The UK has a reputation as being a ‘good place’ to develop and capitalise on innovation supported by a network of world-leading universities and a dynamic innovation ecosystem.

Part of that ecosystem is the ERA Foundation, which looks to bridge the gap between research and commercialisation in engineering. Alongside its commercial activities, the Foundation also sponsors several prizes intended to encourage entrepreneurship and industrial excellence; among these is the Royal Academy of Engineering ERA Foundation Entrepreneurs Award.

This Award was established to encourage and reward creativity and innovation amongst early career engineering researchers working in UK universities. Presented annually to an individual or team which is able to demonstrate considerable entrepreneurial potential, the Award comprises a £10,000 personal recognition award and a £30,000 grant payable to the Awardee’s university for continued development of the innovation by the Awardee.

In addition, Awardees are invited to become Members of the Royal Academy of Engineering’s Enterprise Hub, where they receive a package of bespoke mentoring and training.

This year, the award went to Sorin Popa, the founder of Stent Tek which has developed a device that allows kidney dialysis – and, possibly in the future, even coronary bypasses – to be performed without the need for invasive surgery.

“We have developed a novel catheter based system that provides a better way for patients to receive haemodialysis for kidney failure,” Popa explains. “Without the need for invasive surgery, we are able to provide patients with devices that are not only cheaper but easier to use.”

Since the 1960s, patients with renal failure and who require dialysis have had a Cimino fistula deliberately created in the arm in order to permit easier withdrawal of blood for dialysis.

“This procedure requires plastic tubes to be placed in the arm, under the skin, in order to create a circuit, allowing blood to be taken from the patient, cleansed and then returned. This procedure hasn’t changed in more than 50 years and while it is, and remains, a gold standard the risk of infection is high,” Popa suggests. He points to a failure rate of more than 25% with fistulas failing and not functioning properly.

“Fistulas take several months to mature and there is a risk that the blood vessels will close up as the extra blood flow caused by the fistula leads to blood vessels growing thicker. Fistulas frequently clog up and fail, which can endanger patient lives and require expensive repair operations.

“It’s also requires invasive surgery so the surgical creation of the fistula can, itself, traumatise the blood vessels leading to delays in the maturation of the vein delaying its use.”

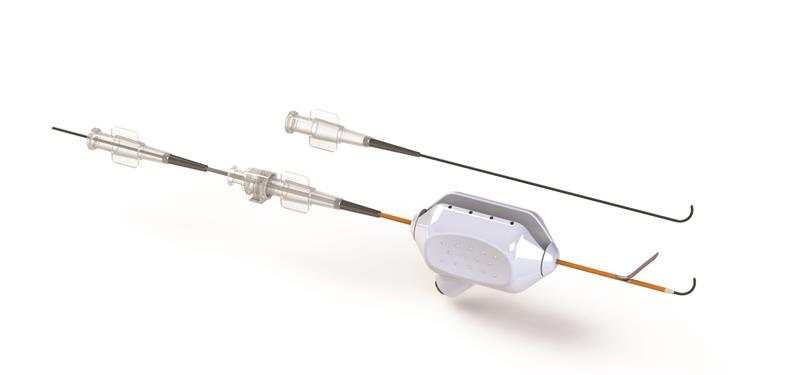

Stent graft

In order to address these issues, Stent Tek has developed a medical device that, through only two needle-sized punctures, enables a small covered tube known as a ‘stent graft’ to connect blood vessels in almost any part of the arm, enabling patients to receive lifelong kidney dialysis but, crucially, without requiring surgery.

The device deploys an innovative electronic alignment technology that allows the clinician to accurately guide the needle.

“At present most procedures use x-ray imaging to navigate and rotationally align catheters, which can be difficult. We generate an electric field to guide the second needle which enables an accurate alignment of the needle and ensures that it is pointing in the right direction.”

The procedure is handled by a handheld device with no need for standalone imaging equipment, Popa explains, and x-ray usage is also expected to be significantly reduced.

