Versatile and innovative data gathering helps to benchmark the workplace, identifying inefficiencies, improving decision-making, operations and employee experiences.

As SpaceIQ puts it, “Facilities managers should see data as more than numbers. Targeted analytics and the information gleaned from them drive better understanding of needed workplace improvements … descriptive analytics can tell you that eight of your 16 hot desks are currently occupied, while predictive analytics tell you this number will be 14 of 16 tomorrow based on past trends. How you use this data depends on your goals.

“From assigning seats, to planning a move or assisting in the collection and analysis of real estate utilization data, a facility management software system makes many aspects of facilities management (FM) easier.”

Research and consultancy Frost & Sullivan goes further, adding that “By learning from historical data and using contemporary technological capabilities, facilities can gain meaningful insights to derive unique opportunities to make creative and efficient decisions that will have a long lasting impact.

Translating sensor data

Increasingly, data needs to be analysed to ensure compliance with health and safety requirements, security and COVID-19 regulations. Flexibility and cost reduction - especially energy savings- provide further examples where facility managers can deliver benefits to the workplace. All this makes for an increasing need to collect data around the building.

The ideal solution would be one without barriers, ensuring exclusive control over the data flow. Additionally, simple implementation would allow facility managers to leverage existing building infrastructure and cloud computing with the lowest connectivity cost, and ideally it would facilitate fast on-boarding, developing proof-of-concept applications that can be scaled rapidly. The key question is finding the right way to get data from the building to the application.

A growing number of solutions are paving the way by enabling collection of data from billions of sensors in buildings, using energy harvesting wireless sensors to collect data in a secure and maintenance-free way. The essential requirements of quick on-boarding, broad applicability and water-tight security are embodied in a new IoT Connector that translates sensor outputs into ready-to-use data for IoT applications and data driven businesses.

Any inputs, anywhere

Wireless sensors play a fundamental part in the world of the Internet of Things (IoT). After all, they are the devices that collect and transmit raw data in IoT systems. All requirements of the IoT are met by wireless (ease of installation and scaling), self-powered (maintenance-free, zero cost of operation) sensors that can be accessed via Internet Protocol (IP).

Energy harvesting wireless sensors that use ambient energy as a power source enable unlimited data capturing where cables or batteries fail to deliver.

These sensors gain their energy from their surroundings – from movement, light and temperature and are used for building automation and especially for IoT applications. One advantage of this technology is that these devices do not require batteries or wires to function. As a result, they can be placed anywhere in the building – exactly where the data needs to be collected. Flexible installation means that building owners and contractors can carry out the work with minimal disruption to tenants.

Data that’s ready to use

IoT applications in smart buildings can only be implemented where the data for analysis and visualisation are not only available, but available in the appropriate format.

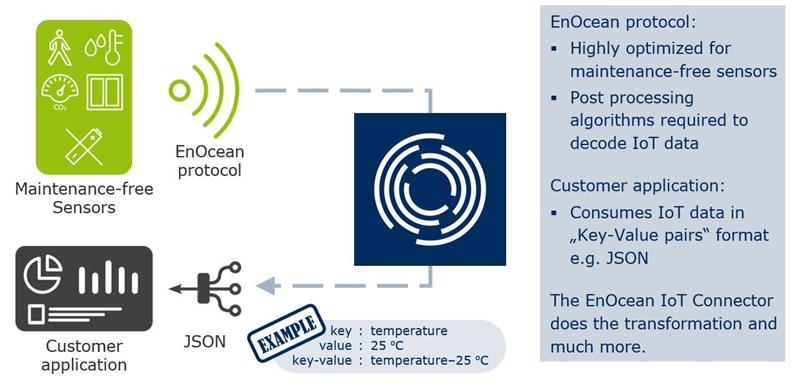

The wireless EnOcean Protocol, which has been standardised by the EnOcean Alliance, is an optimised radio standard for IoT applications, and this delivers all the information and values the customer needs for building their IoT application. The protocol embodied in EnOcean’s technology is designed to run with ultra-low power, and is extremely optimised and compressed to work with energy harvesting technology.

