Displays are now one of the most important parts of the electronics industry. The reason? Pretty much everything we use nowadays needs a user interface.

If you can't read the display in a variety of lighting conditions or it consumes too much power, then users will not be particularly taken with the product in which it is deployed. LCDs, in particular, consume significant power and suffer from poor viewability.

So a range of companies have been paying particular attention to display technology, pursuing a number of avenues of research. One of these avenues is to apply the principles of MEMS technology to the problem.

Qualcomm – well known for its processors for mobile phones – has set up Qualcomm MEMS Technologies to exploit the opportunities. The technology is being developed in the form of the mirasol display, based on technology developed by Iridigm, which was acquired in 2004 for $170million. Iridigm was itself working on technology developed at MIT.

Mirasol displays are based on interferometric modulation (IMOD) technology and, according to Qualcomm, have paper like readability in almost any ambient condition. The display is also said to consume 'significantly less' power than any other currently available display.

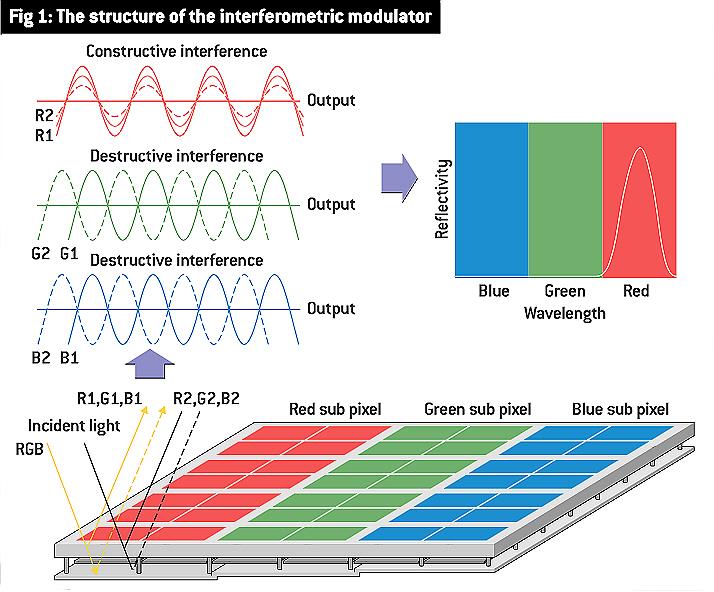

IMOD technology in mirasol displays enables reflective, direct view, flat panel displays to be created. The structure exploits interference, providing a highly efficient reflective display which enables better viewability across a range of ambient conditions.

At the heart of the approach is the MEMS based IMOD, which provides bistability. The basic IMOD element – which can vary from 10 to 100µm per side – comprises two surfaces: a stack of optical thin films and a movable reflective membrane. The air filled gap between the two is an optically resonant MEMS cavity.

The dimension of the optical gap is such that light reflecting within it exhibits constructive and destructive interference. The wavelength at which constructive interference occurs sets the colour of the light reflected by the IMOD element. Varying the size of the air gap allows different colours to be reflected. The blue element has the smallest gap, while the red element has the largest (see figure 1).

When a voltage is applied between the two surfaces, an electrostatic field is created. When this exceeds a given threshold, the field causes the membrane to collapse and the element appears black since there is destructive interference. When the applied voltage is less than the threshold, the membrane returns to its original position and the IMOD element displays a colour.

Since visible light is at the nanometer scale (380 to 780nm), the IMOD membrane only has to move a few hundred nanometers in order to switch between two colours. This means the IMOD element can switch in microseconds and Qualcomm says this will enable video to be displayed with no motion blur.

Mirasol displays are produced using surface micromachining, in which the MEMS device is built on the surface of the underlying substrate. For mirasol displays, requires an array of metal and metal oxide films to be deposited and these are patterned lithographically to produce a microscopic planar structure.

The result, says Qualcomm, is a monolithic electro-optic display which requires fewer process steps to build than the TFT array in a LCD.

Qualcomm also notes that a further manufacturing benefit is that the process has been engineered to take advantage of infrastructure already in place in flat panel display fabs. All materials used for mirasol displays are already used in flat panel display manufacture and substitute materials can also be used.

While it's taken some time to get the mirasol display out of the lab and into the real world, things are now taking off rapidly.

At February's Mobile World Congress, a number of products featuring the display were unveiled.

LG Electronics announced an agreement to begin the development of mirasol enabled handsets. Under the terms of the agreement, Qualcomm and LG will both commit resources to integrate mirasol displays into one or more LG handsets intended for commercial release.

"LG looks for innovations like Qualcomm's mirasol display that can give us a competitive edge and differentiated user experience our customers have come to expect," said LG vice president DooWhan Sang.

Jim Cathey, vp of business development for Qualcomm MEMS Technologies, added: "We look forward to working with LG to begin incorporating colour mirasol displays in LG handsets. This collaboration signifies the commitment we have toward bringing products to market with LG."

Another example was Inventec's V112 Smartphone, which features a 1.1in bichrome mirasol display as a secondary screen. Inventec said the mirasol display allows the V112 to save power by redirecting display content from the primary display. Information to be displayed on the mirasol screen includes time, incoming call, missed call, email and SMS alerts.

Anticipating demand for the technology, Qualcomm has recently opened a fab dedicated to producing mirasol displays. The fab, in Taiwan, is the result of a strategic collaboration with Foxlink, a leading developer and manufacturer of consumer electronics products.

"Emerging technologies, such as mirasol displays, have the power to influence the entire wireless value chain," said Qualcomm's chairman and ceo Paul Jacobs. "As we continue to demand more from our mobile devices, it is clear that the display not only is increasingly influencing the consumers' experience but also is driving the total power efficiency of the device."

Foxlink will apply its manufacturing experience to the day to day operations at plant, while Qualcomm will bring its knowledge of the technology and its process engineering skill.

"The mirasol display holds great promise and we look forward to … taking this technology from the laboratory to manufacturing on a greater scale," said James Lee, president of Foxlink's Microlink Communications Business Units and Systems Business Group. "We are confident that mass production of this technology can be accelerated in terms of volume, scale, colour and time to market."

"The mirasol facility is game changing for Qualcomm MEMS Technologies, as its capabilities move us closer to delivering next generation mirasol displays to the market with increased efficiency and in greater quantities," said Jim Cathey, vice president of business development for Qualcomm MEMS Technologies. "With our technical expertise and Foxlink's background in manufacturing, we are well positioned to enable the commercialisation of mirasol display technology," he concluded.