From logistics to the scaling back of bricks and mortar operations and the rise of the mobile app, the sector is witnessing intense competition and consumers are differentiating less between buying online and in-store; they just want the item they purchase to work, or fit or to be delivered at a specific time that suits them.

Online e-commerce in the UK now accounts for around 15% of total retail sales; a value higher than in almost any other country.

The future of shops is expected to be one in which they are part showroom, part collection point, part space to hold events and provide experiences and services that you wouldn’t get from an online competitor.

According to Helen Dickinson, chief executive, British Retail Consortium: “What people want to buy and how they want to do so is continually changing. The retail industry has to respond. As smartphones have become ubiquitous, retailers have had to offer better value than ever as consumer now have the ability to compare prices instantly while in-store.”

In response to an increasingly tech-savvy generation, the High Street is looking to ‘up its game’ in order to satisfy shoppers and improve the in-store experience.

For consumers, speed and convenience are top priorities and the shift towards online and mobile technology means retailers will need to offer a unified, omni-channel experience. Few retailers, however, are meeting that expectation.

Carl Oxley, pictured right, managing director of Westcoast Retail, a UK distributor and supply chain consultancy, says: “Meeting the demands of increasingly tech-savvy shoppers requires a more innovative approach to distribution and an ability to ensure on-shelf availability.

“Gross margins are being squeezed and overheads for traditional retailers are enormous. To deliver the level of in shop experience demanded by the consumer, and demonstrated by the likes of Apple, is financially impractical for most. Retailers can no longer manipulate prices as was once the case. Consumers have become far more price conscious and have the tools, via the internet, to seek out better deals,” he explains.

“As a result many retailers are engaged in a race to the bottom, cutting costs – which means losing jobs. What we need to see is significant investment in both people and technology and much better management of the supply chain. The mal-distribution of stock is a significant problem and technology has a crucial role to play here,” Oxley suggests. “At present, the supply chain is based on a forecast model – ‘what are consumers going to buy?’. In future, better data management and the use of artificial intelligence (AI) will enable us to better understand individual consumer behaviours.”

Tomorrow, today?

Set up in 2000, Ocado is best known as one of the world’s most successful online-only grocery stores, with revenues of more than £1.1billion.

“We are primarily known as a grocery retailer – ocado.com – but we have other divisions including, Ocado Technology and Ocado Engineering,” explains Alexandru Voica, Ocado Technology’s communications manager. “Those units develop the software and hardware that we use to manage our warehouses and have been responsible for most of the work that has gone into developing the next generation warehouse that we opened last year in Andover.

“We’re neither a traditional retailer nor a pure technology business; instead, we are a fusion between retail, technology and engineering.”

Ocado has been developing its technology over many years and the foundation for its investment and technological development has been its warehouse operations.

The company operates five main warehouses in the UK. Hatfield, Dordon, near Birmingham, and Andover are operational and support the company’s grocery operations. Another warehouse is dedicated to merchandising and the fifth, at Erith in south east London, is under construction.

A dozen smaller facilities, or spokes, are spread out around the country and are where the company unloads trucks.

Sid Shaikh, left, Ocado Engineering’s research and development manager, noted: “We have built systems using technology acquired from outside, but then found that if we wanted to introduce a new process to make the operation more efficient, the technology we needed wasn’t available. The perception of retailers among suppliers hasn’t helped either. Why would we need cutting edge technology?”

Sid Shaikh, left, Ocado Engineering’s research and development manager, noted: “We have built systems using technology acquired from outside, but then found that if we wanted to introduce a new process to make the operation more efficient, the technology we needed wasn’t available. The perception of retailers among suppliers hasn’t helped either. Why would we need cutting edge technology?”

The company’s head office is located at Hatfield, where it also operates a warehouse capable of handling 50,000 products and sorting, for delivery, more than 1.3million separate items each day. Much of the warehouse has been automated by Ocado’s engineers and technical experts.

To handle this kind of volume, the warehouse essentially moves the shopping aisles to and from a human ‘personal shopper’, who then selects product from boxes delivered to them via 25km of conveyor belt. The ‘shopper’ stays in one spot.

Shaikh explains the process. “We receive pallets from our various suppliers which need to be unloaded. They are divided up into totes, which are then transported around the warehouse. Each tote holds one type of product, from which our ‘personal shoppers’ fulfil a specific order. The number of totes will be determined by the type of product an the more totes, the more popular the product.

“We have to be able to handle millions of items and process 150,000 orders each week at Hatfield. Product diversity and volume is exceptional, hence our reliance on technology.”

Connectivity is essential and Ocado has worked hard to streamline its processes though the development and use of AI software systems developed in-house and which manage the system end-to-end.

“We have developed a forecasting algorithm, using things such as what people are ordering, seasonality, special offers and so on, which determines what we should buy,” says Voica. Few of the thousands of products wending their way around the Hatfield warehouse are surplus to requirements.

Artificial intelligence

“AI pervades everything we do here at Hatfield,” Shaikh explains, “whether that’s how we order stock, track data or forecast what we need to buy. That intelligence enables us to deploy staff in the warehouse more efficiently and to manage our fleet of delivery vans more effectively. Van routing software, for example, feeds information back into the system, which prioritises orders at Hatfield. Everything we do is framed by improving levels of efficiency.

“Standard software is not capable of supporting the kind of system we have developed and, alongside the AI software developed in-house, we have designed system diagnostics and self-testing capabilities.”

