REL’s Skylon space plane, a fully reusable single-stage launch vehicle

Fundamental to its design is the propulsion system that powers it from a horizontal runway launch through to Earth orbit (up to 600km). The Synergetic Air-Breathing Rocket Engine (SABRE) is a type of rocket engine that incorporates elements of a jet engine into its design. The SABRE, and in particular its advanced heat-exchanger technology, provides a breakthrough in propulsion which makes multi-stage launch vehicles a legacy technology. REL’s pioneering engine technology offers improved reliability, a tenfold reduction in cost, and responsive access to space. No longer will space missions take months or even years to plan. REL’s Skylon space plane can take off and land from a runway, which means that a space mission can be conducted as easily as a commercial flight.

Plans for the Skylon plane are still in their infancy but the technology that provides the required thrust to weight ratio – to accelerate the plane to Mach 5.5 inside the atmosphere and to Mach 25 to break out of the atmosphere – is already mature. Whilst conventional rocket engines require vast amounts of liquid oxygen as fuel, the SABRE engine takes advantage of the oxygen in the surrounding atmosphere, which reduces the required oxidiser by over 250tonnes. Once outside of the atmosphere, the rocket phase requires on board oxygen.

During take-off and initial ascent, the SABRE engine runs in jet engine mode so it can use the oxygen in the air. Until REL’s technology, this configuration was not possible. As the air intake speed increases, the air intake temperature also increases. By the time it is travelling at Mach 5.5, the air intake temperature is around 1000⁰C. At this temperature, conventional jet engines cannot operate – materials begin to fail and the air cannot be effectively compressed. REL’s solution to this problem is to super cool the air from 1000⁰C to cryogenic temperatures (-150⁰C) in less than a hundredth of a second with a pre-cooler. Flight weight is the point at which a component’s performance justifies its weight. The pre-cooler required the development of a new generation of heat exchangers that can not only transfer 400MW of heat, but can do it at flight weight, making it 100 times lighter than conventional heat exchangers. This miniaturisation of a heat exchanger can be compared to the miniaturisation of the electronic circuit board to the microchip.

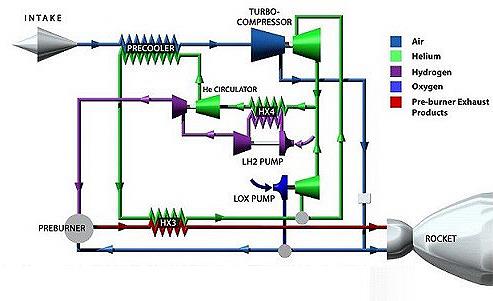

Simplified SABRE cycle

Simplified SABRE cycle

Validation system implementation

The whole test system uses LabVIEW system design software and CompactDAQ measurement hardware.

The modular nature of the platform helped customise the data acquisition system. Using a combination of analogue and digital modules, the data acquisition system had to handle a range of signals, including engine speed, air, and component temperatures varying from -196 to 1000 ⁰C, as well as the flow throughout the system and air pressure from vacuum to 250bar.

For safety reasons, the technicians cannot be in close proximity of the test system during the test but, with flexible DAQmx drivers, acquisition devices could be used over a variety of communication buses with the same application programming interface. For the main pre-cooler diagnostics, a local eight slot cDAQ-9188 chassis communicating via Ethernet was used and a four slot cDAQ-9174 chassis communicating over USB was located within the control room to interface with the plant control system. LabVIEW helped bring together all the different system components under one application. The LabVIEW Data logging and supervisory control module provided integration with a Mitsubishi PLC, which controlled the system and also helped with the development of SCADA UI.

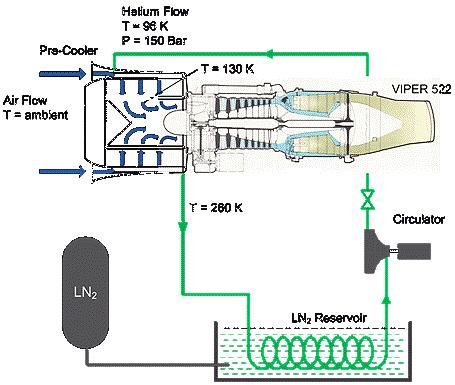

The pre-cooler test circuit

The pre-cooler test circuit

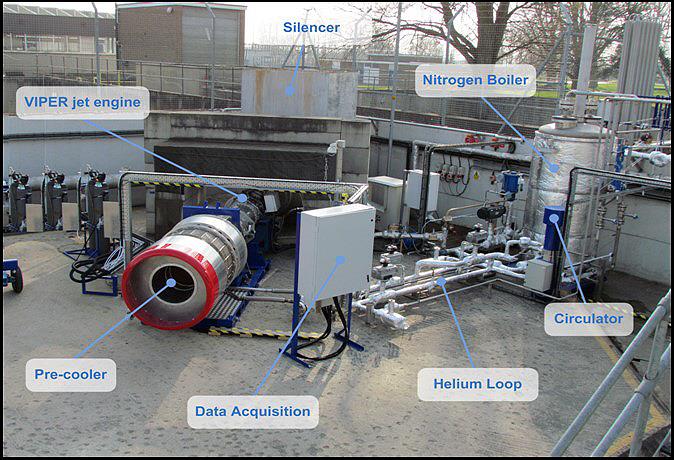

The pre-cooler test rig

Future of the project

The European Space Agency has evaluated the SABRE engines pre-cooler heat exchange on behalf of the United Kingdom Space Agency and has given the test results official validation. Now the pre-cooler has been validated, the testbed can be reconfigured to test other subassemblies before bringing all the subsystems together into a full-size demonstration to commence ground testing of the engine.

With the flexibility of LabVIEW, all the existing components can be reused in the new system and software can be re-written to new requirements. Some of the signals can be reallocated and the system can be enhanced with additional hardware, which saves both on time and the cost of buying a new system.

Skylon, with its SABRE engines, is on its route to 21st century commercially viable access to space.The key enabling technology, the pre-cooler, has been demonstrated, and work is escalating to take the development of system integration testing to the next level. LabVIEW has been an integral development tool for the pre-cooler testing and will be used for further development test systems.

Next steps

Author profile

Michael Hood is head of electrical engineering at Reaction Engines.