To truly reach global sustainability, the transition to electric powertrains must go beyond passenger vehicles and needs to impact all vehicles and machinery powered by internal combustion engines (ICE) – including the often-overlooked industrial/off-highway vehicles and machinery.

These vehicles contribute significantly to global greenhouse emissions but electrifying heavy-duty industrial machinery presents a significantly more complex challenge compared to passenger vehicles. This is due to the diversity of equipment and the demanding operating environments that necessitate exceptional durability, reliable power delivery, and minimal downtime.

Essentially, the primary function of a passenger vehicle is to safely and efficiently transport people but when it comes to industrial vehicles they encompass a near endless range of machinery from generators to excavators, all with distinct operational demands and environmental impacts.

Key global industries, like agriculture, construction, and mining, are all reliant on vehicles and ICE powered machinery. The construction industry alone accounts for 26% of the world’s GDP, underlining the importance of these sectors. But the operation of any equipment has considerable consequences, not only because of their energy demands but also due to the locations in which they operate.

Agricultural equipment, such as tractors, harvesters, and generators, are a key part of global food production and their work often spans large rural areas, requiring extended periods without breaks, making them ideal for powerful diesel engines but challenging to accommodate with electric powertrains.

Another significant group of industrial vehicles includes construction machinery. From dusty, congested urban sites to remote rural projects, these vehicles can contribute significantly to local air and noise pollution, particularly in built-up areas like urban centres.

The power needed to continuously lift, move, or dig demands high torque and energy output from diesel ICEs, which creates these high emissions. To provide an example, it is estimated that construction vehicles in London generate 7% of the city’s nitrogen oxide (NOx), 34% of PM10, and 15% of PM2.5 emissions.

Finally, mining and heavy haulage trucks represent some of the most energy-intensive industrial vehicles. These vehicles, designed for material transportation across rugged, isolated landscapes, are integral to global manufacturing, including vehicle battery production. But their size, payload and off-road nature can prove challenging and necessitates immense durability, especially in withstanding vibrations. This results in a significant environmental impact, with over 28,000 large mining trucks currently in operation around the globe contributing a staggering 69 million tons of greenhouse gas emissions.

Key Technical Demands

Replacing ICE with electric powertrains in industrial vehicles is complex and for industrial EVs to be viable, they must meet essential technical demands like durability, increased power capacity, and simple maintenance.

When designing crucial powertrain components for industrial vehicles, such as the high-voltage battery pack, reliability is critical. Industrial vehicles operate in demanding environments, and batteries and electronic components within vehicles must withstand heavy vibration and frequent impacts, all without significant loss of performance. In a commercial environment, vehicle or machinery breakdowns can also lead to significant productivity losses, and in some cases, even pose safety risks. Therefore, these systems need to be built for durability under extreme conditions. For the battery pack, this means proactively monitoring battery health and managing extreme peak loads to prevent performance drops and sudden failures.

Next, high-capacity, long-lasting batteries are essential to meet the energy demands of industrial tasks. While commercial vehicles, like buses, also have larger energy demands than passenger EVs, large construction excavators and mining vehicles have even higher demands. The current largest electric excavators feature a maximum operating weight of around 26 tons and are equipped with batteries boasting a capacity of approximately 300 kWh. However, there are even larger construction excavators that can reach operating weights of 100 tons, and mining models such as Caterpillar’s 6090 FS Hydraulic Shovel have an operating weight of around 1000 tons. These require power far beyond today’s battery technology.

It is also important for engineers to optimise system maintenance and minimise downtime. Industrial vehicles often operate in remote locations where regular maintenance facilities are unavailable. This limited access makes it essential for batteries and electrical components to be durable and easy to service. Batteries must provide accurate monitoring, support long intervals between maintenance checks and minimise unscheduled repairs, ensuring these machines stay in operation as much as possible. For companies relying on industrial machinery, these factors collectively impact the total cost of ownership (TCO) and the overall feasibility of adopting electric power.

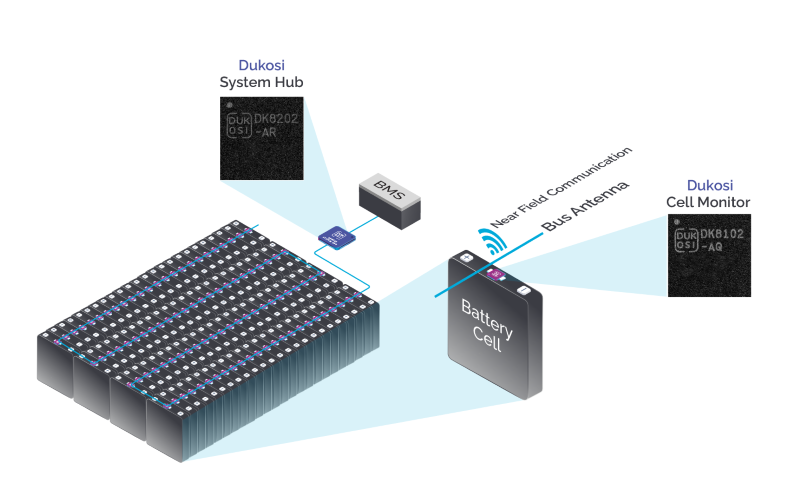

Above: Dukosi’s contactless design simplifies assembly and elevates operation. (Source: Dukosi)

Realising Industrial EVs

If smaller industrial EVs are to succeed, engineers need to deliver the highest levels of battery pack insight, reliability, and performance. By enhancing battery pack monitoring, more proactive maintenance can be facilitated, minimising unexpected downtime that impacts commercial enterprises as well as helping to enhance reliability.

