New approach to carbon nanotube resin composite manufacture

Researchers at Toyohashi University of Technology have developed a method for producing carbon nanotube resin composites that is said to require only 1% of the conventional amount of additive to produce electrical conductivity in the material.

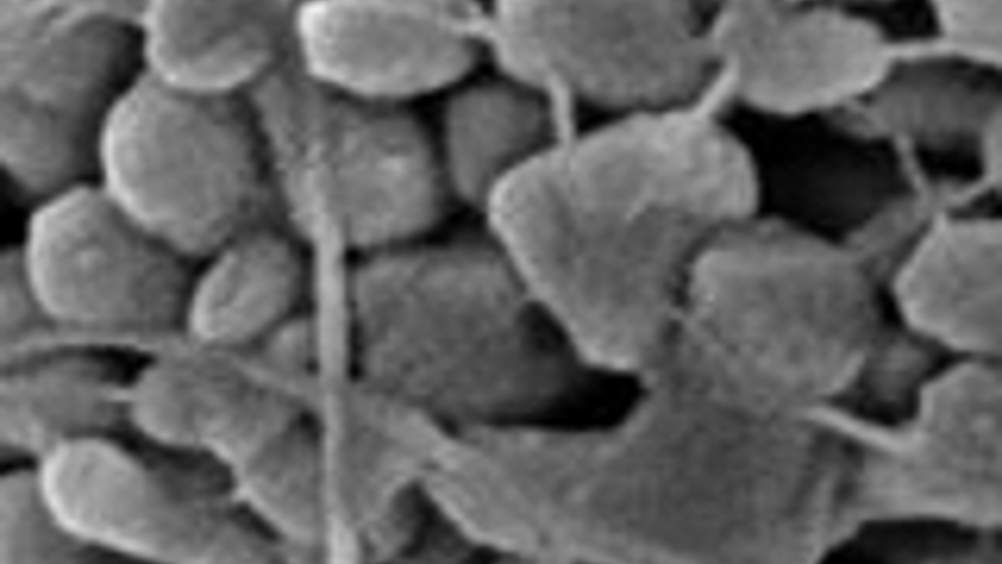

In the approach, carbon nanotubes are mixed in an electrolyte solution and added to the composite. The nanotubes are then adsorbed onto the surfaces of resin particles through electrostatic adsorption. The conductivity of the composite material can be controlled by changing the amount of electrolyte added to the composite.

According to the researchers, this approach should not only bring savings in production costs compared with conventional methods for manufacturing conductive resins, but also cut manufacturing time.

The team adds it is confident that its method will enable the production of a range of composite materials, such as metals, ceramics and polymers.