The graphene GHS01AT Hall Effect sensor is optimised for use in relatively low field environments and normal ambient temperatures. Bringing the magnetic field measurement resolution towards that of more complex magnetic sensors, yet with the small size and ease of use of a Hall sensor, it is able to address a much broader range of monitoring tasks beyond that of conventional technologies.

The sensors are particularly suited to the battery market where they can be used in battery cell analysis when investigating the validity of different battery cell chemistry derivatives and form factors under development. By using them, it will be possible to get a more detailed and localised (point-to-point) understanding of battery cell behaviour.

Owing to the performance parameters that the GHS01AT delivers, detailed real-time current density (local cell internal resistance) mapping can be carried out - with any variations at different locations in the cell being detected during repeated charge/discharge cycles. If hotspots arise, the local mapping of internal cell resistance in these areas could provide insights into the physical processes occurring in the lead up to their formation.

For example, it might highlight early warning signs which could be monitored in service or scanned for during quality control. It may even provide the information required to help develop battery chemistries and design concepts that altogether safeguard against the risk of potential failure or thermal runaway.

Moreover, the sensors can be used to measure the current flow into and out of cells. The method is an indirect means for measuring real-time magnetic field (current) data, so one of the advantages is that the battery cell itself and the tabs/busbars feeding into the cells are not disrupted during testing.

By utilising a graphene monolayer (just 0.34nm thick), the GHS01AT is not affected by the presence of in-plane stray electromagnetic fields that would severely impact the accuracy of alternative sensing mechanisms. The small footprint also allows for good spatial resolution.

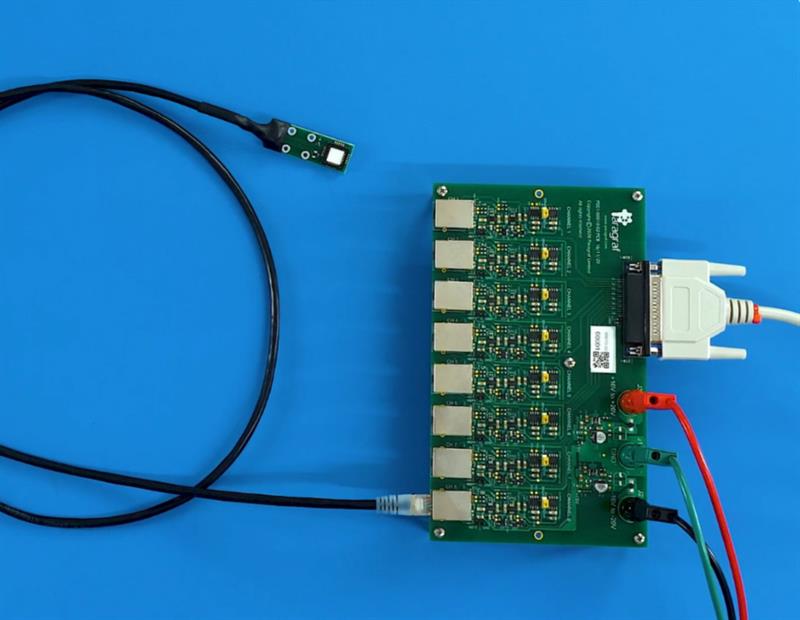

In addition to the sensor, Paragraf is also making available its GHS Array Starter Kit. This compact board enables simultaneous measurements to be taken from up to 8 GHS01AT sensors. Each sensor is attached to a probe with a 1.5m serial interface cable and is accompanied by its own temperature sensor for simultaneous temperature monitoring and temperature correction of the magnetic measurement data. This plug-and-play hardware is simple to integrate into existing data acquisition systems. It will help manufacturers through the initial stages before they look to implement larger-scale test rigs featuring greater numbers of GHS01AT devices.

"Motivated by demands to safely extend EV range and accelerate charging times, battery manufacturers are under intense pressure to develop higher performance products. These need to be smaller and lighter, with heightened power densities and quicker charge responsiveness. To do this, they must have access to superior test data that they can analyse," said Dr Simon Thomas, CEO of Paragraf. "Thanks to our GHS01AT, they now have the technology necessary for such an analysis."

"Battery manufacturers can now compile comprehensive datasets relating to the internal structure of their products from a current density perspective," Dr Thomas continued. "By implementing test rigs incorporating GHS01AT sensors, they will be able to ensure the long-term operation and safety of the battery packs they produce.