Since then, it has released 5 in 5 annually and previous predictions included being able to touch via a mobile phone and that computers would be able to hear what matters. Other predictions included personal energy harvesting, biological passwords, air powered batteries and 3D telepresence.

The 2017 5 in 5 list comprises artificial intelligence, hyperimaging, macroscopes, smart sensors and labs on a chip.

According to IBM, labs on a chip have the potential to become nanotechnology health detectives – providing the ability to trace what it calls ‘invisible clues in our bodily fluids’ and letting us know whether we need to see a doctor.

Dr Gustavo Stolovitsky is IBM Research’s programme director for translational systems biology and nanobiotechnology. “Our project is exploring the use of silicon technology to interact with specific bio components in order to help with diagnostics.”

He said the lab on chip concept isn’t new. “It’s been around for a couple of decades, but IBM believes it is differentiating itself in that we’re pushing the envelope to include nanofluidics.”

And the latest push is based on the realisation by biochemists that something called an exosome has the potential to unlock many of the body’s secrets.

Exosomes are nanoscale structures that are present in all bodily fluids. Apparently, biochemists are accumulating evidence that exosomes perform specialised functions and that they have the potential to be used as biomarkers – indicating a person’s state of health – and for prognosis.

Dr Stolovitsky said all cells produce things that transport material – such as DNA and RNA – to the outside for various purposes. “It could be just getting rid of debris,” he said, “or it could be to communicate with other cells. But scientists have recognised they can figure out a cell’s state of health using exosomes.”

Because exosomes carry these biomarkers, IBM’s research is focusing on identifying them, separating them, seeing what they are carrying and then determining whether that information can point towards particular diseases.

As Dr Stolovitsky noted, lab on chip technology has been around for some time and IBM has been involved in its development for many years. A decade ago, researchers at IBM Zurich developed a diagnostic test in which capillary forces were used to analyse serum or blood samples for the presence of disease markers. Their breakthrough was to create capillary forces using a microfluidic chip manufactured using, effectively, CMOS technology – something with which the company had a lot of experience.

“The Zurich team developed chip technology to do diagnostics,” Dr Stolovitsky noted, “and to identify bioelements. While the technology was elegant, it was focused at the microscale. The difference is that our work is focused at the nanoscale.”

Work on identifying exosomes has only really picked up in the last couple of years. “The field is evolving rapidly,” he continued. “We realised in the last two years that the science of exosomes is fascinating and that the particles told stories in ways that no other approach could. Every day, we are hearing about new applications for exosomes.”

His assertion is confirmed by the volume of scientific publications addressing exosomes. “This has grown exponentially in the last couple of years and it’s why now is the time to take advantage of this. But it’s also an opportunity to develop methods of diagnosis that can’t be addressed by today’s technology.”

While scientists are getting a better understanding of the information carried by exosomes, extracting them from bodily fluids is a challenge. “That’s where our technology will come in,” Dr Stolovitsky asserted.

