Artificial Intelligence (AI) and the Internet of Things (IoT) are natural companions: IoT technologies provide the platform for capturing and concentrating data from huge numbers of devices dispersed throughout a building, factory, infrastructure, supply chain, the ambient environment, or on movable assets such as vehicles or shipping containers. AI can transform that data into valuable insights and automated responses driven by machine learning, enabling new and hitherto impossible services.

Combining the two, leveraging AI in the cloud as well as embedded in IoT edge devices, creates the Artificial Intelligence of Things (AIoT). This can be a powerful facilitator for the digital transformation that organisations need to reshape their activities and services to become more efficient, more insightful, and more agile.

The AIoT value-add

By bringing learning capabilities to IoT solutions, AIoT can add value in numerous scenarios. Water utilities, for example, incur significant costs due to leaks. These may occur almost anywhere in the network but can be very difficult to detect and pinpoint. With AI embedded in edge devices and/or in the cloud, a system can learn the water usage behaviour of properties, including the signatures of items such as taps, washing machines and showers, and use that knowledge to identify leaks and pinpoint their location.

In an industrial context, AIoT can accelerate equipment vendors’ transition to service-based models based on customers’ usage. One potential service that’s topical at the moment is predictive maintenance, which promises major cost savings for service providers and greater efficiency and utilisation for customers. An AIoT solution can not only sense symptoms such as abnormal vibration or bearing noise that can indicate impending failure of a motor system but also learn to diagnose and accurately predict the time of failure. With that information, the provider can schedule maintenance for a time that is convenient for the customer and fits with the service team’s schedule.

Realisation challenges

The types of organisations looking to develop AIoT solutions are incredibly diverse, encompassing, for example, specialists and start-ups creating packaged platforms or services, as well as end-user companies such as large industrial corporations seeking to infuse AIoT capabilities into their operations.

AIoT devices and platforms designed for manufacture require hardware design, embedded processing, wireless technology, hybrid hardware-/software-based cyber-security, data aggregation through gateways, and cloud or hybrid edge/cloud machine learning. There are often additional challenges, such as implementing robust wireless connectivity in difficult environments, and minimising latency for critical applications through the selection of appropriate edge technology.

Above: Infineon's SLM97 is a high performance security controller

Above: Infineon's SLM97 is a high performance security controller

The skills and resources necessary to complete these projects typically do not reside within one organisation. Cyber-security, for example, is a highly specialised field that demands intimate understanding of best practices and up-to-date knowledge of the latest threats. That’s a considerable investment in expertise that smaller companies cannot sustain, so Arrow’s IoT business established a strategic partnership with Infineon and Arkessa to facilitate cellular connectivity in IoT applications, protected with Infineon’s secured hardware controllers based on the GSMA Embedded Subscriber Identity Module (eSIM) specification.

In addition, smaller companies often need help with ideation and developing product requirements, and may need to outsource design and manufacturing. Arrow has a network of partners that can provide engineering services to help with technology selection, design-for-manufacturing and assembly and test, that can resolve skill shortages, reduce budgets and accelerate a product’s time-to-market.

AIoT platform creation

Organisations looking to leverage AIoT themselves as a means of achieving digital transformation face altogether different types of issues. With the correct guidance on the selection of devices and technologies, they can connect physical sensors and assets in all locations and scale those networks as growth demands.

The big challenge comes when users start generating data. Understanding the data science and data trends to implement actuation and learning is where many customers have massive skill gaps. Many strands must be woven together including accessing data, aggregating that data – in the cloud or on premises – analysing it and then using the result to feed back into improved operation. All of this must be achieved at large scale and in a cost-effective manner. Moreover, AIoT requirements of industrial applications will be completely different from those of building-management or transportation solutions.

To address these challenges, Arrow has created a number of vertically oriented platforms and solutions that combine turnkey IoT devices with selected cloud services. One example is the smart airport asset-management solution recently announced with IBM. The solution brings together Arrow-designed and sourced sensors and gateways, the IBM Watson IoT platform, and IBM Maximo enterprise asset management software. The solution is optimised for assets such as escalators, moving walkways, baggage handling systems, to give airport operators the insights they need to prevent downtime and enhance the traveller experience.

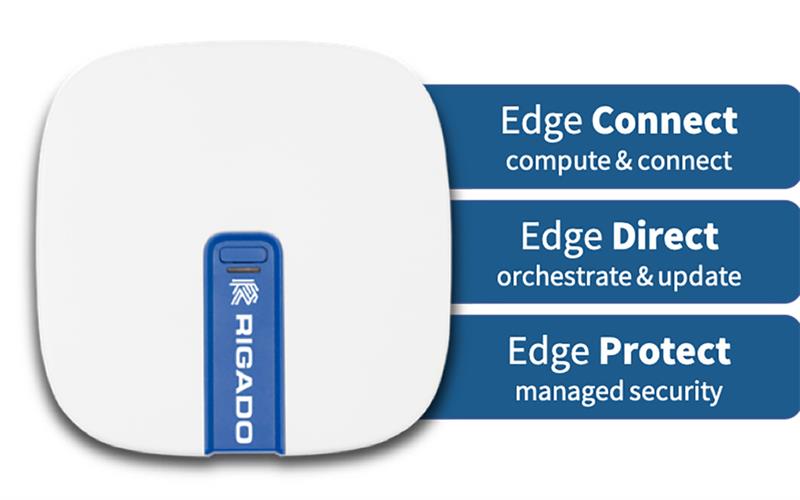

On the other hand, managers of commercial and retail spaces face building-occupancy challenges that can affect both corporate revenue and user experiences. AIoT can help take the guesswork out of understanding how spaces are being utilised in real-time, but this is a multi-faceted challenge that demands a combination of secure IoT connectivity, visualisation and analytics solutions developed specifically for smart building applications. For this, Arrow brought together the Rigado Cascade connected hospitality solution and Iconics building-automation solution, again integrating Arrow-designed and sourced IoT sensors, gateways and software, to create an occupancy management solution that also leverages the Microsoft Azure IoT hub.

Industrial organisations can have very specific requirements, such as the predictive maintenance challenge mentioned earlier. Arrow partner ADLINK has an edge IoT solution for machine condition monitoring that can deliver continuous vibration measurement for rotating machinery and equipment. Working with ADLINK and Microsoft, Arrow provided additional services and resources to complement and connect this device – the MCM-100 - to let customers reliably analyse and visualise real-time event data in the Azure Cloud.

Conclusion

AIoT presents exciting opportunities for companies ranging from specialised developers of connected IoT devices, to platform builders, solution integrators, and system owner/operators. Success calls for competencies that extend across the complete IoT and AIoT stack, which can only be achieved through cooperation between trusted partners that between them can assemble the requisite skills covering sensing and connectivity through to data aggregation and analytics.

Author details: Andrew Bickley, Director of IoT, Arrow Electronics EMEA