This integrated, large-scale initiative aims to enable Europe’s chip industry to meet its sustainability goals from materials development to final waste treatment.

Coordinated by CEA-Leti, the three-year project brings together 58 partners that span the entire European semiconductor value chain, from large enterprises and SMEs to research institutes, universities, and industry associations.

GENESIS is intended to drive innovative solutions in emission control, eco-friendly materials such as alternatives to PFAS-based ones, waste minimisation, and raw material reuse, all of which will be directly aligned with the European Green Deal and European Chips Act.

“GENESIS is designed to address the complex challenges of building a truly sustainable semiconductor ecosystem,” explained Laurent Pain, Sustainable Electronics Program director at CEA-Leti. “Its structure reflects both the urgency and the opportunity of Europe’s green transition, powered by the complementary expertise and close collaboration of its partners.”

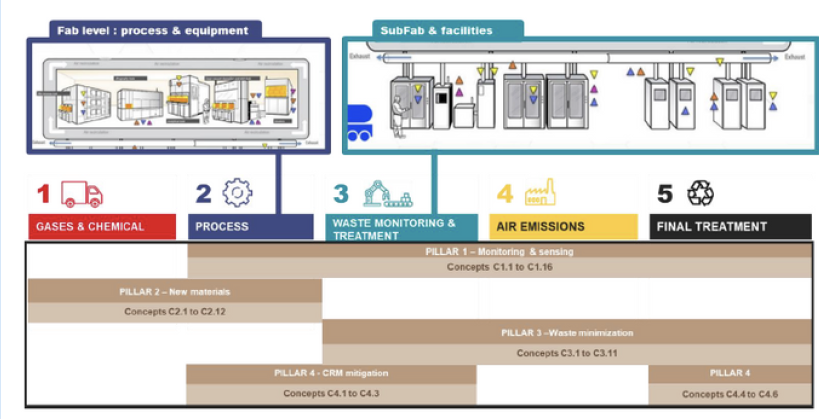

Pain, the manager of the project, said that the team expects to deliver approximately 45 sustainability-driven innovations covering the semiconductor lifecycle, guided by four strategic pillars that form the technological foundation of GENESIS’s vision for a green European semiconductor industry These pillars are:

Pillar 1 – Monitoring & Sensing: Real-time emissions tracking, traceability, and process feedback systems,

Pillar 2 – New Materials: PFAS-free chemistries and low-GWP alternatives for advanced semiconductor processes,

Pillar 3 – Waste Minimisation: Innovations in recycling (solvent, gas, slurries), reuse, and sustainable replacements, and

Pillar 4 – Critical Raw Materials Mitigation: Strategies to reduce dependency on CRM and strengthen resource security.

Complimenting these pillars, the project’s objectives will look to establish an overall framework that includes deploying sensor-integrated abatement systems to reduce PFAS and GHG emissions.

It also aims to position Europe as a leader in green semiconductor innovation by aligning supply-chain practices with environmental regulations.

“The launch of the GENESIS project marks a critical step toward aligning Europe’s semiconductor ambitions with its climate commitments,” said Anton Chichkov, head of programs at Chips Joint Undertaking (Chips JU), a public-private partnership created to bolster Europe's semiconductor industry by fostering collaboration between the EU, member states, and the private sector.

“As chips become the backbone of everything from AI to energy systems, their environmental footprint is rapidly growing,” he added. “GENESIS responds to this urgent challenge by pioneering sustainable alternatives in materials, waste reduction, and resource efficiency. Through this initiative, Europe is not only investing in cleaner technologies - it’s positioning itself as a global leader in green semiconductor manufacturing.”

With a budget of €55 million, the GENESIS project is co-funded through the Chips Joint Undertaking by the European Commission, participating EU member states, and the Swiss State Secretariat for Education, Research and Innovation (SERI).

Above: The Five Critical Stages in Chip-Making Lifecycle Addressed by GENESIS