One key feature of the IoT Connector software is that it decodes the IoT data from the EnOcean Protocol and translates it into ready-to-use data in JSON format to be used in the actual application. Algorithms are needed to unravel the data and to make it available for customer applications in the right form. Customer applications consume IoT data in a ‘key-value pairs’ format, such as JSON. A key-value pair consists of related elements: a key, which is a constant that defines the dataset (temperature, humidity or ventilation), for example, and a value, which is a variable that belongs to the dataset (e.g. 20 °C, 80 %, level 1/2/3). Easy adoption by IoT users is enhanced by implementing JSON data that can be exchanged with an MQTT publish/subscribe network broker or Microsoft Azure IoT Hub.

Easy integration

The EnOcean IoT Connector provides a link between maintenance-free IoT data and IoT application, making the integration of EnOcean products much easier. For bidirectional operation, the IoT Connector decodes and encodes the EnOcean Protocol and provides security through end-to-end encryption with AES128 TLS/SSL technology. To provide maintenance-free data, the IoT Connector supervises sensor health information, ensuring that data telegrams are being transmitted in the defined intervals; that radio signal strength is sufficient to send a protocol and that the current and harvested energy stored in the sensor is always sufficient for operation.

Dashboard deployment

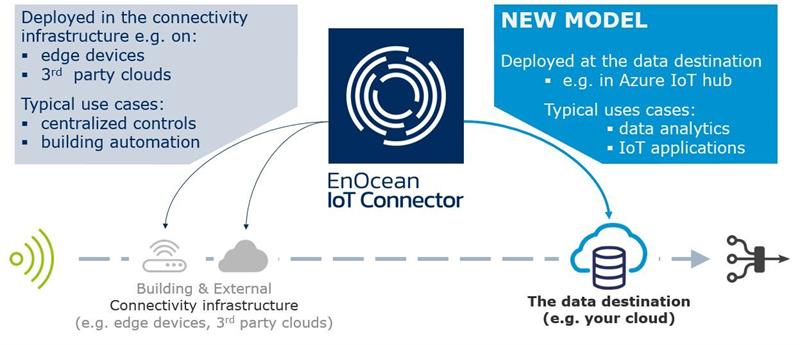

The IoT Connector enables the visualisation and analysis of data collected by maintenance-free sensors in customer-built dashboards and is available as a Docker Container Image. A Docker image is a file consisting of multiple layers that is used to execute applications in a Docker container. The container can run at different locations, using building and external connectivity infrastructure (typical model) or at the final data destination (new model).

In the typical model, the IoT Connector is deployed in an existing connectivity infrastructure: either in edge devices or third-party clouds. Typical use cases are centralised controls such as lighting and building automation. With the new model, the data is processed directly at the final destination like a cloud or server from the customer. For example, this could be Microsoft Azure cloud. Typical use cases are data analytics and IoT applications and the major advantage is that the client has total control over the data flow. With this new model there is no third party or third storage location involved when transferring the data from sensor to cloud. Customers decide what happens with their data, whether visualised, analysed or archived. Here, the IoT Connector is a containerised application and available for deployment at the Azure Marketplace among others, including all updates. The use of cloud computing relieves the load on the local infrastructure and allows new data-heavy applications to be created, stimulating ideas from customers for new applications.

To bring data on board quickly and easily, sensors can be installed and commissioned via direct calls of the Management API, or over a web interface. Alternatively, an Android or iOS app is available for sensors that have a built-in Near Field Communication (NFC) interface or QR code. Sensors are simply scanned during in field installation and included into the IoT Connector.

An easy and cost-effective way to incorporate the EnOcean IoT Connector into IoT applications is by leveraging existing building infrastructures. The infrastructure can easily be upgraded to send EnOcean IoT data, for example with an EnOcean USB stick that is put into a Wi-Fi access point for example from Aruba, a Hewlett Packard Enterprise company.

Also, data from existing EnOcean buildings can directly be forwarded to the IoT Connector in raw format (ESP3 – EnOcean Serial Protocol 3. These

access points support the EnOcean USB stick without need for additional software. The Aruba access points talk directly to the IoT Connector running as part of the infrastructure or the final data destination, so no additional gateways are needed. With this complete scenario, customers have exclusive control over the data flow.

Solutions like these are already helping facility managers to understand, measure and improve their processes and procedures, unlock inefficiencies, improve decision-making and sharpen their operations.

Author details: Marián Hönsch is Product Manager, EnOcean