Thanks to advancements in batteries that can power tech for longer, coupled with highly integrated silicon measurement devices, patients can collect and submit their own vital signs without leaving home or having a health worker visit.

In fact, the emergence of Covid in 2020 and the resultant restrictions limiting face-to-face interaction with health providers also helped to highlight the need for more intelligent, connected, and portable medical solutions.

Wearable sensors and therapeutic devices have the potential to allow patients to leave hospital earlier after surgery, freeing up beds and reducing costs, while enabling surgeons and their teams to continue delivery of high-quality post-operative care. An additional benefit is the collection of regular data points as the patient goes about their normal daily routine, something that may garner insights that would otherwise not come to light.

According to data published by BioSpace, the use of electronic medical products in hospitals is expected to grow at 13% through 2025, and the global market for such devices will reach $169 billion.

Measuring Vital Signs Continuously

The explosion in consumer-grade wearables has had a real impact on many people’s lives. While some questioned the accuracy of wrist-worn sensors for measuring heart rate and other parameters, lives have been saved by their existence. And, while they may not be as accurate as your physician’s professional medical equipment, the fact they monitor continuously has proven invaluable on more than one occasion. One wearer, for example, avoided life-threatening complications thanks to the detection of a high heart rate that, otherwise, would have gone unnoticed for days.

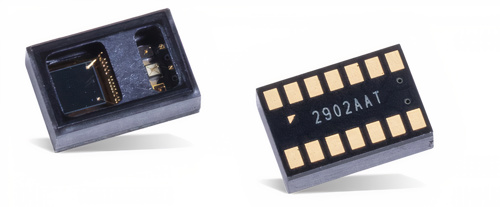

Miniaturised measurement technology such as Maxim Integrated’s MAXM86161 Optical Bio-Sensor is one of a range of devices that make such applications possible. Targeting in-ear measurement applications, it is optimised to detect heart rate (HR), oxygen saturation (SpO2), and heart rate variability (HRV), where beat-to-beat variations are analysed. Integrating with microcontrollers (MCU) via an I2C interface, the device can execute 25 measurements per second while consuming less than 10 uA of current.

The 14-pin Organic Land Grid Array (OLGA) package houses both the sensor receiver and the required green, red, and infrared LEDs. The optical subsystem is constructed of a 19-bit current analogue-to-digital converter (ADC) supported by an advanced ambient light cancellation (ALC) system and a proprietary discrete-time filter. As a result, the measurement solution can operate accurately under high 50 Hz and 60 Hz ambient light conditions. Precision LED drivers are also included with 8-bit control of their dynamic range together with registers for programming pulsing schemes. A 128-sample FIFO ensures that the host MCU can remain in low-power mode for as long as possible before being required to collect a new batch of measurement samples.

A comprehensive prototyping platform is also available.

Adding in an Electrocardiogram

While heart rate can be measured optically, using photoplethysmography (PPG) as we have seen, further information on the heart’s health requires an electrocardiogram (ECG). It was Willem Einthoven who, early in the 20th Century, invented the first practical electrocardiograph. At over 250 kgs and requiring five operators, it couldn’t be considered portable. However, its readings helped Einthoven refine the shape of the instantly recognisable ECG waveform we know today with its P wave, QRS complex, and T wave. While medical professionals typically use a 12-lead ECG monitor, low-cost 3-lead monitors have been shown to deliver measurements of satisfactory technical quality

Measurement devices such as ams’s AS7030B Vital Sign Sensor have been able to make low-cost, continuous monitoring of patients with heart conditions possible. The sensor integrates a PPG and ECG while supporting skin temperature (NTC) and resistance measurements (galvanic skin resistivity) through external sensors. Its 2.7 V to 5.5 V supply voltage range suits operation with a rechargeable battery for portable use, while its small package ensures integration into tiny housings. Connecting to a host MCU via I2C, the AS7030B integrates an LDO, optical and electrical frontend, and an ECG amplifier that satisfies IEC 60601-2-47. PPG measurements are supported by integrated LEDs, while integrated signal processing offloads the host processor and reduces the effect of strong ambient light sources.

