Measurement techniques

There are several techniques for measuring dielectric properties, using a combination of precise instruments, test fixtures to hold the material under test (MUT), and software that makes it easier to measure complex permittivity and permeability factors and display the results.

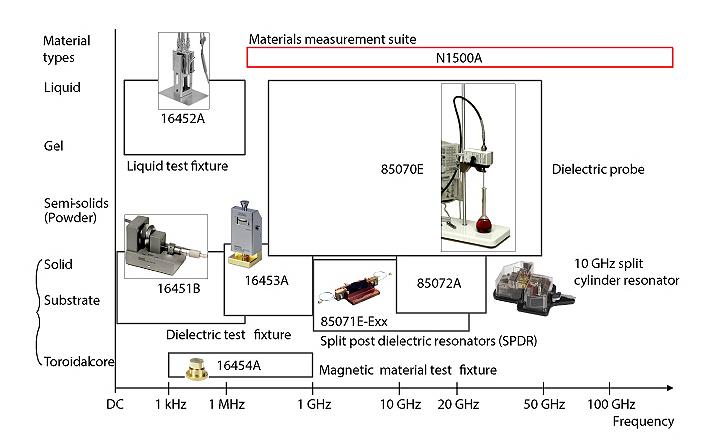

Keysight Technologies, for example, has instruments such as network analysers, impedance analysers and LCR meters that can provide accurate results at applied frequencies of up to 1.5THz. It also offers fixtures that apply the coaxial probe, parallel plate, coaxial/waveguide transmission lines, free-space and resonant-cavity measurement techniques shown in Figure 1.

How do each of these work, and what are their advantages and limitations?

Coaxial probe method

The coaxial probe method is best for liquids and semi-solid (powder) materials. It is simple, convenient, non-destructive and only involves taking a single measurement. A typical measurement system consists of a network analyser or impedance analyser, a coaxial probe and software.

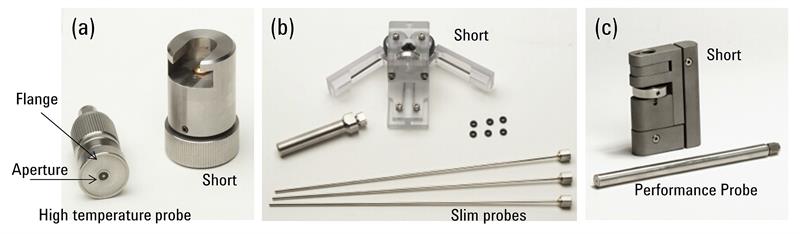

The choice of probe and analyser depends on the measuring frequency, but the overall range is from 10MHz to 50GHz. There are high temperature probes that withstand –40 to 200° C, and these can be made with a large flange so they can measure flat-surfaced solid materials as well as liquids and semi-solids. Slim probes are useful for measuring in fermentation tanks, chemical reaction chambers, and other equipment with small apertures, while high performance probes combine many of these characteristics in a device that can be sterilised in an autoclave – useful for the food, medical, and chemical industries.

Transmission line method

The transmission line method is a broadband technique for machineable solids, which puts the MUT inside an enclosed transmission line. The frequency coverage is limited mainly by the sample holder size.

Free space method

Free space approaches use antennas to focus microwave energy on or through a slab of material. This non-contact method can be applied to materials at high temperatures, and is especially useful at millimetre-wave frequencies.

Resonant cavity method

Resonant cavities are high Q structures that resonate at certain frequencies. A sample of the material affects the centre frequency and Q factor of the cavity, which in turn enables its permittivity to be calculated. For example, Keysight offers the 85072A 10GHz split-cylinder resonator for this purpose, as well as split-post dielectric resonators.

Parallel-plate capacitor method

The parallel-plate capacitor method involves sandwiching a thin sheet of material between two electrodes to form a capacitor. The method works best for accurate, low frequency measurements of thin sheets or liquids.

A typical measurement system using the parallel-plate method consists of an LCR meter or impedance analyser.

Inductance measurement method

This approach derives the permeability of a material by measuring its inductance as if it were a toroidal core. Wire is wrapped around the MUT and its inductance is evaluated with respect to the ends of the wire. Keysight offers the 16454A magnetic-material test fixture, which forms an ideal structure for single-turn inductors, since it doesn’t leak flux when a toroidal core is put in it.

Figure 3, below, maps the various approaches and test fixture types against materials under test and measurement frequencies.

Software

The results of some dielectric measurements can be complex to interpret as permittivity and permeability measurements. Software such as the Keysight N1500A materials measurement suite can make it easier to work with a network analyser, by guiding users through test setup and measurement stages, and then converting the resultant S-parameter data it outputs into your choice of formats. The software supports a variety of measurement methods and mathematical models, to meet most application needs. The software may also be required to model any interaction between the fixture and MUT to allow the extraction of the bulk material properties.

A technique called de-embedding allows a sample to be backed with a dielectric backing on one or both sides. It mathematically removes the effects of the backing, so the electromagnetic properties of just the sample are reported. This is useful when a sample is not stiff or thick enough to stand up by itself, or it cannot be removed from a substrate.

Author profile

Giovanni D’Amore is marketing brand manager at Keysight Technologies.