Silicon still accounts for the majority of solar cell production. As that has to be purified from sand – a process that involves cleaving the incredibly stable silicon-oxygen bond – the energy inputs can be huge. The energy required can reach 500kWh per square metre of solar-panel area for the highest-performing monocrystalline form of silicon – an amount that pays back normally within several years of operation. Multicrystalline silicon more or less halves the energy cost of silicon purification, but is about 25% less efficient at capturing photons.

Bringing costs down

Although improved manufacturing can bring the energy cost down, the absorption profile of silicon means that it needs to be made relatively thick to improve the probability of harnessing each photon that breaks through the surface. Thin-film cells made from lower-grade and even lower-efficiency amorphous silicon have largely given way in the past decade to successive waves of more capable chemistries. First came cadmium telluride (CdTe), which was propelled into mass production by First Solar. Despite cadmium’s toxic nature, governments have treated the pollution risk from these solar cells to be minimal as long as old panels are recycled properly.

A competitor to CdTe is a mixture of copper, indium, gallium and selenium (CIGS) that encouraged even semiconductor foundry TSMC to buy into solar production at the end of the last decade. Although it managed to create a module with record CIGS conversion efficiency of 16.5%, the company was priced out of the business and quit five years after entering the market.

Another way to deal with the problem of the high cost of purifying semiconductor materials is to try to reduce the surface area. For years, III-V and germanium-based solar cells have boasted higher efficiency than silicon, but are more expensive to make. The answer is to use a concentrator, in which a lens is placed over a small die of the material to focus more light onto the collector. But, as with someone aiming the sun ray’s through magnifying glass, high temperatures create their own reliability problems.

As production ramps, most existing technologies other than silicon face the problem of material availability. Tellurium is a by product of copper mining, so is reasonably easy to obtain but relatively uncommon. In 2000, it cost around $35/kg. A decade later, the price peaked at more than $600/kg before settling back to around $300.

CIGS manufacturers have similar problems, not just with gallium and selenium, but especially indium, where they compete for supplies with flat-panel display manufacturers. So researchers continue to pursue other options, preferably materials that do not suffer from such constrained supplies. A cheaper choice that shares many of the same properties as CdTe and CIGS is iron disulphide – fool’s gold – and neither of those elements is going to be in short supply.

On paper, iron disulphide looks good in terms of both band gap and optical absorption, but the material showed less than 3% quantum efficiency when tried as a photovoltaic. The problem is many common crystal phases have smaller band gaps than the material’s nominal 0.95eV, which slashes overall efficiency. The hope for a viable use for fool’s gold in solar rests on advances in nanotechnology that can avoid growing dud crystals.

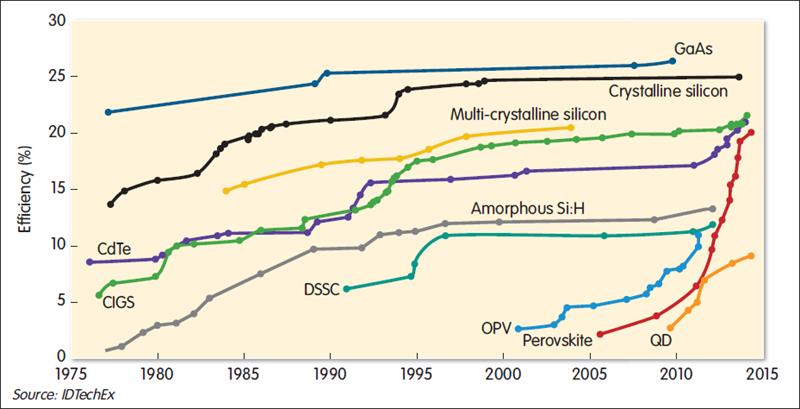

While the efficiency of a range of PV technologies has improved in the last four decades, none matches the improvement shown by perovskite solar cells

While the efficiency of a range of PV technologies has improved in the last four decades, none matches the improvement shown by perovskite solar cells

Organic materials

Given the carpet of green that covers much of the world, organic materials should also be good, cheap candidates for use in solar cells. However, biotechnology has not progressed to the point where it can harness the same kinds of electrochemical reactions that take place in chlorophyll-loaded living cells.

The increased interest in organic semiconductors for making large-area electronic circuits – such as cheap RF tags and displays – also helped drive research into solar cells made on similar organic chemicals. The same solution-based chemistry and coating processes could support lower-cost production than is possible with many of the other inorganic solar technologies.

Despite good progress in the early 2000s, efficiency for small-scale ‘hero’ cells based on organic compounds failed to match the performance of even the cheapest, amorphous form silicon. They have, so far, topped out at around 10% efficiency.

Some researchers and startups involved in organic research have switched their focus to inorganic materials that can be spin coated onto a substrate and which seem to be highly compatible with interface layers developed for plastic photovoltaics. The current favourites are combinations of elements – sometimes including small organic molecules such as methyl-ammonium – that form a cubic crystal structure resembling the calcium-based mineral perovskite.

Perovskites became a major focus in photovoltaic research at the start of this decade because researchers could improve efficiency much faster than any other technology so far. Some of this may be to do with the experience with chemically similar organic materials and the production processes developed for them. Even so, efficiency for perovskite based laboratory cells quickly surpassed that of organics and currently challenges multi-crystalline silicon and thin-film chemistries at around 20%.

As with other technologies, the efficiency of cells suitable for integration into modules lags. Earlier this month, IMEC spinout Solliance demonstrated a design with a reported efficiency of 10%, becoming the top performer so far. The group reckons 15% is achievable, although there is, as with organic materials, a big challenge in developing barrier materials that will last for more than a few years.

As the best perovskite materials so far need to use lead, the need for a reliable barrier materials is more than just one of useful lifetime. The barrier needs to make lead contamination of the environment highly unlikely – with recycling used to recapture the poisonous metal before disposal. Work using computational materials design to select a crystal that has similar, but less carcinogenic properties, may yet yield an efficient alternative.

Another potential drawback with perovskite chemistry, in common with organic and silicon, is that it will probably need thicker layers than those used in the thin-film technologies such as CdTe, which will increase production costs. That could still be more than offset by the elements themselves being cheaper to extract by miners.

Combining technologies

Rather than trying to eke a few more percentage points out of the quantum efficiency of a given solar technology, another approach is to combine two or more technologies in one cell or module. If they have different band gaps and are transparent enough to let enough light pass through, they will capture a greater proportion of the incoming photons. This seems to be one way in which organic photovoltaics may stage a comeback at the research, though even combination cells have only reached around 13% efficiency – a record set by Heliatek in February – versus close to 50% for the best stacks of heterojunction semiconductors.

Combination with perovskite layers may mean that organic photovoltaics still stand a chance, just as long as the industry can come up with long-lasting barrier layers. Whichever individual technology wins, the huge areas needed for an even larger rollout of solar generation will tend to favour the technologies with the lowest material cost, even if that means a more complicated assembly process.