Carbon nanotubes have high thermal conductivity and are seen as a promising technology for heat dissipation from heat sources including semiconductor devices.

The material remains difficult to handle due to its fragility, however, rendering it impractical for many purposes. To address this, Fujitsu has developed a technology for laminating vertically aligned carbon nanotubes, while maintaining their original characteristics of high thermal conductivity and flexibility, as well as a technology for bonding them with sufficient adhesion.

This technology will, according to the company. help support the cutting and handling of carbon nanotube sheets, making it possible to use them as a heat dissipation material, for example, in automotive power modules for electric vehicles (EVs).

Fujitsu aims to license the use of its newly-developed carbon nanotube adhesive sheets to companies in the materials and electrical industries, and will continue to support their use in a variety of commercial applications.

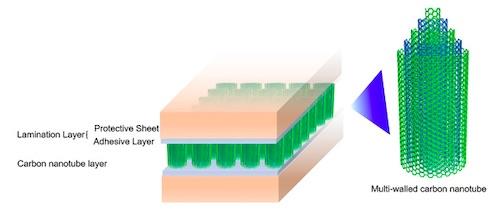

The techniques developed by Sheet Laminate Technology Fujitsu is able to laminate vertically aligned carbon nanotubes while maintaining their alignment. The laminate layer consists of two layers, a protective sheet and an adhesive layer, and has a laminate structure in which the laminate layer protects the top and bottom of carbon nanotubes.

Carbon nanotubes are difficult to use as heat dissipating materials because they easily lose their shape, but this technology is able to protect the carbon nanotubes themselves with a laminate layer, making them stable in shape and making cutting and handling easier, which was difficult with conventional technologies.

The adhesive layer that makes up the laminate layer is made of a polymer that is several microns thick. Because even a small amount of resin can cause large thermal resistance, it has become an issue in terms of both adhesiveness and thermal conductivity. By optimising three or more correlation parameters, such as the density of carbon nanotubes, the type and thickness of the resin, and the bonding conditions, utilizing knowledge of thermal resistance at the interface between carbon nanotubes and resins, it's now possible to bond carbon nanotubes while maintaining sufficient adhesive properties without impairing thermal conductivity.

The carbon nanotube adhesive sheet has thermal conductivity of up to 3 times that of the conventional indium heat dissipation material, which is known as a high thermal conductivity material, compared with measured values including interface resistance. Since the sheet is laminated with adhesive and protective layers, it can be easily cut and handled, and can be used for applications requiring adhesion.

The carbon nanotube adhesive sheet has thermal conductivity of up to 3 times that of the conventional indium heat dissipation material, which is known as a high thermal conductivity material, compared with measured values including interface resistance. Since the sheet is laminated with adhesive and protective layers, it can be easily cut and handled, and can be used for applications requiring adhesion.

These technologies will make it possible to put carbon nanotubes into practical use as heat dissipating materials, including in automotive power modules for EVs where the growing use of silicon carbide or gallium nitride as an alternative material to the more commonly-used silicon to reduce the size, weight, power consumption has resulted in issues around the heat generated due to growing miniaturisation..

Going forward, Fujitsu Laboratories is looking to license the use of its carbon nanotube adhesive sheets to companies in the materials and electrical industries. and will continue to support their commercialization and practical use.