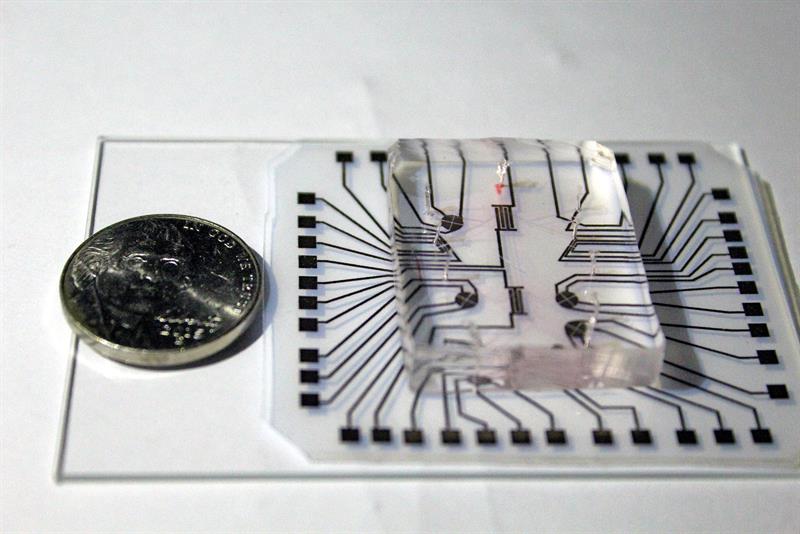

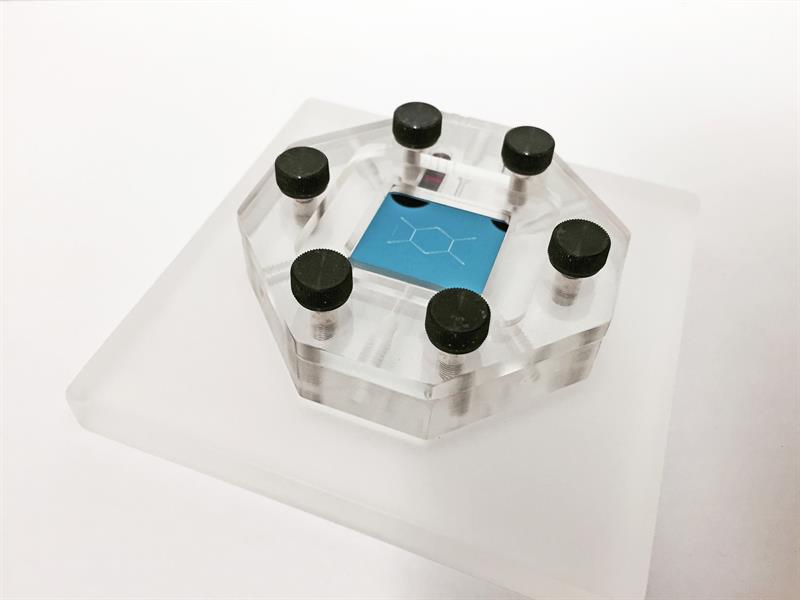

IBM Research's nanoDLD chip in a microfluidic jig

IBM Research's nanoDLD chip in a microfluidic jig

Current practice sees a sample of fluid processed using a differential centrifuge and ultra-filtration. “The problem with this approach,” he said, “is that a lot of exosomes may be lost. Using a centrifuge is difficult, because you have to separate big particles, then small and so on. You also have to spin the centrifuge fast enough to create a centripetal acceleration of 120,000g, which means the exosomes are squeezed.”

IBM thinks silicon technology can do a better job. “We can answer the questions using more adequate technology. But it’s not just the application of old technology,” he continued, “it’s also the development of new technology.”

Dr Stolovitsky pointed out that silicon is a versatile material. “You can use it to do everything from microprocessors to this kind of thing. And IBM has experience of using silicon at this scale; we have all kinds of nanotechnology available at our fingertips. Because we know how to put these things together, the only limit is our imagination.”

Exosomes are extracted from a sample by filtering, although the process is significantly different. “We manage exosomes by channeling them through vias,” Dr Stolovitsky explained, “allowing that materials of interest to be extracted. The design for this process is realised by taking advantage of techniques such as lithography, etching and bonding.” Technically, the approach is called nanoscale deterministic lateral displacement – or nanoDLD. “We start with a silicon wafer, deposit silicon oxide, then etch patterns.” Asked about materials, he said it depends on the application. “In principle, it’s silicon and silicon oxide, but we have also used other materials – for example, metals where connectors are needed. And we recently published a paper outlining how narrow channels can be created using amorphous silicon and sacrificial techniques.”

But the interesting thing about Dr Stolovitsky’s approach is that it is CMOS compatible. “That means we can use a CMOS foundry and our lab on chip design could be very manufacturable.”

So how far has the technology developed to date? “We can already separate exosomes based on their size,” he said. “It’s called the prismatic effect, although there isn’t any light involved – it’s all about particles.”

In theory, when fluid is passed through the channels of a lab on a chip, larger particles should be deflected by 6°, while smaller particles will carry straight on. “You should get a binary separation,” Dr Stolovitsky noted. “In practice, the smaller particles tend to go straighter but, as you get to a critical diameter, the angles change and you get bands of different sized particles.”

