"Silk is a very interesting material. It is made of natural fibres that humans have been using for thousands of years to make high quality textiles, but we as engineers have recently started to appreciate silk's potential for many emerging applications such as flexible bioelectronics due to its unique biocompatibility, biodegradability and mechanical flexibility," noted Assistant Professor Mostafa Bedewy of the Swanson School. "The issue is that if we want to use silk for such applications, we don't want it to be in the form of fibres. Rather, we want to regenerate silk proteins, called fibroins, in the form of films that exhibit desired optical, mechanical and chemical properties."

These regenerated silk fibroins (RSFs) however, typically are chemically unstable in water and suffer from inferior mechanical properties, owing to the difficulty in precisely controlling the molecular structure of the fibroin proteins in RSF films. Assist Prof. Bedewy and his NanoProduct Lab group, which also work extensively on carbon nanotubes (CNTs), thought that perhaps the molecular interactions between nanotubes and fibroins could enable "tuning" the structure of RSF proteins.

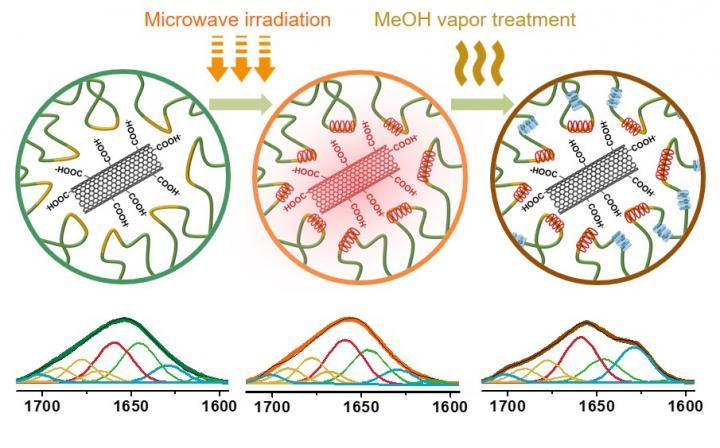

"One of the interesting aspects of CNTs is that, when they are dispersed in a polymer matrix and exposed to microwave radiation, they locally heat up," Assist Prof. Bedewy explained. "So we wondered whether we could leverage this unique phenomenon to create desired transformations in the fibroin structure around the CNTs in an "RSF-CNT" composite."

| Above is a schematic diagram illustrating the structural changes of RSF-CNT composite film exhibited during microwave- and vapour-treatment |

According to Assist Prof. Bedewy, the microwave irradiation, coupled with a solvent vapour treatment, provided a unique control mechanism for the protein structure and resulted in a flexible and transparent film comparable to synthetic polymers but one that could be both more sustainable and degradable. These RSF-CNT films have potential for use in flexible electronics, biomedical devices and transient electronics such as sensors that would be used for a desired period inside the body ranging from hours to weeks, and then naturally dissolve.

"We are excited about advancing this work further in the future, as we are looking forward to developing the science and technology aspects of these unique functional materials," continued Assist Prof. Bedewy. “From a scientific perspective, there is still a lot more to understand about the molecular interactions between the functionalisation on nanotube surfaces and protein molecules. From an engineering perspective, we want to develop scalable manufacturing processes for taking cocoons of natural silk and transforming them into functional thin films for next generation wearable and implantable electronic devices."