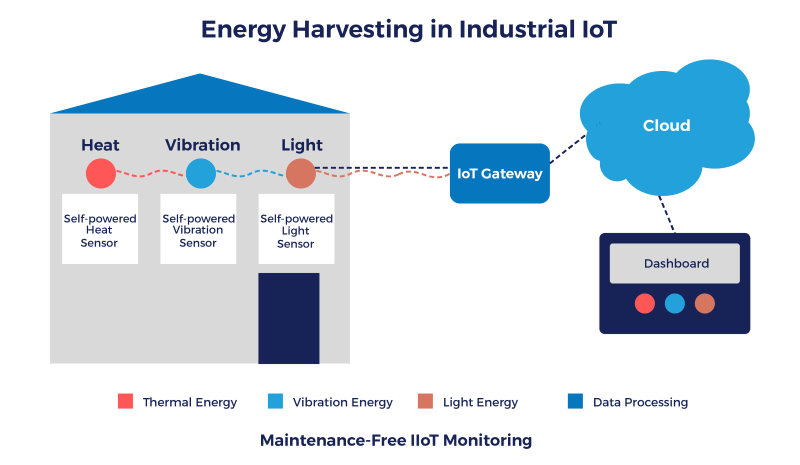

The Industrial Internet of Things (IIoT) is transforming industries worldwide but one of the toughest challenges facing device deployment continues to be power management. Traditional battery-powered devices often require frequent maintenance, which can be costly and impractical, especially in remote or hard-to-reach locations.

This is where energy harvesting technologies come in, enabling self-powered devices that can operate indefinitely without battery replacement.

Energy harvesting captures and converts ambient energy from the environment into electrical energy allowing devices to generate power from various sources, such as vibrations, heat, light, or kinetic energy, eliminating the need for traditional power sources.

Energy harvesting presents numerous advantages, such as Reduced maintenance costs, deployment flexibility, reliability and scalability as well as the environmental benefits of reduced electronic waste in landfills

However, implementing these technologies in IIoT devices come with several concerns that engineers and product designers must address.

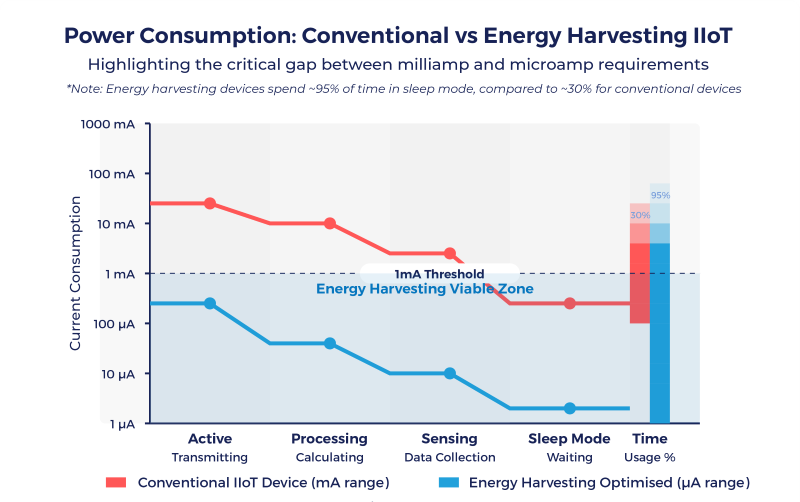

Firstly, many designs are simply not suitable for energy harvesting, as they use tens of milliamps, or more, in normal operation. Whilst this is feasible with a solar array, in many cases the size or location does not allow for a large enough panel. Other forms of harvesting e.g. piezo, RF and thermoelectric are unlikely to be able to power such a device.

So, is energy harvesting even feasible? If you’re trying to stream video over a 5G link, it’s very unlikely that energy harvesting is for you! If your product uses microamps, with pulses in the milliamp range when transmitting, it could be a good fit.