“The current procedure is difficult to perform well and there is a large variance in success rates and the quality of fistulas. Our approach will help to standardise the procedure and reduce rates of failure.”

Popa not only receives funding but now, as a member of the Royal Academy of Engineering (RAE), gains access to the Enterprise Hub which provides him with a mentor from the Academy’s Fellowship, training in how to run a successful business, and access to an exclusive network.

Commenting, Ana Avaliani, the RAE’s Head of Enterprise, said: “The Enterprise Hub is focused on identifying and supporting cutting-edge technology innovations from UK universities with real commercial potential, and Sorin’s technology is a perfect example of this.”

The market is huge with more than 2.5million patients requiring dialysis each year.

“In the US alone, the healthcare system is spending more than $4billion a year to treat failed fistulas and early projections are that, in the UK, this procedure could save the NHS more than $45m a year,” Popa believes.

Stent Tek, which has already won a £166,000 ‘Smart Award’ from Innovate UK and a £1m grant to develop the technology in partnership with Imperial College London, is aiming to bring the technology to market by 2018.

Popa co-founded the company after graduating from Imperial where he had studied medical device creation and entrepreneurship.

“Early stage development isn’t easy and I was only able to fund the business through doing some consultancy on the side. When you look for funding, it is extremely competitive and difficult to get. We did manage to get support from the likes of Innovate UK and with some funding in place we were then able to attract private capital.”

The Enterprise Hub is proving invaluable, according to Popa.

“It’s really helped, I’ve learned about business development, how to negotiate, model my business and crucially, gain a better understanding of the legal side of things.”

Wearable medical fabrics

This year’s other ERA Foundation Finalists joining the Enterprise Hub include: James Carroll, University of Strathclyde, who designed a X Rotor Wind Turbine; and Dr Kai Yang, from the Zepler Institute at the University of Southampton, who has developed a fabric electrode for wearable medical and healthcare applications.

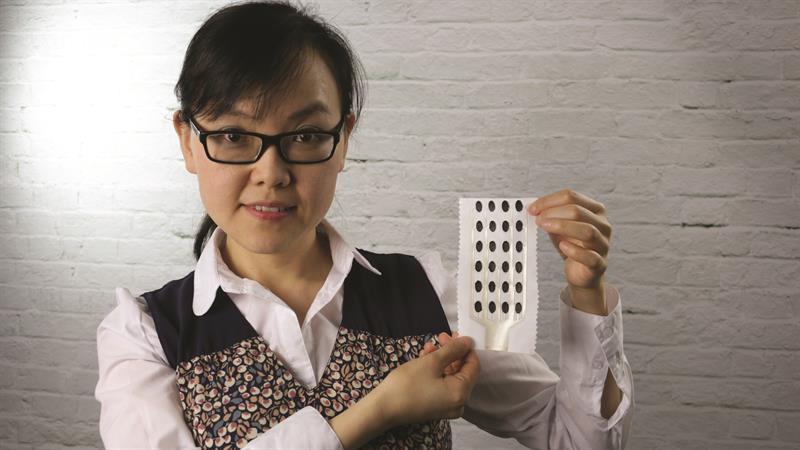

Dr Yang, a graduate of the Beijing Institute of Fashion Technology, who obtained her PhD in 2009 from the University of Leeds, has developed a fabric based electrode for wearable medical and healthcare devices. The electrode can be applied on the skin directly without using any gel and has been created in such a way that it can be used on everyday fabrics to form a range of clothing items, such as an arm band or sleeve, for various applications.

“Our main challenge was developing something that was comfortable and easy to use,” Dr Yang says. “It needed to be something that could be integrated easily into a piece of clothing, which people would not notice, and which could be worn anytime and wherever they went. Durability and washability were crucial.”

The fabric based electrode is not a single big device; rather, it’s an array of 24 separate electrodes, accompanied by advanced control and sensor technologies.

