Many of these companies have little understanding of technology; instead, they have an idea, see value in it and decide to progress with the development of a product. If successful, they face a critical step – how to manufacture it and then scale-up their business.

“Successful innovation shouldn’t require a crystal ball,” says Dr Valerie Lynch, CEO of AND Technical Research (ANDtr), a design and development consultancy experienced in helping companies bring ideas to market. “There is a host of challenges confronting any business looking to bring a product to market. ANDtr has developed a range of skills and techniques that enable us to work with partners at any stage of the project lifecycle, whether that’s at the concept stage or providing assurance through rigorous testing.

“We are not your typical ‘blue sky’ research establishment; rather, we work with manufacturers and distributors alike to identify trends and scout for new technologies,” Dr Lynch explains.

ANDtr provides technical expertise to help businesses achieve project launch readiness and enable them to grow and has developed, what it calls, a ‘navigational approach’ to help companies scale up their operations.

“We’ve developed and used this approach internally,” explains Lynch. “Now, we’re looking to take it to the market, targeting entrepreneurs, CTOs and CEOs. The process involves a combination of strategies, tools and methods and is suitable for any business, whatever its level of technical experience, that wants to bring a saleable product to market.”

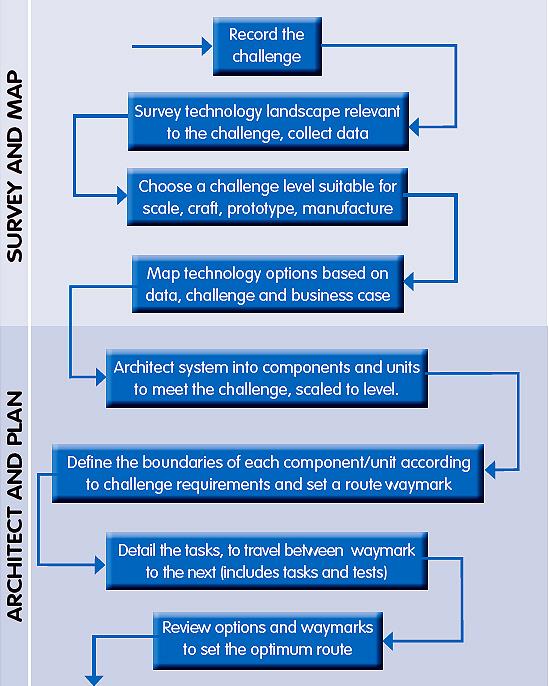

The navigational approach is designed to reduce risk, speed up development and lower development costs.

“We begin by conducting a technology survey, looking at the proposed product concept. We evaluate the product’s feasibility and the required technologies that are needed to support a bullet proof business case. It’s much easier to develop a prototype, than to have a production ready product,” Dr Lynch explains (pictured left).

The approach has evolved in response to the changing nature of those coming to ANDtr with technical or engineering problems.

“For us, it’s been a paradigm shift,” she noted. “Today, we get fewer engineers and more entrepreneurs with what they consider to be a good idea. With platforms such as the Micro:bit or Arduino to hand, anyone can get an idea off the ground and engage with technology.

“Users – whether entrepreneurs, hobbyists or makers – can take an idea, learn how to build a prototype and create a product. The problem then is how do you make that prototype ready for manufacturing?

“In my experience,” she continues, “too many SMEs are crafting products with limited market opportunities and ideas that are, in themselves, not scaleable. There’s certainly a risk that their idea will remain stuck in a product development ‘cul de sac’ and, while there are more sophisticated development boards or professional accelerator platforms available to them, that next step remains a challenge.”

According to Lynch, ANDtr’s in-house expertise means it can build on proven technologies by adding value to propositions brought to it by developers.

“We have multidisciplinary engineers, with experience in electronics, embedded systems, application software, testing and product design,” Dr Lynch explains.

ANDtr’s navigational approach offers four engagement options.

