Even though a probe may have impressive performance on the data sheet, that may be under ideal conditions. In real world probing, which includes using accessories to attach to the probe tips, performance may be worse than the published data.

An ideal oscilloscope probe would simply provide an exact replica of the signal being probed. But the probe becomes part of the circuit under test (DUT), introducing probe loading. Depending on the different loading effects, the non-ideal loading effects on DUT could impose limitations on the probe’s bandwidth and frequency response flatness in the frequency domain and may cause overshooting, ringing and DC offset problems in the time domain.

One important factor to keep in mind when choosing a high bandwidth probe is that the probe’s loading characteristics may be somewhat different from a conventional probe.

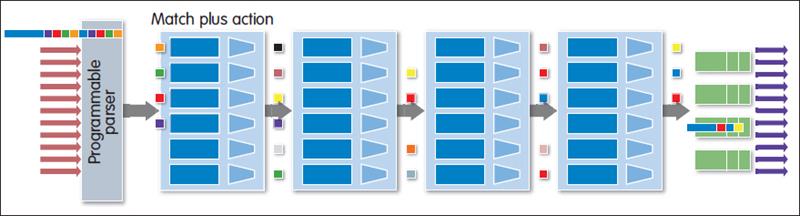

The conventional model of probe impedance looks like this red trace in the input impedance vs frequency chart (Fig 1). The example here is of the Keysight InfiniiMax 1169A 12GHz differential probe. At low frequencies – usually up to about 10MHz – the input impedance can be seen to be 50k?, driven by input R of the probe. Then it intersects the 210fF capacitance of the probe. That is what we call an RC input impedance profile. That is traditional for any oscilloscope probes, including Keysight’s InfiniiMax I or II probes or almost any other probes you may use from day to day.

|

High bandwidth differential probes like InfiniiMax III or III+ have a different input impedance characteristic. They have a 100k? differential impedance at DC and very low frequencies, which intersects with the 50nF capacitance of the probe when you hit mid band impedance (see blue trace). Then, over six decades of frequency, it maintains a 1k? differential input impedance until it finally intersects the 32fF capacitance.

Also shown in the magenta trace is the input impedance plot of another vendor’s high bandwidth probe. Again, it starts at 100k? at DC, then falls due to its 110pF mid capacitance down to a 450? loading, then finally intersects with 65fF capacitance. The crossover frequency of this probe is much higher and it levels out to the midband impedance at approximately 100MHz. This can be described as an RCRC profile. This is very typical of the newer high frequency probe systems such as InfiniiMax III or III+.

Generally, RCRC probes do an excellent job of reproducing waveforms with fast edge speeds, but have effects when trying to measure absolute voltage levels, especially if the source impedance of the target signal is high or if there are long time constants in the signal being probed.

RCRC probes do not provide expected results when probing buses that transition to a ‘high Z’ state, such as when the MIPI D-phy signal transitions from high speed to low power mode. The impedance driving the high impedance bus is typically pulled up or pulled down with a high value resistor and this interacts with the RCRC input impedance, causing very long time constant effects. Therefore, it is generally not recommended to use an RCRC type probe for this type of bus. Instead, an RC type probe with high input impedance across the wide bandwidth range – such as InfiniiMax I, II probe – is more appropriate.

The important point is that users should consider probe loading to ensure that the probe loading is tolerable. Most probe manufacturers provide input loading models, so customers can take stab at understanding the probe loading characteristics before probe selection.

Probe noise

Many users are concerned about the contribution of the probe/scope’s inherent noise to the measurement. There are multiple factors contributing the noise figure of the measurement, but one of the most important is signal to noise ratio (SNR). Typically, a lower attenuation ratio leads to a higher SNR with less noise, but it also yields a lower input resistance, lower dynamic range and lower common mode range. There are some trade offs, but one way to estimate probe noise is to check the attenuation ratio and the probe noise level from the data sheet or manual.

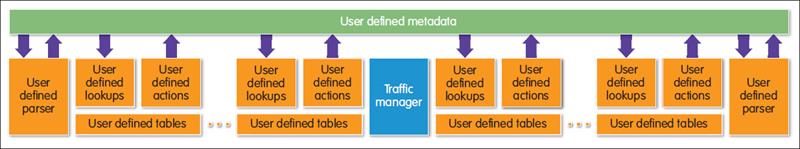

Fig 2 illustrates the situation with respect to SNR. The noise floor of the probe/amplifier system is fixed, so if the signal levels being applied to summing point are not maximised, SNR will degrade. All scopes use an attenuator to vary the vertical scale factor and scope noise happens after this attenuation. When the attenuator is set to any ratio other than 1:1 –the scope’s most sensitive vertical scale range – noise will appear to be larger relative to the signal at the scope’s input connector. So there is an advantage in using the most sensitive vertical range of a scope to avoid magnifying the scope’s noise unnecessarily and degrading the measurement’s SNR. It is also advisable to use a probe with a lower attenuation ratio to achieve improve the SNR.

Once the probe has been selected, the next step is to minimise the ground/signal loop formed by the probe head/tip. Select just enough scope/probe bandwidth, since excessive bandwidth will only contribute to overall noise. You can do this by using the scope’s bandwidth limit control features.

Fig 2: Signal to noise diagram of a scope and probe |

Probe tip may be the weakest link

A measurement system is only as good as its weakest link. The bandwidth of an oscilloscope or a probe is always a banner specification, but there is more to the measurement system than just the oscilloscope and the probe.

In fact, the oscilloscope is often not the weakest link in the measurement system. A measurement system consists of probes, cables, connectors and fixtures. Each element has the potential to cause more loss of bandwidth than the oscilloscope. While cables and connectors typically have very low loss, this is not the case for probes and probe accessories.

If you see a high bandwidth probe that has obviously longer input lead wires at the tip than similar probes, suspect the frequency response variation and degradation. In general, the longer the input wires or leads of a probe tip, the more the bandwidth may be decreased. This can result in an increase in loading as well as a non flat frequency response, leading to more variation in response as span and tip wire environments change. As the bandwidth of the system increased beyond 1GHz, the probe tip effect may play an even more important role in the determining the system performance. Keep the input leads of the probe tip as small as possible, as well as the loop area of connection. And, if you’re using a single-ended probe, keep the low inductance ground connection short and wide.

Author profile:

Jae-yong Chang is oscilloscope probes and accessories product manager with Keysight Technologies.

Fig 1: A plot of input impedance against frequency profile for some common high performance probes

Fig 1: A plot of input impedance against frequency profile for some common high performance probes