“It means that we can tailor treatments and treat the affected area directly,” Dr Yang explains. “The system compares a targeted task with the individual’s performance using sensors and a computer program. The device is powered and controlled wirelessly and we have created a learning control system capable of working and developing with the patient as they recover.”

The fabric electrode is a ‘platform technology’, according to Dr Yang and can be used in Functional Electrical Stimulation (FES) for stroke rehabilitation, transcutaneous electrical nerve stimulation for pain relief, and health monitoring.

Dr Yang secured £1.1m in research funding from the Medical Research Council to develop this wearable FES training system.

A member of the Enterprise Hub, Dr Yang enthuses about her mentor and the support the Hub has been giving to her.

“My mentor is simply brilliant. Their advice has been invaluable as I want to set up my own company, so I’m getting all the information I need to help me form a business.”

The winner of last year’s ERA Foundation Entrepreneurs’ Award was Oxford University spin out company Bodle Technologies.

Headed by Dr Peiman Hosseini, Bodle’s research is focused on using phase-changing materials sandwiched between two layers of a transparent electrode to produce colourful films created by thin-film interference controlled by a tuneable electric pulse.

Headed by Dr Peiman Hosseini, Bodle’s research is focused on using phase-changing materials sandwiched between two layers of a transparent electrode to produce colourful films created by thin-film interference controlled by a tuneable electric pulse.

As the optical property of one layer changes the interference conditions, so the colour of the whole stack can be altered.

According to Dr Hosseini: “This technology could be used across a wide range of applications – from smart/intelligent windows to combating counterfeiting, as well as enabling low energy electronic displays in handheld devices.

Bodle Technology won last year's Entrepreneur Award for its work in developing bistable reflective displays

“We have been working hard to get demos out and have decided to focus on the display applications. Our technology doesn’t require a backlight as it uses ambient light to reflect an image, so there are massive power savings to be had.”

Based in Oxford, the company was set up in December 2015. Originally from Italy, Dr Hosseini graduated from Exeter University and carried out his post doctorate research into phase change materials at Oxford University.

Like Dr Yang and Popa, Dr Hosseini believes the help he’s obtained from the Enterprise Hub has been invaluable.

“It’s been great in terms of providing contact with experts with years’ of experience whether in one to one meetings of via networking events, seminars or events.”

Commercialisation

All three agree that while commercialisation is a challenge, the environment in the UK is very supportive

“I think, overall the UK is a great environment in which to start a business,” says Dr Hosseini. “We have been able to find venture capitalists keen to invest in our technology – admittedly this was before Brexit – and it is relatively easy to hire people.

“I was lucky that Oxford University had a strong team in place to help me. I was introduced to a number of VCs in the Oxford area who ultimately invested in the business.

“We got some seed funding to start the business and, in turn, won some competitive grants from the University.”

Dr Hosseini accepts that the technology is ‘hot’, so it is proving attractive to investors and a growing number of display manufacturers have been beating a path to the company’s doors.

He suggests, though, and both Dr Yang and Popa agreed, that universities could do more.

While Oxford, Cambridge and University College London were held up as outstanding examples of universities supporting researchers looking to become entrepreneurs, while others have departments in place to aid commercialisation, their programmes were little more than ‘box ticking’ exercises – underfunded, with only a couple of people available to manage the process.

“There is certainly a growing number of interesting programmes out there,” Popa suggests. But Dr Hosseini notes: “Too few are willing to take the necessary risks associated with commercialising innovative technologies.”

That jump certainly isn’t easy. Moving from a research environment to running a commercial business is a challenge, but one that can be overcome the right guidance and advice.

Could more universities run degree course that combine technology with business?

“How do you run a business, where do you go to raise money, what should you be doing with that money, what should be your priorities and how do you allocate resources? It does take a completely different mindset,” Dr Hosseini concludes. “You need advice and guidance and –above all – you need people to be brutally honest with you.”