The system structure of automobiles is changing from a distributed architecture to a domain/zone architecture with integrated cockpit systems being adopted that link multiple displays such as meters, In-Vehicle Infotainment (IVI) and head-up displays. And, with these multiple displays, improved image quality and higher resolutions together with compliance to the ISO26262 functional safety standard are critical when it comes to new automotive ADAS and infotainment system development.

So, with the increase in the number of displays inside vehicles and the larger size and resolution of the panels, the vehicle cockpit is no longer a simple interface relaying essential information to the driver.

Today, displays are becoming ever more sophisticated with a whole range of innovative interface designs and can be a key differentiator for OEMs to maximise their brand image.

The different applications in the cockpit have a range of requirements. However, there is one thing in common, which is applicable to most applications: Safety.

Safety is key in today’s vehicles, not only in the cluster display, but also the head-up display and centre stack display. These panels need to realise the specific safety concept, which is allocated to those applications depending upon the individual safety goals.

A cluster display, for example, must meet specific functional safety requirements by integrating dedicated safety mechanisms to realise freeze detection and signature verification.

While warping-on-the-fly is a mandatory requirement in head-up displays, with centre stack displays, with their larger resolutions, they might require display stream compressions.

Amongst all these applications, however, local dimming is becoming a much more common requirement.

Multi-display architectures

So far cluster displays have been the main focus in terms of safety. However, it is no longer the case in most of the multi-display architectures.

Today, the safety concept is being further extended to include heads-up displays because the video content needs to be modified at the display controller end, which is based on the warping matrix and decided according to the optical requirement in each car line. This means, the reference CRC which can be generated at the head unit becomes obsolete. This is also true when the local dimming algorithm is applied, because the RGB pixel value should always be manipulated in order to compensate for the difference of the LED light distribution in each area.

Centre stack displays are also becoming a safety relevant application. This means that a simple CRC check can’t be offered here, because the bit accuracy is no longer kept after stream display compression is applied. Socionext’s latest smart display controller, the SC172x series, has been developed to offer dedicated safety features to fulfil these requirements in cockpit applications.

Warping-on-the fly and Safety

Normally the HMI contents are rendered in a graphic SoC in the head unit. If the reference CRC can also be generated for the safety relevant contents, and sent to the display dynamically, it allows the realisation of a very robust safety concept by an end-to-end contents check.

However, once the video content has been modified at the display side to perform warping-on-the-fly, all video pipeline after warping buffer can’t be covered by this legacy safety mechanism. One solution would be to have another warping engine.

With this design, the second warping engine could then be used either to perform the reverse warping so that the original reference CRC can still be used or to generate the new reference CRC itself. However, this will of course end up with a larger die size and higher cost, due to the duplicated memory and logic.

The biggest challenge is to generate the reference CRC for every frame, according to the defined warp matrix and the video input which changes dynamically.

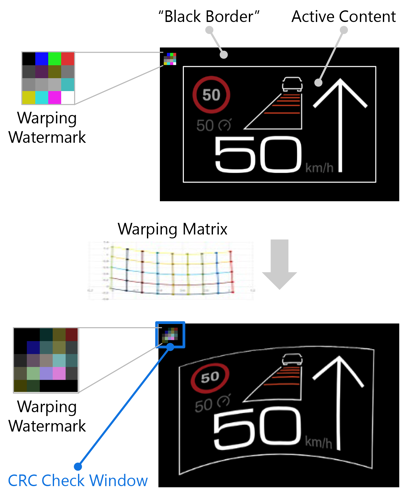

Generating the dynamic reference CRC and comparing it against the actual data is memory intensive. It is possible, however, to have a static CRC as well, by making use of the marginal area which is available in the head-up display, because the active contents are usually smaller than the real resolution.

Since this marginal area has a plain colour (usually black), if the reference CRC is embedded somewhere in this marginal area before warping is applied, this can stay static even after warping. The Smart Display Controller SC1721 series has been developed to offer the safety mechanism to realise this “warping watermark” concept.

Pixel Compensation and Safety

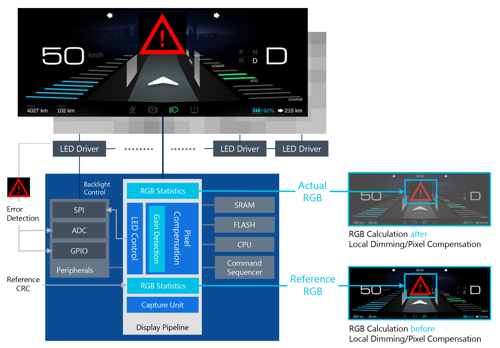

There are two main elements in local dimming; one is the LED control block which calculates the brightness of the LED in each local dimming zone, which is then converted to the PWM value and output to the external LED driver by SPI I/F. Another is the pixel compensation block, which manipulates the RGB pixel value in order to compensate the unintended LED light distribution, so called halo.

If we applied the legacy safety mechanism such as CRC comparison, one possibility is to perform the contents check before the local dimming block, because otherwise the head unit can’t make the reference CRC data when the effect of the pixel compensation is considered. In this case, of course the diagnostic coverage becomes lower.

Unlike the legacy CRC check, it is impossible to define the reference data of the RGB pixel compensation. But if this modification is the intended direction, meaning black becomes a darker black, white becomes a brighter white any malfunction doesn’t necessarily lead to a safety goal violation.

In order to check this ‘direction’, it is possible to have an RGB Statistics Unit before the pixel compensation as a reference, and to compare the result after pixel compensation against it.

In addition to this relative comparison, for which most likely tuning will be required with the actual contents, the Gain Detection Unit can make the concept more robust. It is also possible for this safety mechanism to monitor the internal RGB gain to detect the abnormality, by counting the number of the pixels which is exceeding the normal gain.

In addition to these two blocks (RGB statistics Unit, Gain Detection Unit), other safety mechanisms can also be implemented in all SC172x series to detect the failure in LED brightness.

Depending on the customer’s safety goals, Socionext’s Smart Display controller SC172x series can offer several combinations of these safety mechanisms.

Cockpit Applications and Safety

Socionext’s Smart Display Controller SC172x Series has been developed for the next generation of cockpit applications, particularly where warping-on-the-fly and local dimming pixel compensation are required.

They not only come with the state-of-the-art algorithms built into the company’s graphics pipeline, but they also provide dedicated safety mechanisms which have been developed and integrated under the ISO26262 process to ensure improved levels of safety when it comes to developing the very latest in automotive cockpit designs.

Author details: Nobutaka Yamagishi is Senior Manager Technical Coordination, Automotive Business Unit, Socionext Europe