The much discussed Industry 4.0 takes the automation of the manufacturing process to the next level, with the focus moving from mechanisation and mass production to the decentralisation of the control and regulation of the production process.

This, combined with a move away from the traditional hierarchical communication structures seen in production, has given rise to a new networked model.

“Whilst production automation is currently controlled ‘top-down’, in future we’ll see a much more distributed model,” suggests Mark Ellins, Senior Director, Custom & Enterprise Solution BU, Socionext.

Ellins says that the networking of the various elements that make up the production process will be possible and will help to optimise the entire value-add chain.

“The possibility of each node being able to communicate with others will enable local decision-making and increased efficiency,” says Ellins.

A basic principle associated with Industry 4.0 is the ability it affords those authorised operators to directly access the individual nodes via the Cloud, independent of their physical location.

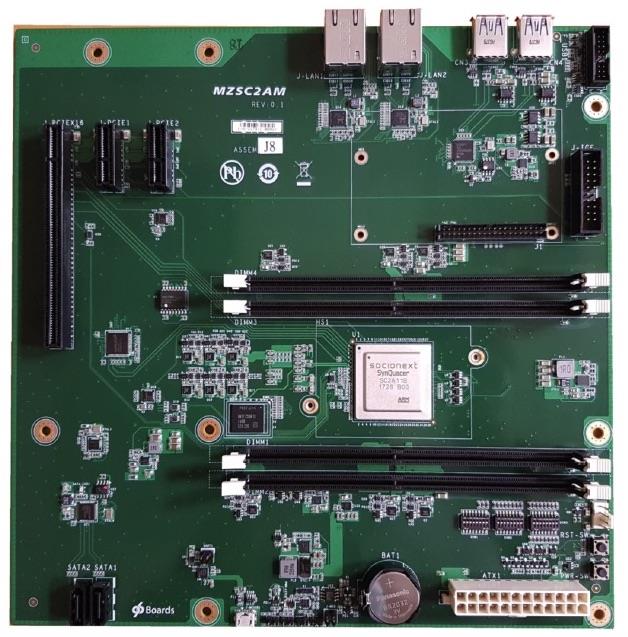

| Figure 1: A MicroATX board with the SynQuacer SC2A11 |

“This will influence the overall production process,” Ellins explains, but that will mean that, “the security of the system will have to be guaranteed. Data Security is an important issue for Industry 4.0. The potential for misuse or external influence is extremely high and security is a key topic.”

Socionext designs, develops and delivers System-on-Chip (SoC) products.

“Our focus is on imaging, networking and computing all of which drive today’s leading-edge applications and, as a business, we have been focused on Industry 4.0 for a long time, working with a long list of customers in this space,” explains Ellins.

“There are a number of key challenges within Industry 4.0 from networking and data handling to supporting new applications such as machine vision, and our focus on computing, networking and imaging matches well with what we are currently seeing in the smart factory space.”

Ellins makes the point that when it comes to the adoption of Industry 4.0, “We’ll have to accept that it constitutes a major structural change in the way in which business will be conducted. While it is being adopted by larger manufacturers, and by companies operating in specialist areas, I believe we’ll see a growing number of SMEs adopting those aspects that are most relevant to their needs.”

According to Ellins, the ability to process vast amounts of data at the Edge is becoming increasingly important.

“While we’re seeing growing demand for computing and networking capabilities on the vision and imaging side, image recognition without human intervention, is becoming more important. We’re working closely with companies who specialise in AI, as a result.”

Challenges abound

Real-time capability is particularly important at the production level. Inputs from sensor values must be processed within defined timescales and this has resulted in new sets of requirements for data transmission and processing.

A further challenge with the implementation of Industry 4.0, according to Ellins, is the large number of communication standards which have been adopted within the production environment.

Crucially, both reliability and functional safety of the individual equipment in use are becoming essential, and in order to reduce servicing requirements for Industry 4.0 components, high Mean Time Between Failure values are now becoming mandatory.

“Functional Safety is of particular importance for production processes where failures could lead to physical risk to the operators,” Ellins suggests.

It is clear, that Industry 4.0 involves a much higher investment in both electronic systems and the supporting IT infrastructure.

The networking of all the individual system components places demands on both hardware and software that require new approaches and ideas.

As Ellins suggests, it has been a subject of focus within Socionext for some time and the company has developed a number of semiconductor solutions which simplify the development and support of Industry 4.0 equipment.

Interestingly, this is particularly relevant when it comes to the company’s Application Specific Integrated Circuits (ASIC) business unit, where a variety of new solutions for applications have been developed.

ASICs are seen as playing a key role in the provision of optimised IC solutions, according to Ellins.

