“Nature does a fantastic job of making materials,” says Professor Angela Belcher of the Massachusetts Institute of Technology. “I want to use that as a manufacturing paradigm; not to make trees, because they are already doing a tremendous job, but batteries and solar cells. Future vehicles could have biological batteries.”

While these batteries will not be fully biological, they will use the self-organising properties of lifeforms to arrange inorganic materials into more complex shapes and structures than is possible using conventional top-down fabrication.

Prof Belcher’s inspiration came from abalone shells. The calcite and aragonite structures in the shell are thousands of times stronger than the minerals created more commonly by precipitation, with the inorganic crystalline materials locked into place by proteins exuded by the creature inside.

Today, we lack the skills to create structures from proteins directly. However, one way to harness the constructive power of proteins is to use organisms that can build the necessary ‘scaffolding’. Yeast and bacteria have been adapted using genetic engineering to make pharmaceuticals, such as the anti-malarial artemisinin, biofuels on a small scale and even spider silk. Viruses offer another path; the hard protein shells they use to protect the infectious DNA inside them can also be used as scaffolding.

Professor Seung-Wuk Lee, faculty scientist at the department of bioengineering in the Lawrence Berkeley National Laboratory, says: “We don’t have a good image of viruses: they usually make us sick. But there are many different types and they have amazing characteristics that other materials do not.”

In separate projects, the two groups have focused on a virus called M13. This infects bacteria, so is easy to culture and replicate, but is harmless to animals and humans.

|

|

M13’s shape is also important. Whereas many species of virus are roughly spherical, M13 is rod-shaped – a useful structure for applications such as batteries. The rods can be made to clump together in ordered rows or used to construct a rat’s nest of tubes that provides the high surface area wanted in batteries.

In the Belcher group’s initial experiments with batteries built out of M13 particles, the virus was engineered to bind readily to carbon nanotubes and coated with iron phosphate. The design took advantage of the nanotube’s high conductivity to allow electrons to percolate through a matrix more easily to the iron phosphate, transferring energy quickly. Work continues to try to use the protein shell as a way of creating structures with much higher surface area to improve the interaction between electrodes and ions in solution.

Prof Lee’s group has focused on coaxing piezoelectricity out of M13 by making selective changes to its protein coat. He points to the relatively benign nature of the proteins, compared to conventional materials used today for generating charge from mechanical force. “Those materials are very expensive to produce and composed of harmful chemicals,” he says.

The complex charge environment of the M13 virus lends itself to piezoelectric effects. Even naturally, the proteins that form the protective shell around the virus’ DNA exhibit a dipole moment. The researchers made small genetic changes to increase the number of negatively charged amino acids at one end, boosting the voltage created when the spiral structures are compressed.

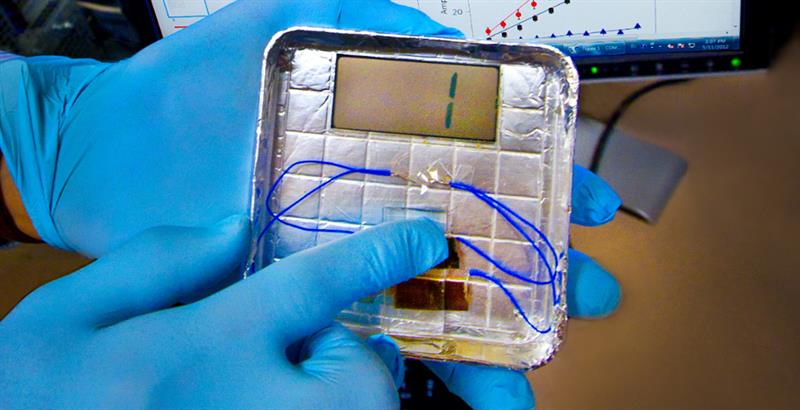

The tendency of the rod-like virus to self-assemble like matchsticks in a box made it relatively easy to build sheets of the protein rods. A 20 layer thick laminate turned out to offer the best output, producing 6nA at a few hundred millivolts – enough to drive an LCD. Within 18 months, the team had improved the efficiency of the core material 20 fold. Prof Lee says the group’s attention has now shifted to making the material suitable for wearables.

“Conventional piezoelectric materials, such as PZT, include lead and are brittle. However, our materials are environmentally clean, green and biocompatible. In addition, it is flexible,” Prof Lee says.

Although the virus particles are relatively easy to farm and harvest – all that is needed is the genetic code for the M13 mutant itself, together with a supply of bacteria and their food – the problem that faces researchers is working out how the DNA should be modified. The long-term direction is towards that of synthetic biology, where a sequence is designed on computer with a clear understanding of the protein sequences it will generate.

Today, though, the techniques rely on a combination of random mutation and evolutionary selection to identify potentially useful forms of virus. While protein production is well understood, the processes that cause them to fold into certain shapes are difficult to predict; even the prediction of simple structures is computationally intensive. But nature readily supports rapid prototyping.

|

|

“We build a phage library using random DNA inserts,” Prof Belcher explains. “We then force the phages from the library to interact with any material we want and throw away those that don’t bind. We enrich the populations of phages that do and keep the ones that make a better battery. Using these techniques, we’ve been able to assemble many different kinds of materials, including magnetics. And we’ve evolved viruses to function in solvents other than water.”

The DNA itself could prove to be a useful material in the quest to build denser, more complex integrated circuits and, potentially, DNA based machines that, to some extent, can harness electronic control. The core of the DNA helix is a stack of p-orbital rings. The electrons delocalise in these rings in much the same way as in 2D materials such as graphene. As well as helping to hold the helix together, the vertical overlap of the p- orbitals lets electrons pass easily up and down the molecule.

