to collaborate with others to achieve our goals.

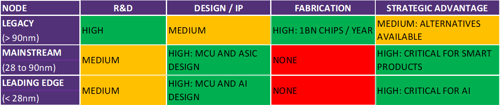

The following heatmaps describe UK capabilities within the main semiconductor groups described above. The first heatmap considers UK capabilities in silicon semiconductors, which are segmented by node size (legacy, mainstream and leading edge).

While this heatmap highlights UK expertise in design, it shows a lack of fabrication capability at strategically important node sizes. Based on the Integrated Review, a strategy of COLLABORATE or ACCESS would be appropriate in this instance.

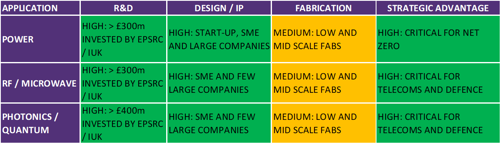

The second heatmap considers UK capabilities in compound semiconductors, which are segmented by application (power, RF/microwave and photonics/quantum).

This heatmap demonstrates UK strengths in R&D and design, resulting from investments by the Engineering and Physical Science Research Council (EPSRC) and Innovate UK (IUK). It also highlights the strategic importance of compound semiconductors for applications such as electric vehicles, telecoms and defence, although it highlights a lack of scale-up capability. Referring to the Integrated Review, the OWN strategy may be more appropriate for this category.

The third heatmap considers UK capabilities in emerging semiconductors, which are segmented by material (OLED, perovskite, thin-film and 2D).

This category is potentially the most complex to assess as emerging semiconductors are relatively new, with new applications being discovered, especially for 2D semiconductors such as graphene. In this case, the heatmap highlights a mixed level of capabilities and a mixed assessment of strategic advantage, reflecting the pace of change. As a result, the appropriate strategy is material dependent.

As a non-profit research and technology organisation, the Compound Semiconductor Applications Catapult is monitoring developments closely. Recent interventions to improve supply chain resilience are likely to reverse the 30-year trend of globalisation, creating more localised supply chains. In the short term, this may increase costs, although building extra capacity will reduce costs in the medium term. In the longer term, we may see a divergence of semiconductor standards based on geopolitical alignment.

Author details: Dr Andy G Sellars, Strategy Director, Compound Semiconductor Applications Catapult