“Each can be contracted separately or can be combined,” Dr Lynch says. “Crucially, we break down the critical steps required to deliver a successful product. Our aim is to help the client develop a saleable product and enable them to scale up their company.”

The first option involves a surveying and mapping service. “We want to de-risk technology development and provide clients with clear pathways forward. This stage answers such questions as ‘what technologies are suitable for the project?’ and ‘how can I productionise my prototype?’. We’ll also look at how much the Bill of Materials is likely to be,” Dr Lynch continues.

It’s at this early stage than many projects fail. “As we’re dealing with fewer engineers, we’re finding that, at this stage, it’s about convincing people what can actually be done – the Laws of Physics need to be understood and recognised. Many claims, when tested, don’t stand up and too many people simply don’t understand the process of taking a product from concept to production – that’s down to a lack of experience and understanding.”

Interestingly, depending on who ANDtr is talking to, the reaction to a ‘fail’ at this stage varies.

“Entrepreneurs or MDs are more accepting. If a product fails, for whatever reason, they want to know why as soon as possible. A project manager, with other targets to meet, might not be so happy.”

The next stage is ‘architect and planning’, where clients are provided with documentation and plans for their project at the design stage. It defines the work to be undertaken, the goals and the details of tasks and skills necessary to complete the tasks and plans of how the work can be tracked and monitored to achieve success.

“This stage extends to overseeing the project, project management and project tracking and,” according to Lynch, “will look to answer questions such as will the project be completed, what are the risks involved in the different options, is the project on track and should a project or project track be halted.”

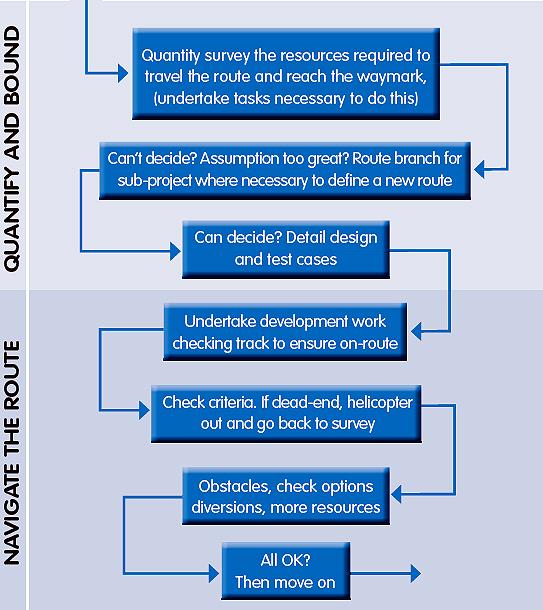

The ‘quantify and bound’ stage delivers test plans and test strategies designed to ensure that the means of reaching project goals are understood and defined.

The work can be applied on different options identified at the architecture stage and allows clients to make informed decisions. The work extends to performing tests and undertaking life-cycle management tasks during and post technology development.

“This stage will determine whether a product is viable and will even consider the risks it could pose to a company’s existing brand. We also assess whether the product is likely to pass compliance testing and what effect its on-going development is having on the Bill of Materials and production costs,” Dr Lynch says.

Stage four, or ‘route navigation’, supplies engineering and technical resource to perform the technology development.

“At this stage, we assign design and development engineers to undertake tasks necessary to complete the project; for example, building test prototypes and commissioning product samples.”

ANDtr can, in conjunction with the client, commission the expertise. Work proceeds in phases set out in work programmes. Each phase is tasked with a testable deliverable and the project’s aims and objectives are reviewed at the beginning and end of each phase to ensure the best route possible through all the options chosen.

Given requirements of the project and the skill sets at ANDtr, there is the possibility to engage the company for any one of the four stages or all of them.

“We can never guarantee success,” Dr Lynch concludes, “but our approach offers companies, whatever their technical experience, a breakdown of the critical steps required to deliver a product to the market and a proven pathway to successful innovation.”