For years, the electrical conductivity of DNA has been controversial because it is difficult to isolate the behaviour of the molecule from the solvent – usually water – around it. The polar nature of the water molecule helps maintain DNA’s familiar structure – when treated with other solvents, the shape can flip suddenly, turning the helix inside out and changing its behaviour completely.

But experiments have shown that enzymes in cells can home in on damage to DNA, thanks to subtle changes in conductivity that emerge at the nicks. The electrical signals can travel tens or even hundreds of base pairs along the helix, opening the door to the possibility of DNA being used as an electrically active chemical sensor.

Another possibility is to use DNA sequences to build complex shapes, rather than to take part in electronic circuits directly. The conventional double-helix exploits the affinity between specific bases: cytosine (C) to guanine (G) and adenine (A) to tyrosine (T). Normally, DNA is constructed so the strands of the helix are complementary by matching the base pairs.

Pioneered by scientists such as Paul Rothemund, senior research fellow at Caltech, DNA origami works by artificially producing sequences that are not entirely complementary. The typical approach is to create a scaffold that is primarily complementary DNA to allow the double helix to form, combined with much shorter, ‘staple’ sequences that break the symmetry so they will bind to other staples on a different part of the scaffold. These staples cause the scaffold to form a series of hairpin loops that, by careful design of the sequences, can form arbitrary shapes. In the early days, these were stars, letters and smiley faces.

|

|

EUV lithography delays

Faced with continuing delays to the introduction of EUV lithography, chipmakers are looking at DNA shapes to help define masks for nanometre-scale chips. Much of the research is focusing on block copolymers that will attach to holes defined on a mask, then aggregate into larger structures with a specific shape. DNA provides the potential to create more complex shapes that will stick to particular parts of the surface because they fit a certain layout of holes. The ability of the molecule to perform limited forms of computation through DNA origami increases the number and complexity of shapes that can be built from one core strand of DNA.

But Rothemund warns of significant problems with DNA-based construction: it is error prone, something that biological organisms have learned to work with, but not yet electronics design; and DNA is fragile, it cannot survive conventional chipmaking processes.

Researchers such as Professor Michael Strano of MIT and Peng Yin, assistant professor at Harvard Medical School, have used metallic coatings to protect the DNA once it has attached to the chip, allowing it to survive chipmaking processes and temperatures. Metals readily form around the molecule, but experiments performed by the University of Newcastle found that metals tend to form beads initially. Only as more metal is added do the beads merge to form the nanowire, giving it rough edges that may prove unsuitable for the fine detail of nanometre processes.

A more effective use of DNA templates may be in forming more heterogeneous structures, Rothemund says, pulling quantum dots and carbon nanotubes into place as they are materials that conventional lithography does not deal with efficiently.

“DNA origami has the ability to not only create clusters of nanoparticles, but also to arrange them in regular grids using the directed self-assembly of DNA origami onto lithographically defined sticky patches. The prediction is that, if we can organise the clusters into grids, we can get hard-to-achieve optical phenomena like negative index of refraction at visible wavelengths,” Rothemund says.

But there is another catch, Rothemund adds. “It's easy to use DNA origami to organise metal nanoparticles ranging from 5 to 20nm in size, but the really optically exciting particles are about 40nm in size.”

Those larger particles tend to aggregate with each other, rather than stick to the DNA designed to attach to them. Further work on chemistry may yield polymers that behave like DNA, but which are more resilient to the chemical processes used in industry.

Yin says: “We expect the same self assembly principles could be extended to new materials. The most fundamental thing is that DNA is a digital polymer: you can encode a digital sequence with very specific base pairing. But it is not restricted to DNA; it can be extended to other molecules.”

Sometimes, the inspiration from biology is enough. Prof Belcher says the ClearOhm silver nanowire product developed by her start-up Cambrios was inspired by the construction of the M13 virus. “But there is no biology in this final product. We overcame the difficulties of processing the material by thinking about how biology would solve the problem.”

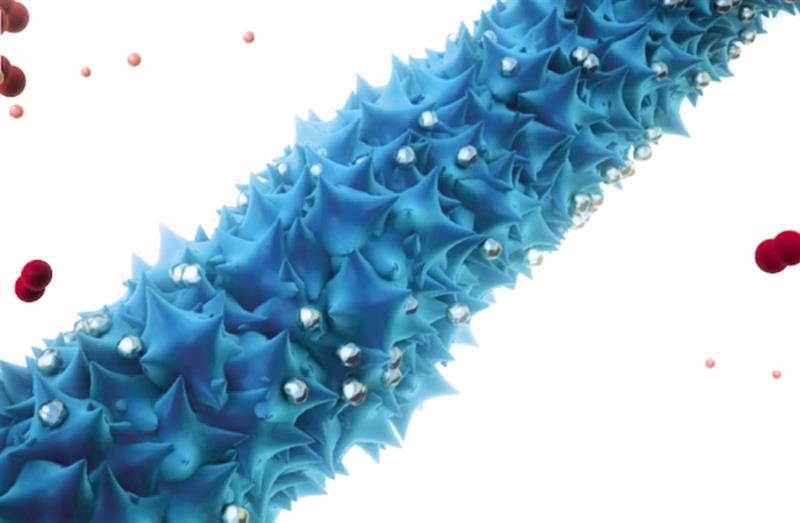

Prof Belcher's group has used the M13 virus to capture metal molecules from water and bind them into structural shapes. The spikey coating increases the nanowire's surface area.

Prof Belcher's group has used the M13 virus to capture metal molecules from water and bind them into structural shapes. The spikey coating increases the nanowire's surface area.  DNA based 'smiley' faces created by Rothemund's group using atomic force microscopy.

DNA based 'smiley' faces created by Rothemund's group using atomic force microscopy.