Growth is being driven by a combination of stronger-than-expected growth in the global economy, faster business cycles, greater variety in customer demand and the scaling up of Industry 4.0 concepts.

One of the leading UK developers of ‘collaborative robotics’ is Ocado Technology, which develops the software and systems that power the online grocery retail platforms of ocado.com and Morrisons, the UK’s fourth largest supermarket chain.

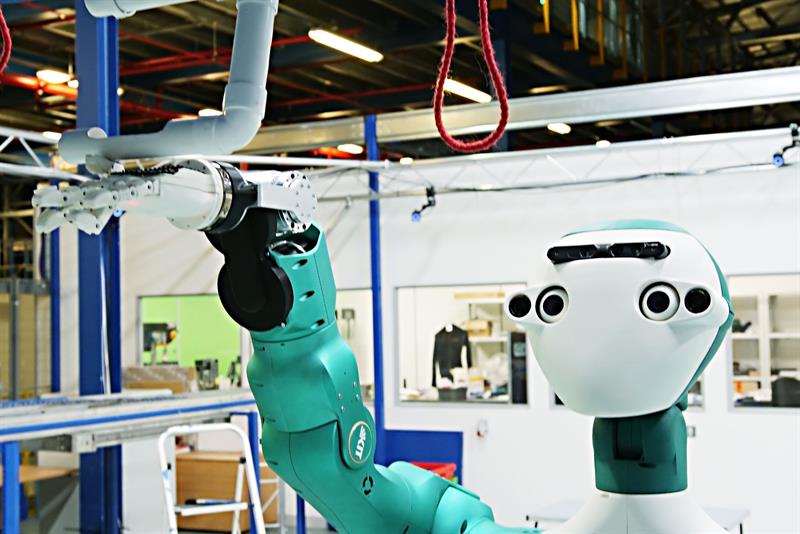

Ocado is involved with a growing number of high-profile research projects, including the SoMa soft manipulation system and the SecondHands technician collaborative robot.

Humanoid robots

While the SoMa project is looking to develop smart and generalised solutions and systems capable of picking out thousands of different grocery items safely and reliably, the SecondHands humanoid robotic project is being developed to help engineers fix mechanical faults and even learn on the job.

“The SecondHands project is intended to assist Ocado’s maintenance technicians and crucially, and most excitingly, anticipate the needs of human operatives,” explains Graham Deacon, who heads Ocado’s robotics research team.

“The robot is intended to be completely autonomous and to be able to perform a variety of tasks from fetching tools to holding objects as well as assisting with cleaning and engineering tasks.”

The robot – described as a ‘second pair’ of hands – will be able to assist technicians and, through observation, augment human capabilities.

“It is intended to complete tasks that require levels of precision and physical strength that are not available to humans,” Deacon says.

“The SecondHands project is a European collaboration between Ocado and four EU universities and it would be fair to say that it is one of the most advanced assistive robot projects in the world,” according to Deacon.

| The SecondHands robot is intended to help technicians in a proactive manner |

European project

Ocado is co-ordinating this European-wide project, funded by the EU to the tune of €7million. The investment forms part of its Horizon2020 initiative to encourage researchers to work more closely with industrial partners.

“While we are co-ordinating and contributing to the research, Ocado will ultimately be the end user and the robots have been designed specifically for our warehouses, or Customer Fulfilment Centres (CFCs).” explains Deacon.

A SecondHands robot prototype was delivered to Ocado’s robotics research lab in late 2017 and, earlier this year, a prototype robot was put through its paces in front of EU officials.

“While there is still plenty of work to do,” concedes Deacon, ”the past few months have provided us with the opportunity to evaluate and then integrate the various research components from the various project partners.”

Those research partners have combined to develop what is described as a real-world solution which has required them to not only take into account the design of a new robotic assistant, but also one that facilitates proactive help, supports a degree of human-robot interaction and the development of advanced perception skills to function in dynamic industrial environments.

Ocado’s research partners include: École Polytechnique Fédérale de Lausanne (EPFL); Karlsruhe Institute of Technology’s (KIT) Interactive Systems Lab (ISL) and its High Performance Humanoid Technologies Lab (H²T); the Sapienza Università di Roma; and University College London (UCL). Various research groups have been focused on computer vision and cognition, human-robot interaction, mechatronics, and perception.

“We want to demonstrate the versatility and productivity that human-robot collaboration can deliver in practice,” explains Deacon.

The research contributions for each of the project partners include:

• EPFL: human-robot physical interaction with bi-manipulation, including action skills learning;

• KIT (H²T): Development of the ARMAR-6 robot, including its entire mechatronics, software operating system and control as well as robot grasping and manipulation skills;

• KIT (ISL): the spoken dialogue management system;

• Sapienza University of Rome: visual scene perception with human action recognition, cognitive decision making, task planning and execution with continuous monitoring; and

• UCL: computer vision techniques for 3D human pose estimation and semantic 3D reconstruction of dynamic scenes.

“Ocado is responsible for the integration of these different functionalities and for the evaluation of the platform,” says Deacon.

While Deacon concedes that while more work needs to be done following the presentation to the EU representatives, it was important that the platform was pulled together.

The SecondHands robot is based on KIT’s next-generation ARMAR robot. “The fact the SecondHands robot has been developed across various sites using different laboratories, tools and facilities, means the project has been complex. But, despite that, everything was ready for January this year.”

| "When something goes wrong ... we want the SecondHands robot to step in and help engineers to carry out repairs quickly and safely." Graham Deacon, Ocado Technology |

As robots evolve from industrial machines performing repetitive tasks in isolated areas of large-scale factories to more complex systems powered by deep neural networks, the SecondHands project has been set the challenging goal of developing, collaborative robots that can interact safely and intelligently with their human counterparts in real-world environments.

“When it comes to maintenance tasks in Ocado’s network of warehouses,” says Deacon, “when something goes wrong with a mechanical component, we want the SecondHands robot to step in and help engineers carry out repairs quickly and safely.

“It should be able to operate in areas deemed too dangerous for humans – examining high-speed conveyors at close quarters, for example, or handling toxic material.”

More importantly, the team expect the robots to track what an engineer is doing, understand the task the engineer is trying to perform and then synthetically understand its own capabilities as a robot to offer assistance proactively.

“SecondHands’ potential for high-level reasoning,” Deacon explains, “is a work of artificial intelligence.”

He explains that software will help the robot construct a vast knowledge base around the tasks it carries out to better understand how they can be applied to problems. “In this sense, the robot will learn on the job,” he concludes.