By removing the need for bulky mechanical components, the technology looks to realise cost and space savings and is able to enhance operational reliability. At its heart is Toshiba’s proprietary compact, high-efficiency silicon photo-multiplier (SiPM).

SiPM are suitable for long-range measurement as they are highly light sensitive. However, the light-receiving cells composed on SiPM require recovery time after being triggered, and in strong ambient light condition they also need a large number of cells, since they must have reserve cells to react to reflected laser light.

Toshiba’s SiPM applies a transistor circuit that reboots the cells to reduce the recovery time. The cells function more efficiently and fewer are needed, securing a smaller SiPM that is able to deliver a higher-resolution SiPM array while maintaining high sensitivity.

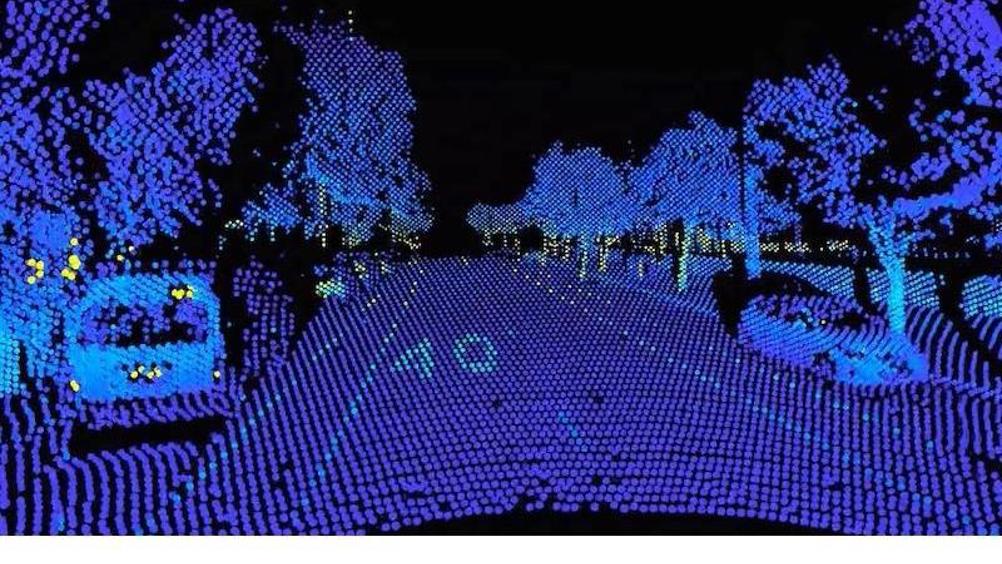

Current LiDAR systems require mechanical components to continuously rotate the laser emitters and their accompanying optical detection devices. Utilising solid-state LiDAR instead secures numerous operational advantages. Field trials with a LiDAR prototype, using commercially available lenses, from wide-angle to telephoto lenses, have demonstrated the system’s effectiveness over a maximum distance of 200m. This effectively quadruples the capabilities of currently available solid-state LiDAR systems while maintaining high resolution.

In addition, Toshiba’s LiDAR system can be built with commercial lenses, which eliminates complex customisation and allows it to be applied in a wide variety of self-driving vehicles. The technology’s inherent compactness allows placement in multiple locations on vehicles that had previously presented a major challenge; and it will also broaden LiDAR applications outside of the automotive sector.

Toshiba enables solid-state LiDAR free from mechanical components

1 min read

Toshiba has announced the introduction of a high-resolution, long-range light-receiving technology for deployment in solid-state LiDAR systems.