The Institute’s work is focused on the way in which railway vehicles interact with the track, addressing such aspects as suspension performance, wheel-rail contact, traction and braking.

Part of the University’s School of Computing and Engineering, the IRR has helped to develop a new system called Tracksure, which can capture and then transmit information about the condition of the rails and of the rail bed.

Developed as a joint research effort with Siemens, Tracksure is a response to the Remote Condition Monitoring Competition set up by the Rail Safety and Standards Board and Network Rail.

According to senior researcher Dr Farouk Balouchi, pictured: ”The IRR has developed a range of tools and techniques to better predict any deterioration in rails and wheels, helping to improve the safety and reliability of the rail network, as well as reducing running costs. In this way, it could improve the overall performance of the railway system.”

By using sensor technology, Tracksure can detect under-track voids – essentially gaps that can open up between sleepers and ballast.

“The rail network in the UK has seen a significant increase in traffic over the past 10 years, which is not only putting pressure on the overall capacity of the system but also on the ability of the network to manage maintenance,” explains Dr Balouchi. “Current track monitoring vehicles are limited as to where they can be deployed and can’t travel over branch or low frequency lines.

“Our remit, working with Siemens, has been to alleviate pressure on track recording vehicles and our solution was to use existing vehicles to monitor the track efficiently.

“Most of the problems on the network occur with high value assets. These include: switches and crossings and where the track transitions to bridges,” he explains. “If voiding occurs, services can be delayed and train operators incur fines. We want to be able to identify problems quickly and efficiently so that lines don’t have to be closed and tracks don’t break, which could lead to accidents and fatalities. We need to maintain the track’s condition and ensure that services aren’t disrupted.”

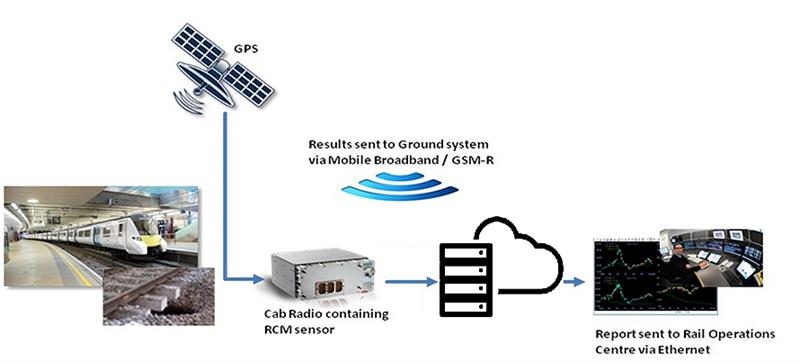

Every train in the UK is fitted with a GSM-R cab portable radio system and, as a result of the work by Siemens and IRR, it is possible to retrofit an inexpensive sensor card to these radios to pick up vibrations and transmit information to a control centre that will be able to identify voids.

“There are 10,000 radio’s in around 5,000 trains – one radio either end of the train. The system works on three levels: providing a simple warning (Green/Amber/Red) of void severity and location in a csv file output; detailed output of void location acceleration data via train wifi and then a ground system post processing of acceleration for trending and predictive maintenance,” says Dr Balouchi. He continues, “For the amount of money being invested, we will see an impressive return in terms of the data we’re able to generate.”

The IRR has been involved in the development of an algorithm that is capable of allowing sensors to detect these under-track voids and this algorithm is then programmed into the Tracksure sensors.

“Tracksure has been conceived as a reliable monitoring system that is non-intrusive, yet gives analysis for the entire rail network, improving train safety, network reliability and passenger comfort,” says Dr Balouchi.

“It has been a very challenging project and we used extensive simulation to identify what type of sensors would be required and what accuracy and sensitivity would be needed for the prototype.”

The algorithm that has been developed is capable of processing large quantities of acceleration data in a short space of time and can detect the location and severity of any potential track voids.

“It can, for example, process 20 minutes of acceleration data in just 1s,” says Dr Balouchi, “which gives the system the capability to do many other things.”

For example, in addition to detecting voids, the sensors could also provide early warning of problems such as corrugation of the track or wheel flats – distortions in wheel shape caused by factors such as the lack of adhesion.

Vehicle suspension faults could also be picked up by the sensors.

“We think that Tracksure is a remarkably elegant and simple solution,” he suggests. But while it may be a simple solution, it was challenging to deliver.

An overview of the Tracksure sensor system

Design challenges

“Deploying sensors in this way has proved almost impossible to do successfully,” Dr Balouchi notes. “We needed to eliminate the effects of the various levels of suspension that are designed into vehicles in order to provide a smoother ride. Most vehicles have a primary level of suspension but will also be designed with bogey level suspension, which is essentially an air bag.

“The vehicle’s suspension effectively eliminates high frequency signatures, making it a lot harder to detect voids. So, by improving the quality of the ride, you actually reduce access to the information needed to monitor irregularities in the track – it made coming up with a workable solution particularly difficult,” Dr Balouchi explains.

What the team did was to use simulation, together with signal processing and analysis, to isolate and then create a void signature.

“We used signal processing techniques, such as multi-resolution analysis, to break down the signals we received into their component parts in terms of the energy available at certain frequencies,” he says. “By doing this, we could identify the signal components related to the void and disregard irrelevant components.”

He notes this had the added benefit of having to deal with less data, meaning that the algorithm could work more efficiently.

“Tracksure is relatively simple, comprising sensors, a MEMS tri-axis accelerometer using a roof top GPS aerial for location detection and a standalone quad core processor. Combined, they can process information very quickly,” he explains. “More importantly, the processed data can be stored, sent to a ground system, which can then send that data back to Network Rail for further analysis.”

While the algorithm can categorise different voids, the system can take advantage of machine learning techniques, allowing it to disregard anomalies and to narrow down statistically the location of track problems.

Siemens is looking to install the system in all of its trains, not only in the UK, but also globally.

Simulation tools were critical to the development of Tracksure with the IRR deploying vehicle dynamics software (VAMPIRE), vertical track modelling and MATLAB for simplistic vehicle modelling.

IRR is now helping Siemens to further improve the quality of void detection accuracy by making use of multiple trains running over the same section of track.

“We are looking to see how better we can generate and use data through additional signal processing,” Dr Balouchi says. “We are also looking at how machine learning could be used to govern the algorithm over time, by fine tuning certain parameters to improve the accuracy of the sensor.”

Beyond that, Siemens and the IRR are assessing how the concept could provide levels of ‘big data’ that could further enhance and improve levels of network safety and cost-efficiency.