For industrial vehicles traversing rugged construction sites, farm tracks, and mining sites, it is also important to reduce failure points, such as physical connections like the wiring harness, pins, and connectors, to ensure reliability in demanding outdoor settings. Finally, performance and energy density are ultimately key to supporting larger vehicles designs.

The Dukosi Cell Monitoring System (DKCMS) has been designed to meet the needs of industrial applications, where durability and minimal maintenance are essential. Central to DKCMS is the DK8102 Cell Monitor chip, which can be fitted to each cell within a battery.

In commercial industrial applications where a single cell’s failure can disrupt an entire operation, transitioning from module-level monitoring to cell-level monitoring provides more accurate real-time insight, and proactive battery pack maintenance by highlighting weaker or defective cells, helping to improve reliability and extend the overall lifespan of industrial batteries.

Unlike traditional wired battery systems, the DKCMS is a robust and secure contactless system that employs Dukosi’s proprietary C-SynQ protocol and near field communication with a simple bus antenna to connect each DK8102 Cell Monitor to the Dukosi System Hub DK8202, which feeds the BMS host with cell data captured synchronously.

The elimination of wired monitoring in favour of a contactless design streamlines the battery's structure by eliminating the complexities of the wiring harnesses, cutting out the number of connectors, and thereby common failure points compounded in harsh environments. For industrial machinery operators, this shift in architecture produces equipment, including tractors, excavators, and mining trucks, that are more reliable and simpler to service.

Optimising Energy Use

Compared to passenger EVs, industrial machinery and vehicles are often high drain, requiring batteries that can handle aggressive charge and discharge cycles. With a Cell Monitor mounted directly onto each cell, accurate monitoring of key operating parameters such as voltage and temperature allows the battery management system (BMS) to optimise charge and discharge rates, maximising each cell’s performance and ensuring limits are more closely observed.

For vehicles equipped with substantial battery packs, the cumulative effect of even minor improvements in each individual cell’s performance can be considerable, and this more insightful observation can help to enhance the efficiency of industrial machinery. The insights obtained from each cell, which includes multiple parameters measured in a repeatable and systematic manner, is invaluable. This detailed data collection can facilitate cloud-based analytics, enabling performance monitoring across entire fleets and allowing for the optimisation of individual use cases to achieve maximum return on investment.

For instance, mining fleet operators could monitor the State of Health (SoH) of hundreds of thousands of battery cells across their fleet, identifying patterns in cell behaviour that signal degradation well before scheduled servicing. This level of insight can significantly enhance the efficiency of industrial machinery by enabling proactive maintenance and optimised battery usage.

Going Beyond Vehicle Batteries

To ensure true sustainability in industrial machinery, it is important to shift not only the core vehicle offering away from ICEs but also the large mining vehicles and smaller generators that supply power to countless outdoor operations.

While large mining vehicles are beyond the reach of today’s battery packs, many larger mining vehicles can be configured with electric powertrains that can be tethered to an external power supply. For environmentally conscious organisations, renewable solar and wind farms, supported by grid-scale battery energy storage systems (BESSs) hold the potential to power and enhance sustainability.

This same concept can also be applied to replace smaller petrol and diesel generators. Portable solar panels with battery storage affixed to easily movable trailers are already replacing typical generators, allowing for electric tools and industrial machinery to be powered by sustainable energy.

Dukosi’s technology has been designed to support both vehicle batteries and BESS fuelled by renewable energy, where it can deliver the same benefits of reduced battery manufacturing complexity, optimised operation, and predictive maintenance. Implementing contactless chip-on-cell technology on industrial power generators, often subjected to harsh environments, enables increased system efficiency and more proactive monitoring. For businesses focused on TCO, this can lead to the earlier identification of cell issues, fostering preventive maintenance and minimising the risk of unexpected breakdowns.

Conclusion

To achieve global sustainability, electrification must encompass industrial vehicles and machinery that power essential sectors like agriculture, construction, and mining. Electrifying these systems presents unique technical challenges due to high power demands, rugged environments, and the need for durability with simple maintenance.

By utilising advanced technologies engineers can overcome these challenges, reducing emissions while improving operational efficiency, helping us to move closer to a future where sustainable practices are seamlessly integrated into every facet of heavy industry.

Author details: Joel Sylvester, Chief Technology Officer at Dukosi