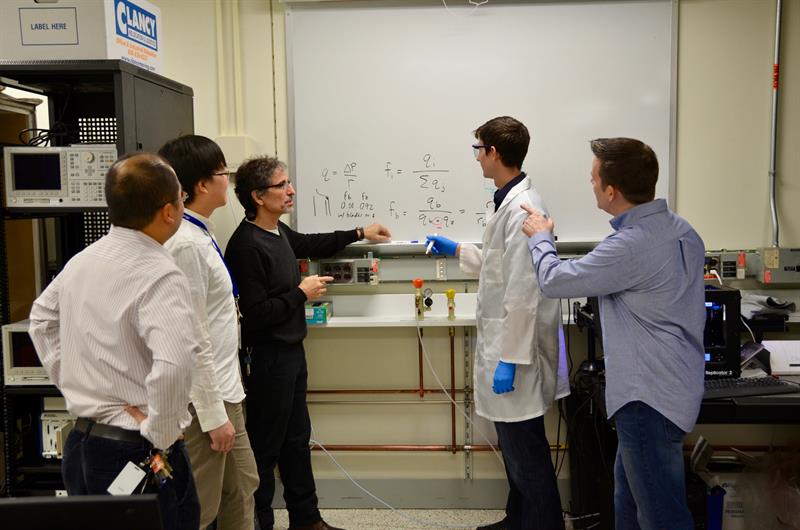

From the left, Huan Hu, Sung Cheol Kim, Gustavo Stolovitzky, Ben Wunsch, and Josh Smith discuss chips for liquid biopsy

From the left, Huan Hu, Sung Cheol Kim, Gustavo Stolovitzky, Ben Wunsch, and Josh Smith discuss chips for liquid biopsy

The approach uses ‘runways’ – channels about 1µm long – in which particles are affected by fluid dynamics. “At the output, bigger particles will be closer to one wall, while smaller particles will be closer to the other wall,” he explained. “No other technology can separate exosomes of a particular size.”

The benefit of using a lab on a chip, rather than a conventional laboratory, is that analysis can be performed as a continuous process; the laboratory is necessarily a batch process.

“If you want to detect exosomes with a particular marker,” he contended, “we believe our technology will enable that. Microscopy can also be used to see if particular particles are present. Researchers can identify and quantify markers for such diseases as prostate cancer and pancreatic cancer.”

So what does IBM’s lab on a chip look like? “The chips are evolving,” Dr Stolovitsky said, “and there are different generations. The thing you put in the microfluidic jig is approximately 1 x 1cm but the effective area – where the capillaries are – measures 1 x 1µm. Within this area are pillars with diameters ranging from 100 to 200nm, with gaps between them ranging from 25 to 200nm.”

The device also needs to be packaged. “But we need to interface it to what’s going on outside. The forward path is a challenge and we need metal connections to interface with other technologies.

“Eventually, we hope to package the lab on a chip with the electronics needed to interface with the outside world; either wirelessly or via connectors. Everything we can do on chip will be on chip – prefiltering, for example – but things like pumps will have to be on the outside.”

Will Dr Stolovitsky and his team meet IBM’s 5 in 5 target? “We will need to define particular areas in order to tailor to them,” he said. “We will also need to make chips reproducible and robust. It will also need us to work with partners to make sure the technology is meeting medical needs; our partners have the medical expertise, so we can join forces in order to get to the target.”

Will they be as widely used as IBM expects? “You won’t see this technology in doctor’s surgeries as a well packaged point of care device with the lab on a chip as its active ingredient in the near future,” he said. “But we are starting to see more potential applications and, once you see the potential, you realise there is an incredible future for the technology. It will make a lot of difference.”

Not surprisingly, he thinks patients will want to see the technology developed sooner, rather than later. “Everyone in this field has dreamed of creating a device like Star Trek’s tricorder and everyone imagines we can do it. I’m certain we’ll see this technology as part of a hand held device.

“In principle, it could be used in the same way as a glucose sensor or pregnancy test is used today. Our vision is being able to meet day to day needs with our technology,” he concluded.

Reusable lab on chip Researchers at the Stanford University School of Medicine have used an inkjet printer to produce a cheap and reusable diagnostic lab on a chip which could be made for as little as 1cent per chip. The two part system comprises a clear silicone microfluidic chamber for housing cells, which sits on top of a reusable electronic strip. The electronic strip can be inkjet printed onto a sheet of polyester using conductive nanoparticle ink. The chip separates cells based on their electrical properties – a process called dielectrophoresis and researchers have show it can capture single cells from a mix, isolate rare cells and count cells based on cell types. |

The benefits of labs on chips, according to IBM Early detection Non-invasive testing Know when we aren’t contagious Complete view of health |