“Industry 4.0, with its special requirements, is an area where ASICs can bring many advantages. These devices are very valuable for a number of reasons, including differentiation and IP protection, which is becoming increasingly important and security. Security of the systems used to support Industry 4.0 is the biggest challenge we face today and we believe that it is better covered by using an ASIC.”

Using ASICs means that customers can develop proprietary logic solutions and have full control over the functionality of the final device.

“Optimised package solutions can be chosen based on the specific requirements of the operating environment and power consumption,” according to Ellins.

Besides the possibility to implement proprietary logic solutions and functionality, the developer can, as part of the ASIC design, take advantage of a large number of per-configured functions such as processors, analogue function such as A/D converters, SRAM or Flash memory.

“We are also able to offer dedicated IP functions which have been optimised for Industry 4.0 applications. One example is our Secure Ethernet Processor IP which enables data communication at rates up to 1Gbps.”

Functional Safety requirements are also covered. For example, loss of clock signals can be monitored by a dedicated on-chip module in order to force the chip into a special fail-safe mode. On the chip reliability side, on-chip sensors can be used to monitor data such as die temperature or power consumption in order to track the device’s aging process and predict failures before they occur.

“ASICs are associated with a higher level of development effort in comparison to discrete solutions, so an ASIC development is probably better suited for higher-volume equipment,” concedes Ellins.

For computing applications, Socionext has developed its Platform SoC family (MB86S7x) of general-purpose ARM-based processors. These devices are intended for complex applications, as in addition to the main processor they also integrate a powerful graphics processor (GPU), as well as a variety of external interface options.

Socionext’s SynQuacer offers a multiprocessor solution with 24 ARM A57 cores.

“This is an extremely powerful processor that has been designed to enable new AI applications in areas such as Machine Vision and Big Data,” Ellins explains.

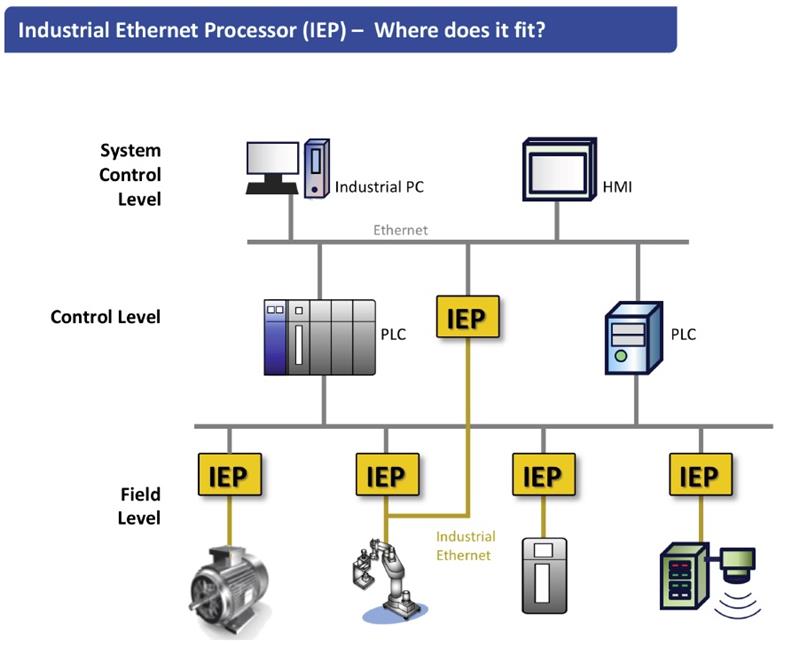

A key requirement of Industry 4.0 is real-time capability across all network nodes, and Socionext has developed an Industrial Ethernet Processor (IEP) that supports two MII/GMII ports for connection to external Ethernet PHYs, allowing the daisy-chaining of network nodes – a common requirement for industrial applications.

The IEP supports several current Industrial Ethernet protocols. It checks received frames and can automatically decide whether these should be stored, processed or forwarded. With its integrated Quality of Service (QoS) engine, the IEP is also able to support the emerging Time-Sensitive Network (TSN) protocol, enabling the transfer of data within guaranteed timeframes as demanded by real-time applications.

Simple control systems can be easily implemented with the IEP. Since the IEP (in addition to its two Ethernet ports) also supports other bus standards, such as I2C and SPI, external devices like displays and sensors can be controlled directly.

More complex solutions can be implemented by connecting the IEP to an external processor and the IEP is also available as an IP block for integration into a larger ASIC solution.

The transition to Industry 4.0 is certainly gathering pace, but is continuing to throw up many design challenges which suppliers will have to work hard to address.

| Figure 2: Socionext has developed an Industrial Ethernet Processor (IEP) that allows for the daisy-chaining of network nodes |