As complex networks are created the convergence of enterprise IT and operational technology (OT) will accelerate as new IoT devices and greater automation technologies are introduced.

While standardised interfaces and state-of-the-art information technology will permit highly flexible, automated ‘plug and produce’ manufacturing as each new device is added to the production process, most will bring with them their own set of proprietary interfaces. As a result, facilitating effective interoperability across the entire manufacturing process will be no easy task.

Earlier this year the consultants, Capgemini, announced the findings of its Smart Factories report for 2017. It reported that manufacturers were expecting their investments in smart factories to drive a 27% increase in manufacturing efficiency, which could be worth an additional $500 billion to the world’s economy over the next five years.

As defined by Capgemini the term “smart factory” looks to cover technologies such as artificial intelligence (AI), advanced robotics, IoT and big data analytics. The smart factory looks set to include collaborative robots, augmented reality and predictive maintenance.

Among those sectors leading in the adoption of these technologies are aerospace, defence, industrial manufacturing and automotive, and in the UK the survey found that 70 percent of manufacturers were looking to use smart factories. The survey found that within the next five years 27% of UK manufacturers said that they were looking to produce their products in smart factories, while 48% said they were looking to establish a network of smart factories.

According to Peter Hannon, UK Managing Director, Harting, the ultimate goal for manufacturers adopting, or looking to adopt, Industry 4.0 or smart factory solutions is to be able to deliver customisable products, increasing quality and reducing manufacturing costs.

“These goals can only be achieved by creating a digital system that is able to gather data and then reports back information on manufacturing processes such as workflow, energy use and faults,” Hannon explains.

“This raw data will be analysed and transformed to provide meaningful insights about the manufacturing process, or a particular piece of machinery, with a view to organising maintenance schedules, implementing automation, managing energy use and contributing to future improvements and savings.”

Peter Hannon, UK Managing Director, Harting

Peter Hannon, UK Managing Director, Harting

Increased visibility at all stages of the production process will enable manufacturers to take a proactive view of activities such as maintenance and production flow, while the inclusion of real-time data means that decisions can be based on the current “live” situation rather than just historical data.

“Industry 4.0 solutions will grant manufacturers much greater flexibility with the use of modular systems that are easily customisable. This means that a manufacturing site will be able to react to market demands and adjust its manufacturing processes and capabilities quickly and cost-effectively,” he contends.

According to Hannon Industry 4.0 comprises of four key elements, “These are: digitalisation, modularisation, miniaturisation and customisation.”

Covering both processes and machinery, digitalisation includes the use of embedded industrial computers and intelligent devices such as sensors to provide data on the machines and processes.

The modularisation of products, factories and processes on the production line is at the heart of the smart factory. Each section can be contained and accessed individually, with modular computers allowing data to be saved, evaluated and then processed at the edge of the machinery.

The miniaturisation, especially where there are high connectivity requirements in areas such as Industrial Ethernet and the Industrial Internet of Things (IIoT), means saving space within the factory infrastructure and the use of next-generation components will enable the faster speeds associated with Industry 4.0.

Finally, customisation across the factory allows the production environment to meet individual users’ requirements and to improve the processes within the factory.

“As well as the benefits customisation offers to manufacturers, it also enables customers to get the most out of the end-product by tailoring it to their specific needs, along with individually customised reports and remote access to production data,” Hannon says.

Modularity

“At the core of the smart factory is the communication between machines, which enables interaction and integration across the whole factory,” explains Gavin Stoppel, Product Manager, Harting.

“Power, signal and data are the three industry ‘lifelines’ on which all manufacturers depend. While links to these specific lifelines can be incorporated directly into the machine, it is also possible to add flexible modular interfaces to transfer data throughout all the levels of the factory.”

Stoppel continues, ”Such devices communicate information and data at all levels, allowing modular production systems to be implemented to provide flexible, cost-effective and innovative production solutions.”

While the Internet provides a platform for direct, interactive, dialogue-centred communication, with network structures replacing the previously used linear design, the cost of deploying a fully integrated system remains a barrier to its widespread adoption.

One solution is retrofitting, according to Stoppel.

“Modular computing forms the basis of a new industrial computer system, MICA (for Modular Industry Computing Architecture), which has been designed to provide existing machinery and systems with intelligence, making it possible to transform existing manufacturing plants into smart factories and bringing to life the potential of integrated industry,” says Stoppel.

“As a result, customers can design their production facilities to be more modular, affordable and less complex. MICA makes it possible to temporarily save, evaluate and process data directly within the machinery and equipment. Based on a modular open platform, it can be customised as required, including the hardware, software and interfaces,” he explains.

MICA functions as a small, robust computing unit between physical devices and a higher-level IT system. It provides a cost-effective solution that allows users to run computing power at all levels as well as communicating with central IT systems and the cloud, offering fast data analysis and decision-making at the field level along with storage and data-collection capability to provide relief for computer centres.

MICA’s open source approach allows users to completely customise the computer: for example, by choosing the programming language and development environment.

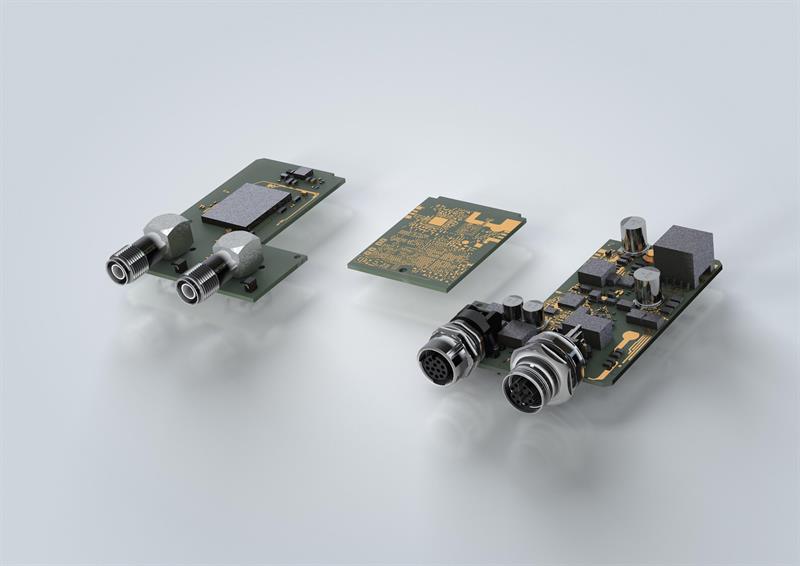

The Harting IIC MICA modular computer

The Harting IIC MICA modular computer

The MICA computer features a powerful 1 GHz ARM processor, 1 Gbyte of RAM and 4 Gbyte of eMMC flash memory (plus an additional 32 Gbyte on a micro-SD card).

The unique identification of plant modules and products is required for production processes to run comprehensively. Real-time production can be viewed via the implementation of RFID (radio frequency identification) systems, along with sensor information for production and maintenance processes.

“This can be used to communicate information about each modular section, and record information for maintenance purposes on writable tags. Identification within the smart factory sees full traceability with continual feedback,” Stoppel explains.

Smart factories have benefited from the concepts surrounding “big data” and properly used, big data will allow machinery and systems to learn and adapt their processes.

Similarly, asset management using a networked environment will enable machines to provide information on their condition and productivity. The resultant data makes it possible to forecast their future operational status and optimise processes which, in turn, assists planning for the requirements of production environment changes and future projects such as new product launches, product modifications or quantity changes.

Whether investing in new systems of looking to retrofit existing systems more manufacturers are beginning to experience the benefits associated with the smart factory.