ECG signals are very weak, ranging from 0.5 mV to 5.0mV, so it is recommended to keep leads as short as possible or use shielded cables. Care should also be taken with USB connectivity or charging solutions that link the sensor with the grid by using a medically approved isolator (> 3kV) or IEC 60601 certified power supply. An evaluation kit with software is also available.

In the Laboratory

With a preliminary diagnosis made, physicians turn to pharmacologists to analyse samples or develop suitable drugs. Reagents are used in drug discovery and genomic assays but must be dispensed with care. Reagent dispensers can deliver sub-millilitre quantities of liquid but, to do this, they require accurate measurement sensors.

Sensirion has developed a wide range of measurement solutions that build upon their CMOSense intelligent microsensor system that is now in its fourth generation. The SLF3S-0600F Liquid Flow Sensor is one such device, offering measurements of up to 2000 ml/min, and an accuracy of 0.5 µl/min for water (H2O) and 5µl/min for isopropyl alcohol (IPA).

The sensing element uses a micro heating element together with an upstream and downstream temperature sensor. As liquid flows, a temperature difference results that is compensated, amplified, and digitally processed. Millisecond fast response times are attainable with data points passed to a host MCU via I2C. Tubing with an outside diameter of 1/16” to 1/8” together with a matching nut and ferrule are required for attachment to the sensor’s housing.

Measuring Environmental Conditions

Medical equipment development or work in a laboratory, clean room, or hospital often requires environmental monitoring. Recording equipment can be used with climate chambers during hardware testing or to prove that operative or storage conditions meet statutory requirements. The Extech RH520B provides humidity and temperature sensing, storing the measurements in a digital chart recorder.

A paperless design, the internal memory can store up to 49,000 data points, and free software is available to upload measurements to a PC for further analysis.

The sensor can be mounted on the housing of the display or, thanks to its 1m cable, removed and placed within a closed environment. The large graphical LCD offers adjustable vertical/horizontal resolution displaying temperature and relative humidity (RH). Sampling rates of 6 seconds up to 199.9 minutes are supported, while temperature and RH alarms (visual and audible) can be configured if required. The dew point can also be displayed. Power is supplied from the AC adapter included with the chart recorder or, if preferred, three AA batteries offer operation for up to four weeks. Provision for desk or wall mounting is also made.

Thermotherapy solutions can provide cutaneous vasodilation and vasoconstriction through targeted heating and cooling, an approach that can help with pain, blood flow, and inflammation in joints and soft tissue injuries. Some approaches also make use of liquid to deliver a uniform application of the thermotherapy.

Measurement tools, such as Teledyne’s FLIR MR265 Moisture Meter and Thermal Imager, can provide insights on the effectiveness and uniformity of cooling/heating pads during development, and also help determine the location of any leakages.

The MR265 features a multi-spectral dynamic imaging enhancement capability, or MSX, that augments the 19,200 pixels of thermal imaging with data from the integrated 2-megapixel standard camera. Users benefit from more clarity in the images produced on the colour 2.8” display, making it easier to analyse issues back in the office. An integrated LED ensures improved visibility in poorly lit environments, while the integrated laser coupled with Infrared Guided Measurement, or IGM, ensures users are clear which location is being measured. A non-destructive moisture sensor is integrated into the rear of the device, while additional wired sensors can be attached to a dedicated port on the bottom of the unit.

New Medical Analyses and Treatments

While medical equipment has traditionally been bulky, complicated, and expensive, innovations in silicon technology are enabling the creation of simple, battery-powered, and lightweight wearable monitors and therapy delivery solutions.

While not necessarily having the accuracy of professional equipment, these enable continuous monitoring and therapy delivery that can deliver more insights and benefits than a daily or weekly health care visit.

Thanks to highly accurate, next-generation flow sensors, pharmacists are supported in their efforts to develop new drugs and testing methods and as medical engineering teams move their cutting-edge designs into testing, chart recorders and thermal imagers deliver the feedback and monitoring required to improve and optimise their products.

Without a doubt, the field of medical electronics has the potential to deliver some incredible innovations in the coming decade that will make significant improvements to the quality of all our lives.

Author details: Stuart Coding is a technical writer at Mouser Electronics