It would be fair to say that despite regular annual processor launches, performance increases in the high-end embedded sector have been marginal, at best, in recent years.

However, the launch, by AMD, of the Ryzen Embedded V1000 processor with its Zen micro-architecture could be said to have broken that malaise with a sizeable increase in the instructions per clock cycle - up 52%. The added availability of simultaneous multi-threading has also more than doubled the performance when compared to its predecessor.

Significantly, the Ryzen has also been designed to provide a level of performance - in terms of graphics - that had tended to be associated with high-end graphics cards with several hundred watts of power dissipation.

“With up to 3.6 TFLPOS, the Ryzen V1000 family, is able to offer that level of performance to embedded processors and the graphics are twice as powerful,” explains Maximilian Kolpak, Product Solution Manager at MEN Mikro Elektronik.

Four independent displays with a resolution of up to 4k UHD and 10 bit colour depth can be controlled and both HDMI 2.0b and DP/eDP 1.4 are supported.

In terms of interfaces, the V1000 processor includes up to four USB 3.1 Gen 2 interfaces with transfer rates of up to 10Gbps, Gigabit Ethernet and up to 16 PCIe Gen 3.0 lanes for generic expansions, 2x SATA Gen 3.0 for storage media and High Definition Audio, besides typical embedded interfaces such as UART, GPIO, I2C, LPC, SPI and SM bus.

“Despite a comprehensive set of features however, as the TDP of the V1000 processors starts as low as 12W and scales up to a maximum of 54W, it does not have a high energy consumption,” says Kolpak. “Thanks to VITA 59 support, a Rugged COM Express (RCE) module – even the 54W version – can be cooled entirely without fans. This is much more than can be achieved with conventional COM Express modules, where the limits are usually 25-35W, depending on the module size.”

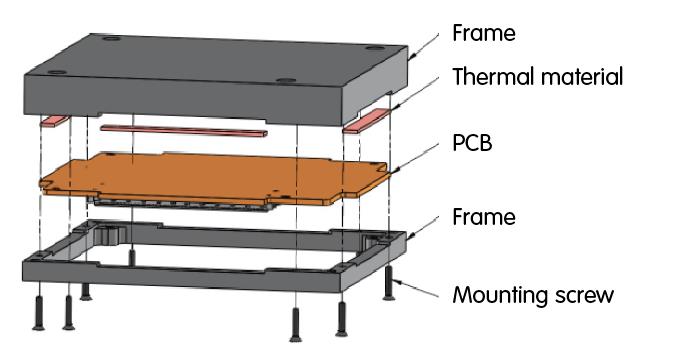

Based on the COM Express standard of the PICMG, RCE modules can offer everything that COM Express module does. The pin-out and form factor are identical. However, the VITA 59 specification adds a wing extension to COM Express modules for embedding in a standard aluminium frame (CCA), which is narrowly specified to ensure optimal thermal connection.

“Waste heat is dissipated laterally from hot spots such as the CPU, memory and voltage transformer via a heatspreader and board (PCB) to the frame, which then dissipates it via conduction directly to the surrounding housing. These measures reduce the module’s thermal resistance to the housing, reducing temperature rises by up to 5°C,” according to Kolpak.

“Overall, this leads to lower thermal stress, thereby among other things prolonging service life and ultimately, reliability.”

Because the VITA 59 compliant COM Express modules don’t need fans to cool the V1000 processors even at heat outputs of 54W, systems are much less susceptible to failures than fan-cooled systems. As a result, Rugged COM Express is suitable for systems that need to combine high-end embedded performance with high availability, especially in rugged environments such as in road, rail and commercial vehicles.

“This ties in very well with the creation of the standard, because originally Rugged COM Express was developed primarily for the railway sector, as the cooling concept benefits the requirements of EN 50155, where resilience to high temperature fluctuations in an extended temperature range is important,” says Kolpak.

RCE modules also offer protection against high electromagnetic compatibility (EMC), since the aluminium housing shields the electronics against outgoing and incoming electromagnetic radiation from all sides. In addition, conformal coating, which is a protective coating for the modules, provides reliable protection against challenging environmental conditions such as dust, moisture or even chemicals. Secure fixing of the frame on the carrier board also provides particularly high resistance to shock and vibration. Amplitudes of up to 5G for vibration and up to 50G for shocks are realistic.

In-vehicle applications

Due to the processors’ wide performance bandwidth, the application fields for these RCE modules are extremely diverse.

In the high-end sector, situational awareness applications – for instance, route monitoring with artificial intelligence for traffic sign recognition or automatic brake triggering in case of anomalies such as a fallen tree – are particularly suitable. The same applies to any mobile application – from collaborative robots and autonomous intralogistics systems to self-driving cars – that is exposed to great temperature fluctuations as well as shocks and vibrations. In such applications the comprehensive GPU support of the AMD processors, which can also be combined with discrete AMD GPUs, is a major benefit, along with the high scalability of the AMD embedded graphics.

When it comes to lower performance, the range of applications extends all the way to multi-display cockpit systems with four independent displays for self-driving vehicles and multifunctional edge systems with virtual machines or even robust mobile devices for maintenance using augmented reality.

A module for extremes

MEN Mikro Elektronik is a manufacturer and initiator of the VITA 59 specification for COM Express, and has developed the CB71C module which is fully compliant with the COM Express Type 6 pin-out and is available as an ultra-robust Rugged COM Express module including a CCA aluminium frame that acts as a heat sink and protection against harmful environmental effects.

With a scalable selection of V1000 processors with 15 to 54W TDP and supporting up to 32GB of soldered DDR4 RAM; optional ECC for safety-critical applications; 16GB on-board eMMC providing space for the OS and applications as well as 11x PCIe Gen 3.0, 3x USB 3.1. Gen 2 (10Gbps), 3x USB 2.0 along with 4x DisplayPort and 1x Gigabit Ethernet, the module is capable of supporting all the high-speed interfaces of the COM Express Type 6 specification.

| The mechanical design of the VITA 59 compliant Rugged COM Express modules is signifcantly more robust than traditional COM Express cooling solution |

In addition, the CB71C integrates a powerful board management controller with monitoring functions for safety-critical applications. To guarantee high data and application security, it has a Trusted Platform Module and provides real-time memory encryption on the hardware side to protect against physical and inter-VM memory attacks.

“There are a variety of applications that can be implemented with standard COM Express Type 6 modules. That’s why the new CB71C is also available in the regular CB71 COM Express version.

“Meeting the same high demands that are placed on Rugged COM Express, it is developed and manufactured to the highest quality standards, such as DIN EN ISO 13485 for quality management and DIN EN ISO 14971 for risk management,” says Kolpak.

“There are a variety of applications that can be implemented with standard COOM Express Type 6 modules .” - Maximilian Kolpak |

These MEN modules don’t require any special or complex qualification, since all that changes is that the ‘wings’ are dropped and the CCA is replaced by a classic COM Express cooling solution.

“Such quality standards are ideal for applications that require high availability, robustness, and quality; or industry-specific certifications that need to be supported by high-quality documentation and generally require an end-to-end audit trail,” explains Kolpak.

Customers for these modules are found in sectors ranging from medical technology and power plant maintenance, to industrial automation as well as payment, ticketing and vending systems that rely on high quality and long-term stability.