In a vehicle, when pressing the accelerator, the vehicle speeds up almost instantaneously – there is no noticeable delay between pressing the pedal to acceleration.

To apply this example to the topic discussed here - if the vehicle were a system the surroundings, pressing the accelerator and the output, that is the vehicle’s speed - the system would be implementing what’s known as “real-time control.”

Real-time control is the ability of a closed-loop system to gather data, process that data and update the system within a defined time window. If the system misses that defined window, its stability, precision and efficiency will degrade and the resulting diminished control can be detrimental to system performance; for example, not achieving the necessary speeds or even overheating.

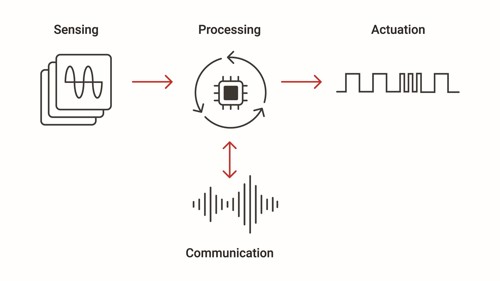

So, what are the functional blocks of a real-time control system and how do they apply to an application?

While not necessarily involved in the control of the system, communications to other system components should also co-exist with the main control loop.

The primary functional blocks involved in real-time control are sensing (gathering data), control (interpreting and using the data), and actuation (updating the system) see Figure 1 below.

Looking at these components in more detail we find that:

- Sensing refers to the measurement of external factors such as voltage, current, motor speed or temperature. These key parameters need accurate and precise measurements in order to give the system reliable data occurring at a specific point in time.

- The central processing unit applies control techniques to the incoming data in order to calculate the next output command. Microcontrollers (MCUs) or controllers such as C2000 real-time MCUs, Sitara Arm-based MCUs, integrated brushless-DC motor drives and DC/DC controllers that contain high processing capabilities can help ensure that the system meets the minimum window of time – usually within microseconds to a few milliseconds.

- Actuation is the application of the calculated output command to the system so as to control the output. Changing the duty cycle of a pulse width modulator (PWM) unit driving a power electronics system is an example of actuation. TI, for example, has developed a number of products that help enhance actuation including analogue drivers, isolated gate drivers and gallium nitride (GaN) field-effect transistors with integrated gate drivers.

- Finally, deterministic high-speed communication interfaces such as Fast Serial Interface or Ethernet achieve timely communication between the system and external devices or internal components.

In robotics, for example, real-time control precisely controls the position and speed of the motor, positioning a robot arm with <100-µm accuracy. Such accuracy is possible through the constant measurement of motor currents and voltages, as well as the motor position.

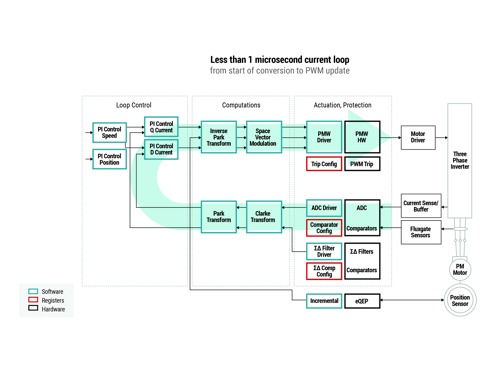

The processing unit compares the measured values with calculated values, as shown in Figure 2. Based on the results, the processing unit adjusts the PWM signal to the motor. And the whole process needs to occur in just a few microseconds to meet the system’s accuracy and timing needs.

Reliable power-supplies

Real-time control is also the basis for efficient and reliable power-supply systems. For example, real-time control helps keep the output power of a charging station stable and regulates current going into a car battery to maintain its life and avoid overheating.

Combining real-time control with an MCU and new technologies such as GaN can increase power density and efficiency, helping minimise power losses in an application.

Consistent increases in the performance of modern motor-drive systems have correspondingly increased the requirements for real-time control. For example, highly fast and precise computer numerical control machines (machines that control a wide range of complex machinery such as grinders and turning mills) can achieve accuracies <5 µm while rotating more than 20,000 times per minute.

Such functionality is only achievable with extremely fast control loops, which means that the time delay between the measurement of the signal and the adjustment of the systems is typically achieved in <1 µs.

Because of the highly time-sensitive computational burden, many designers use a combination of field-programmable gate arrays, fast external analogue-to-digital converters and multiple MCUs.

Some devices, such as TI’s C2000 MCUs and Sitara processors, are able to offer a higher level of analogue integration that enable them to perform a current loop within <1 µs, which is known as a fast current loop. Making use of the fast-current loop in modern control topologies enables designers to develop smaller and higher-performing systems at a lower cost.

It is also possible to reduce cost further by using a fully integrated solution such as the MCF8316 motor driver. These types of devices have pre-programmed brushless DC motor control algorithms that just need fine-tuning, achievable through a simple I2C interface from the MCU to configure integrated electrically erasable programmable read-only memory during the system design phase. They also come with a hardware configuration, enabling system designers to tune the motor without an MCU. The MCF8316 integrates six metal-oxide semiconductor field-effect transistors to deliver the current to the motor, which results in a full real-time motor control solution in a 7-mm-by-5-mm package.

Conclusion

Real-time control plays an important part in a wide range of different applications from grid infrastructure, consumer appliances, to electric and hybrid electric vehicles, and robotics, as described above.

Today here is an increasing need to meet smaller execution windows to enable even faster response times.

Building a real-time system can be a good idea especially if you are looking to run a programme over a certain period of time, or if you need to run it reliably over an extended period as well as where designs are mission-critical or safety-related. These kinds of projects will require a real-time system and the need is clear.

Precise timing and long-term reliability my not be absolute requirements but building a real-time system can also provide added peace of mind and if the system being developed could result in maintenance costs in the event it is interrupted, then the hardware and software costs associated with the development of a real-time system may be well worth the investment.

However, while the benefits derived from a real-time system are clear it does not necessarily make sense for every measurement or control project.

Real-time operating systems are designed to primarily run just one programme at a time, and most real-time systems do not feature a user interface; usually a separate computer must be used to provide graphics or user controls. Also, some projects require hardware determinism where logic is implemented on an ASIC or FPGA.

Despite that, there are thousands of real-time systems in operation today and these types of system will remain a viable solution for projects that need precise timing and high reliability.

Author details: Marlyn Rosales Castaneda - C2000 Applications Engineer at Texas Instruments, Matthias Thoma - Robotics Systems Manager at Texas Instruments