Because power measurements should be repeatable, this requires instruments that offer accuracy, repeatability and traceability.

Two key instruments for making field power measurements are power sensors and spectrum analysers. The choice of equipment involves a trade-off between accuracy, frequency range, dynamic range, portability, durability and warm-up time.

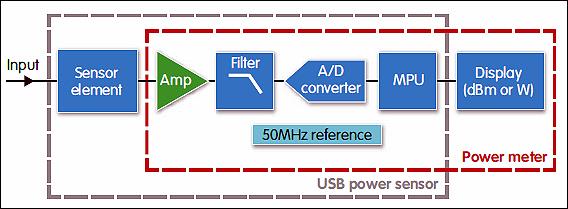

A typical power sensor and meter includes a sensor element, followed by analogue and digital signal processing components (see fig 1). The sensor element converts the incoming RF signal to a DC or low frequency voltage waveform of around 100nV, which is then amplified and filtered. In some configurations, the filter bandwidth can be reduced to improve measurement sensitivity, or increased to improve measurement speed. The analogue signal is then digitised using an A/D converter. A microprocessor handles additional filtering and time averaging of the sampled waveform, as well as interfacing to the keypad and display.

When using a power sensor with a separate power meter, signal processing is handled in the meter (see red box in fig 1). When using a USB-based power sensor, signal processing is handled in the power sensor (black box). Peak power sensors often have extra signal paths to process average and peak measurements separately.

In general, power sensors have the highest measurement accuracy, but require zeroing and user calibration to correct for frequency response, temperature drift and sensor aging. RF power sensing is usually done with thermal or diode-based detectors.

Figure 1: Block diagram of a power sensor and power meter

Thermal power sensors

Thermal sensors monitor a change in one of their electrical properties caused by the energy captured from the RF signal. They respond to the total signal power and report its true average power, regardless of modulation. The sensor element can be thermistor or thermocouple based.

When subjected to an RF input, thermistors warm up and the drop in their resistance can be measured accurately in a bridge circuit. Drawbacks include low RF measurement sensitivity – down to approximately -20dBm – and slow operation. They also need to be connected to a power meter and are sensitive to ambient temperatures.

Meanwhile, the temperature change in a thermocouple caused by RF energy can be measured directly via a voltage change. Thermocouples are more rugged and less sensitive to ambient temperature than thermistors, making them more useful for field measurements. While sensitivity is slightly greater, at approximately -35dBm, they need access to a reference oscillator to calibrate for temperature drift and sensor aging.

Diode-based power sensors

Diode-based sensors have a wider dynamic range, but their non-linear characteristics need compensation in order to achieve accurate average and peak power measurements.

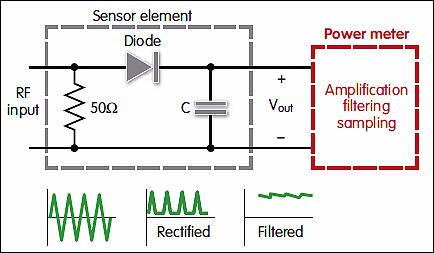

Such sensors rectify and filter the input RF/microwave signal using a diode and capacitor (see fig 2). These devices mainly operate in a region where the detected output voltage is proportional to the square of the input voltage and therefore directly proportional to input power. Here, the relationship between input power and output voltage is linear and, within the region from -70dBm to -20dBm of input signal, the average and peak power of any modulated waveform can be measured accurately. At more than 0dBm, the diode characteristic shifts from a power-to-voltage relationship to a linear voltage-to-voltage relationship, with a transition region from –20dBm to 0dBm.

Diode-based power sensors also need access to a reference oscillator for calibration. For highest accuracy, they should warm up for 30 minutes before use, but are sensitive to ESD and mechanical shock.

Figure 2: Diode rectification and filtering of an RF input

Diode-based power sensors in use

Let’s look at three different uses of a diode-based power sensor.

* Measuring the average power of CW signals

With the right signal processing and compensation techniques, a diode-based sensor can have a dynamic range of more than 90dB. This is often achieved using correction factors held in non-volatile memory to compensate for variations in input power, temperature and frequency.

Measurements in the higher-power transition and linear regions are only accurate for CW signals. Possible applications measurement include testing frequency sources or the output power from amplifiers and any associated gain compression.

* Measuring the average power of modulated signals

The correction factors used in the transition and linear region of a diode-based sensors are not accurate enough to enable the sensor to report the average power of pulsed and digitally modulated waveforms correctly.

One way around this is to attenuate a high-power signal so it is measured in the sensor’s square-law region. However, this will reduce its sensitivity, dynamic range and accuracy.

Another option is to use a sensor with two measurement paths, which keeps the diode operating in its square-law region for all power levels. These wide dynamic range sensors have two measurement paths: one covering -60 to -10dBm; the other, with a built-in attenuator, covering -10 to 20dBm.

* Peak power of modulated signals using diode-based sensors

Measuring the peak power of signals with pulsed and modulated signals requires two levels of signal detection. First, the RF modulated signal is detected using the diode sensor and converted to a wideband signal representing the time-varying envelope of the modulated waveform. The second detection occurs when the wideband signal is sampled at a high rate and processed. Amplitude corrections can then be applied to the samples by adjusting the measured power to match the square-law, transition or linear regions of the diode sensor’s operation.

Tuned receiver power measurements

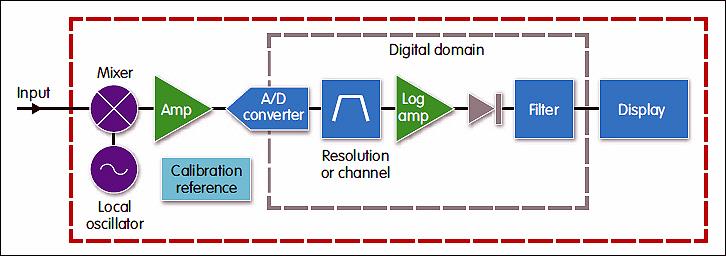

A spectrum analyser can also be used to measure average power. The front end of the circuit shown in fig 3 has a down-conversion block using a mixer and local oscillator. There is also a bandpass filter before the amplitude detector. This architecture converts the RF input signal to a lower frequency, at which it can be filtered and detected more easily.

Figure 3: The architecture of the tuned receiver used in spectrum analysers

Spectrum analysers, such as the FieldFox, use this approach to to display signal power as a function of frequency, by sweeping the local oscillator across a range of frequencies.

This approach also uses an A/D converter to sample the down-converted intermediate frequency for filtering and detection in the digital domain – in this case, in two stages.

In the first, there is a bandpass filter with an adjustable bandwidth which, in a spectrum analyser, is referred to as its channel or resolution bandwidth (RBW).

The next stage is for the signal’s amplitude to be detected and low-pass filtered. In an analyser with a digital IF, the diode detector is actually an algorithm in the instrument’s firmware that simulates an ideal square-law detector.

One advantage of spectrum analysers over power meters is frequency selectivity – the ability to measure the power in a particular RBW. This enables spectrum analysers to measure lower power signals than power meters by selecting a narrow RBW. Where a power meter may be able to measure down to -70dBm, the FieldFox spectrum analyser can measure down to -154dBm/Hz, with a dynamic range greater than 105dB.

It is important to understand the principles of measurement so you know which tools are appropriate and how the results should be interpreted. RF power meters and spectrum analysers have advantages and disadvantages, but understanding them and making the right choice will ensure you get the right levels of accuracy, repeatability and traceability when measuring RF and microwave signal power.

Author profile

Giovanni D’Amore is marketing brand manager with Keysight Technologies.