Mixed-signal and analogue design play ubiquitous roles in modern electronics. However, many digital design engineers find the integration of analogue components a daunting task.

So just what are the differences between digital and analogue design? What are the main integration challenges and what have been the recent developments in analogue IP technology that have paved the way for more seamless integration.

Differences between digital and analogue design

Typically, there are digital design experts and then there are analogue design experts. These require separate skill sets as digital design and analogue design are so different.

Digital design operates with discrete signals, characterised by binary digits (0s and 1s), offering a finite range of levels. In contrast, analogue design deals with continuous signals that can assume an infinite array of values, usually represented by varying voltage or current levels.

Digital signal processing techniques dominate the realm of digital design, while analogue design relies on amplifiers, filters, and other analogue circuitry for signal manipulation.

Digital designs inherently exhibit greater resistance to noise and interference, with built-in mechanisms for error correction, but analogue systems are more susceptible to external influences, taking additional measures to mitigate their effects. Moving digital circuits to a new process benefit from the ease of leveraging standard cells and synthesis, facilitating a relatively straightforward transition, whilst analogue circuits often require a more extensive redesign process.

Challenges with design integration

The current shortage of analogue design engineers is forcing many digital designers to face their fears and confront the challenges with traditional mixed-signal and analogue integration.

Merging analogue and digital functions can result in a complex design and ensuring that a design meets all requirements can be difficult. Mixed-signal circuits also demand a focus on physical layout and meticulous component placement for optimal performance and compactness. Managing voltage levels, signal levels, and signal processing between analogue and digital components is crucial to enable seamless functionality.

Mitigating noise and interference in mixed-signal systems requires specialised techniques due to the interplay between sensitive analogue circuits and potentially noisy digital elements.

Maintaining signal integrity is paramount to preserve clean, distortion-free signals, while balancing power consumption and temperature control in mixed-signal systems adds an additional layer of complexity, as digital and analogue components may have different power requirements.

Unlike digital engineers, who often rely on reusable digital IP blocks, analogue and mixed-signal designs may involve bespoke solutions for each project, limiting the potential for design reuse. Testing traditional mixed-signal systems introduces further complications, such as costly specialised test equipment and time-consuming verification techniques that may be unfamiliar to digital engineers and incompatible with their existing tools.

Simulation and sign-off: analogue vs. digital circuits

Simulation and sign-off stages are critical milestones in the design process, providing assurance that the circuit will meet its performance specifications. Here, again, analogue and digital circuits differ.

For analogue circuits, simulation demands a high level of precision to account for the continuous range of possible values. Complex mathematical models are employed to accurately predict circuit behaviour. In addition, corner cases—extreme conditions that circuits may face in real-world scenarios—are meticulously analysed to guarantee performance under varying circumstances.

In contrast, digital circuits benefit from a more straightforward simulation process, as a result of their discrete nature. Logical simulations, often facilitated through tools like Verilog or VHDL, efficiently validate the functionality under a range of scenarios. Sign-off criteria for digital circuits generally revolve around meeting timing constraints and assuring logical correctness.

ATE testing

ATE (Automatic Test Equipment) plays a pivotal role in ensuring the functionality and performance of integrated circuits. Yet, when it comes to testing analogue and digital circuits, there are key differences. Analogue circuits need a more nuanced testing process due to their continuous nature. Specialised instruments are used to accurately measure voltage, current, and other analogue parameters. Additionally, testing analogue circuits often involves specific techniques to assess parameters like distortion, noise, and linearity.

Digital circuits, on the other hand, benefit from standardised testing methodologies enabled by the discrete nature of digital signals. ATE for digital circuits normally means applying a series of logical inputs and analysing the corresponding outputs. This process allows for efficient fault detection, ensuring that the circuit performs as expected under various conditions.

Advances in analogue IP and integration

Every chip incorporates some form of analogue IP, as even digital logic relies on analogue signals for critical functions. Conventional off-the-shelf analogue IP products may require workarounds to fit specific applications, potentially leading to delays in the design process. Fortunately, following new developments in the analogue IP industry, there is now an alternative, more tailored approach.

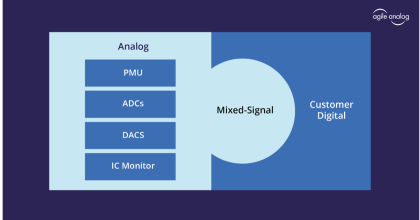

Agile Analog offers innovative analogue IP that is custom-generated and optimised for the specific foundry, process, and node. There is a simple interface with digital logic that enables seamless integration, verification and simulation. The 'digitally wrapped' IP means the experience is far less daunting for digital design engineers. Crucially, this novel technology can significantly reduce the time, effort, and risk in integrating analogue and mixed-signal functionality in an ASIC design.

Open Innovation Platform

Back in September Agile Analog became a member of the TSMC IP Alliance Program, a key component of the TSMC Open Innovation Platform (OIP).

As a result, the complete range of the company’s innovative analogue IP has now become available to TSMC customers, covering data conversion, power management, security, IC monitoring, and always-on-domains.

The TSMC IP Alliance includes major IP companies from across the world and provides the semiconductor industry’s most comprehensive catalogue of silicon-verified and production-proven IP solutions for TSMC technologies.

An open innovation platform it is probably the industry’s most comprehensive and vibrant design ecosystem, which was established to ensure an optimal design experience, easier design reuse and faster integration to help accelerate innovation in design.

Agile Analog has in recent years delivered IPs on a variety of TSMC processes for customers and now, through joining this ecosystem it will be possible to access the PDKs and bring the company’s entire analogue IP portfolio to TSMC process technologies - from high power BCD nodes to standard planar nodes, and the latest advanced process technologies.

Demand for data conversion and power management solutions is extremely high at the moment and it’s expected that the company’s ADC, DAC, and LDO products, in particular, will help to drive semiconductor innovation.

Conclusion

Recent breakthroughs in analogue IP technology have transformed the landscape of mixed-signal and analogue design, making it more accessible for digital design engineers with a background in electronic engineering. With these advances, bringing a new semiconductor design to market can be a much more streamlined and faster process.

Being part of a broader design ecosystem – in the shape of TSMC IP Alliance Program – will also help.

Understanding the differences between analogue and digital design, as well as the unique challenges and potential solutions for integration, is essential for electronics engineers.

As technologies continue to evolve, bridging the gap between analogue and digital will become increasingly vital in shaping the future of electronics.

Author details: Chris Morrison, Director of Product Marketing at Agile Analog