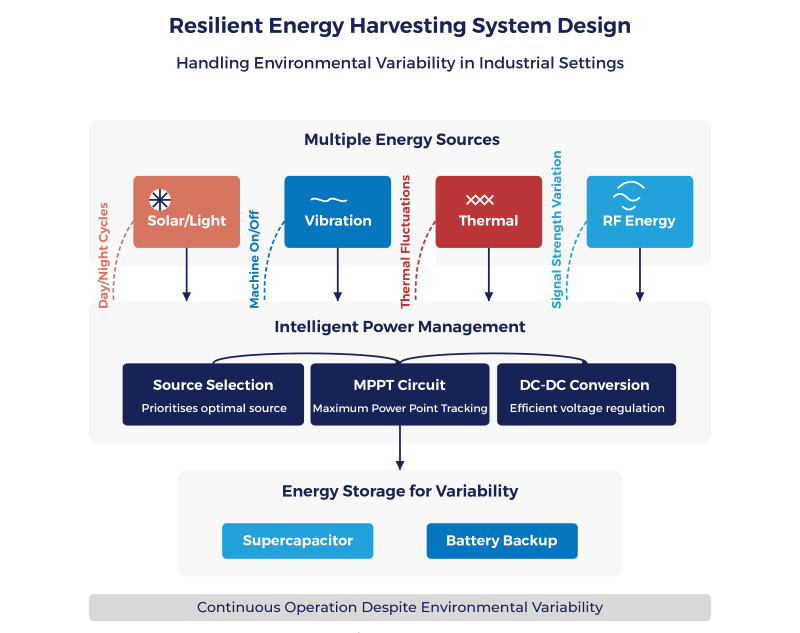

Energy harvesting doesn’t remove the need for energy storage in most cases. Let’s say you’re using a PV source, but need to be able to operate in the dark. You’re going to need to store energy from the source when there is light available. You must also size your storage and PV source such that it can provide enough energy to not only power the device during daylight, but also have enough spare to run through the night.

Storage typically means either capacitors or batteries. The former are suitable for very low power devices and the latter for higher power devices. There are many types of battery and capacitor (this is outside the scope of this article); suffice to say that everyone who owns a mobile phone will understand that rechargeable batteries have themselves a finite lifespan and operating temperature range and the same is true for capacitors.

Both need rating - not only for the initial product life, but over the operating lifetime, which usually means overrating them.

Efficient energy conversion

Energy conversion efficiency remains a key requirement across all harvesting technologies. Current thermoelectric generators generally operate at only 5-10% efficiency, while indoor photovoltaic cells might achieve 15-25% efficiency under optimal conditions which means that harvesting systems must be carefully designed to maximise energy capture and minimise losses.

The power management circuitry plays a central role in optimising efficiency, as it must handle irregular and unpredictable energy inputs while maintaining stable power output. Advanced power management integrated circuits (PMICs) specifically designed for energy harvesting applications have emerged, incorporating features such as maximum power point tracking (MPPT) and ultra-low-power DC-DC conversion to extract the maximum available energy from ambient sources.

Industrial environments are rarely stable, posing challenges for energy harvesting systems that rely on consistent ambient energy sources. Vibration-based systems may encounter machinery that operates intermittently, while light-based systems must contend with varying lighting conditions. This variability requires robust energy storage solutions, such as supercapacitors or small rechargeable batteries, for continuous device operation during periods when harvested energy is unavailable.

Creating truly self-powered IIoT devices requires a fundamental shift in design approach. Every aspect of the device must be optimised for ultra-low power consumption, including: MCUs that support multiple deep sleep modes; sensors with low sampling power and rapid start-up times; communication protocols optimised for minimal transmission power and firmware designed to maximise sleep time while maintaining functionality.

In many cases, this means rethinking data acquisition and transmission strategies. Rather than continuous monitoring, energy-harvesting devices often employ event-based sensing or scheduled wake-up patterns to conserve energy while still delivering valuable insights. The software aspects of energy harvesting systems can be every bit as important as the hardware design when creating a system that works in the real-world.

Another practical challenge is the physical integration of energy harvesting components into IIoT devices. Harvesting mechanisms often require specific positioning or orientation to maximise energy capture. For example, vibration harvesters need to be aligned with the primary vibration axis, while photovoltaic cells require exposure to light sources. These requirements can conflict with other design constraints, particularly for devices intended for retrofit applications in existing industrial equipment.