The Hatfield facility is monitored in real time from a central control room. If the conveyor system stops for any reason, the control room will know, through a real-time computer simulation of all the products and their location along the chain, where and what the problem is and how serious.

“The control system can see tiny little dots representing totes moving around the warehouse,” explains Shaikh. “We can’t afford any significant down time, so we monitor problems in real time and can determine whether problems that arise warrant immediate action or can be postponed. On average, problems are fixed in less than 10 minutes.”

Shaikh notes Ocado’s software means the company can achieve very low substitution rates or missing items. “We have more than 99% customer satisfaction when it comes to order accuracy." (Annual Report and Accounts 2016.)

“The grocery sector is different to the rest of online shopping,” suggests Voica. “Grocery purchasing patterns are regular and established; with other types of online retailing, the patterns are more irregular. It means we need to offer exceptional customer service, because if you don’t, at some point customers will switch to another supplier.”

The possibilities of making mistakes are many, but the end-to-end system developed by Ocado means that individual item can be tracked from the moment it enters the warehouse to when it leaves as part of an order.

Thousands of sensors have been deployed across the conveyor system to ensure that no totes take a wrong turn and are monitored continuously.

“Our aim is to make things smarter. AI means we can learn what should be done in any scenario and that is a key efficiency. My hope is that we reduce software complexity by using AI. Many different things can happen at different levels but, with learning software, it should be easier to deploy systems, make them simpler to install and make modifications easier to manage.”

Robots pick and place

Beyond AI and data management, Ocado is looking at using robots to work alongside its workforce to do picking and placing.

Ocado Technology has created a robotic arm and gripper capable of grasping a variety of products. The project, part of the European Union’s Horizon 2020 programme, has resulted in a ‘gripper’ shaped like a human hand, with the aim being to make it as dextrous and capable as a human one.

“Crucially, we are developing human vision and machine learning systems that will enable the robot to identify various products as well as grip them in a way that won’t damage them and which will integrate well with our existing automated warehouse solutions,” says Voica.

Ocado has also developed a fully automated warehouse at its Andover facility in Hampshire. “Andover, which went live at the end of 2016, demonstrates our Smart Platform,” explains Voica, “and builds on our experiences at Hatfield.”

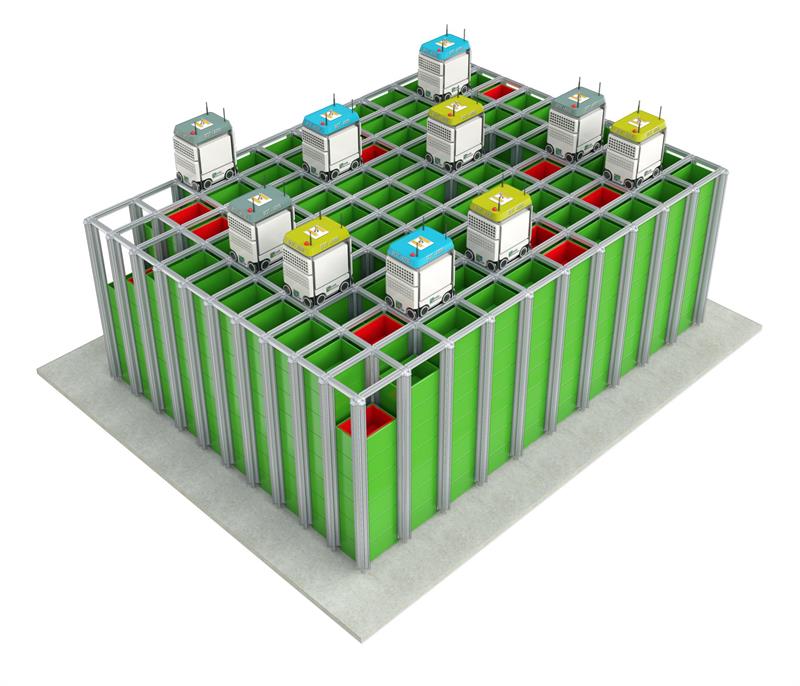

The facility combines densely packed stacks of goods within a grid structure, with products retrieved by what is described as a swarm of autonomous robots. “Hence the name ‘ that we’ve used to describe the facility,” explains Voica.

The facility combines densely packed stacks of goods within a grid structure, with products retrieved by what is described as a swarm of autonomous robots. “Hence the name ‘ that we’ve used to describe the facility,” explains Voica.

Once the crates of groceries have been selected, they are delivered to a human or robot worker, who packs the orders for delivery to customers.

Designed by Ocado, with the help of Newcastle based Tharsus, a developer and manufacturer of electro-mechanical systems, the robots are capable of accelerating and decelerating rapidly, reaching speeds of several metres per second and capable of stopping with millimetre accuracy. They can also pick up significant payloads, move them over long distances and run for several hours on a single battery charge.

Ocado's latest warehouse employs swarms of cooperating robots.

“Because we have developed so much of our own technology – whether software or hardware – we have been able to create our own Smart Platform offering,” explains Shaikh. “Now, we are looking to deliver these solutions to other retailers. We are already working with Morrisons, here in the UK, for example.”

With advances in robotics, artificial intelligence, sensor technology and the Internet of Things the amount of new technology required by the retail space is set to increase substantially over the coming years – the age of the traditional retailer appears to be numbered.