Addressing these issues requires a holistic approach to device design, that considers the entire power architecture, from generation to storage to consumption. Successful implementation demands collaboration between mechanical, electronic, and software engineers to create truly optimised solutions that can reliably operate in industrial environments for years without maintenance.

Is energy harvesting feasible?

Consider an example of an IoT device powered by ambient indoor light, that communicates over Zigbee. The ANYSOLAR KXOB25-02X8F is an efficient solar cell with an expected output of 2.5 mW of power in average office lighting for its 1.2 cm2 area.

Let’s assume that we have 10 cm2 of solar photovoltaics on our device, and our environment sees 10 hours of light per day. If we select an appropriately sized energy storage component, such as a supercapacitor or rechargeable battery, then we can expect to be able to store 750 joules of energy per day.

For the Zigbee transmitter, we can use the SiLabs EFR32MG27 which is a microcontroller with an integrated 2.4 GHz radio. The sleep current of the device is less than 10 microwatts; however, any realistic IoT device would have additional quiescent power draws from the additional sensors and peripherals needed for it to perform its purpose.

We can estimate the average sleep power consumption of the system as 200 microwatts. A short Zigbee message suitable for IoT could last 5 seconds to transmit. Using these values, we can calculate that our indoor light-powered Zigbee device can connect to its network on average about 200 times per hour, powered entirely by ambient energy harvesting.

This calculations method can be used to estimate the performance of any combination of energy harvesting and wireless communications technology, to assess the viability of IoT concept devices.

Outdoor solar energy harvesting will provide by far the most power for an IoT device but indoor light can still be effective enough for multiple transmissions per hour. One of the lowest-power wireless transmission methods is Bluetooth Low Energy, which enables the most frequent data transfers. However, it also has the shortest range.

In contrast, Narrow Band Cellular has the longest range by using the same infrastructure as mobile phones to connect to cellular tower that may be kilometres away. It is also the most power-hungry, however, allowing only infrequent connections for devices powered by energy harvesting.

Thermoelectric and Radio Frequency (RF) energy harvesting supply small amounts of power in very specific environmental conditions but can still be used for practical solutions in industry.

With so little to work with, we are no longer considering the repetition of transmission, but the maximum length of a single transmission, which is in the scale of microseconds. This is too short for most wireless protocols, but some, such as Bluetooth LE, can last just long enough to send a few bytes of data before running out of energy.

The Future of energy harvesting in IIoT

Recent advances in materials science are revolutionising energy harvesting efficiency. New piezoelectric materials deliver improved vibration harvesting capabilities, whilst perovskite solar cells show remarkable potential for indoor light harvesting with significantly better efficiency than traditional photovoltaics. Miniaturisation is accelerating, with nanoscale generators like triboelectric nanogenerators (TENGs) converting even minute mechanical interactions into usable electricity.

Tomorrow's industrial environments will increasingly rely on hybrid harvesting systems combining multiple energy sources all managed by intelligent power management circuits that select optimal sources based on environmental conditions. This diversification ensures continued operation when primary energy sources become temporarily unavailable.

With the rapid growth of edge computing, energy harvesting will feature more prominently in IIoT applications as it’s simply the most practical way to power remote processing units without the headache of running cables or constantly swapping batteries.

What's particularly exciting is how today's ultra-low-power processors work hand-in-hand with energy harvesting technologies. This powerful combination enables sensors to process data right where it's collected, filtering out the noise and sending back only what matters.

Industry standardisation is emerging through consortiums establishing consistent testing methodologies and performance metrics and industrial automation companies like Texas Instruments and ABB are incorporating energy harvesting into their product roadmaps, driving costs down through economies of scale.

Energy harvesting represents a transformative approach to powering the IIoT but while issues remain, particularly in matching power requirements with harvesting capabilities, the trajectory of technological development suggests that an increasing range of industrial applications will become viable for self-powered operation in the coming years.

Author details: Dunstan Power is the co-founder and director, ByteSnap Design