element14 plays an important role in the partnership because of our proven expertise in managing similar projects designing and manufacturing development kits for similar projects in our strategic alliance program.This project is a great example of the activity required to bring a new board to market.

element14 became aware of the project back in February 2015 and put forward a proposal to support with the design, cost optimisation and manufacturing of the board.At this stage there were a number of unknowns and element14 was invited to engineer away this uncertainty acting as arbitrator between the needs of the working group and the practicalities of manufacture.Our role in the project is to take the prototypes for the BBC micro:bit based on the ARM mbed reference designs in the mbed Hardware Development Kit (HDK) and optimize them for mass manufacturing..

Design

Internally and through acquisition partners we have the skills and expertise to bring a board like the BBC micro:bit to market.The initial design called for a complex and expensive routed design. However, because of the quality of element14's V-score process, the cost of the board was able to be significantly reduced, without sacrificing the quality of the finish.

| |

Visual appearance was also important on this board.In most development kit designs the appearance is secondary to the functionality but as this board is aimed at children it needed to be both functional and friendly.element14 worked with the BBC, ARM, Microsoft and design company Technology Will Save Us to understand the aesthetic and usability considerations of the board, and assist with realising the manufacturing realities behind these design decisions.

Cost Optimisation

Cost optimisation is key to all board designs.Suppliers will have an idea of cost and retail price per board before the project starts.In this case the BBC was aiming to reduce the cost of the board to a point where, through the contributions and donations of the projects' partners, the board would be provided at zero cost to every 11 and 12 year old in the country.To assist in this, element14 was able to use its considerable influence with various supplier partners to leverage economies of scale to benefit this project.This is possible in higher volume production runs, but with smaller projects this can be more difficult.This economy of scale is applied to all our development kit designs to ensure the boards are created to be commercially viable.

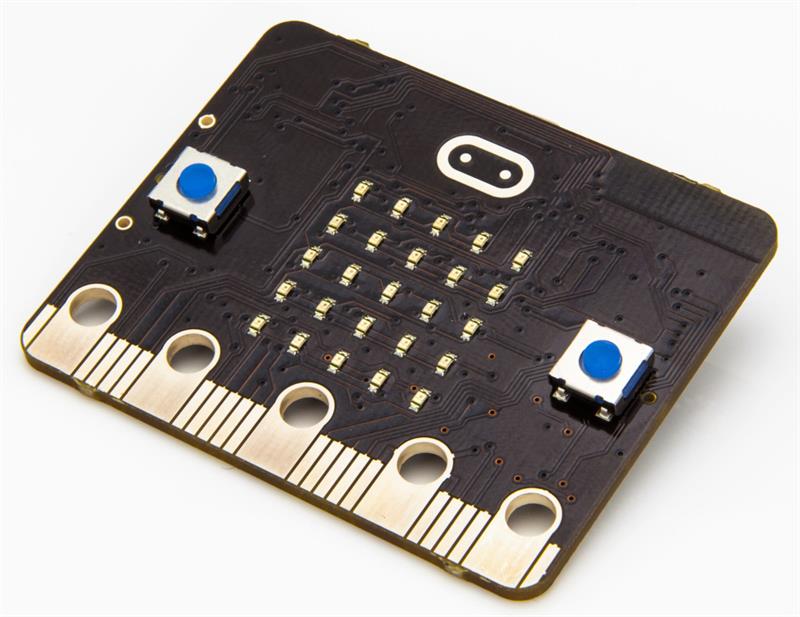

| I/O ports on the back of the BBC micro:bit Front Back |

Manufacturing

The project has to be manufacturable at scale.We were able to work with our many manufacturing partners to find a suitable organisation to manufacture the board in the quantities that are required, and within the aggressive timelines of the project.In this case we are working with IO Note in China.

As the design was being created in the UK, to avoid unnecessary delay, initial prototypes were manufactured in the UK.This allowed the partners testing early prototypes and writing the key software components to de-bug quickly and move onto the next stages of the design; we call this quick turn manufacturing.

Once the prototype is approved the next step is to manufacture a first batch of 10 – 20,000 boards, which will be sent to early adopters to test.

Final mass production will occur shortly after and the million boards should be in schools in the autumn.

Gary Atkinson, Director of Emerging Technologies at ARM said: "The BBC micro:bit will prove a huge hit with young people as the uses it can be put to are truly exciting, including creating new Internet of Things devices. Ultimately its success will also depend on its life beyond the 2015/16 rollout, and the original micro:bit design by ARM and its partners combined with the optimization excellence of element14 has ensured it is a highly affordable product that can create a niche for itself in the education market."

Conclusion

You can see from this very short snapshot that there are many layers to designing and manufacturing a new board.Hopefully you can also see how element14 has supported managing the manufacture of a project in time and at cost through its considerable market experience.Our role in this project as well as those with our strategic partners is to turn the initial idea into a manufacturable reality.

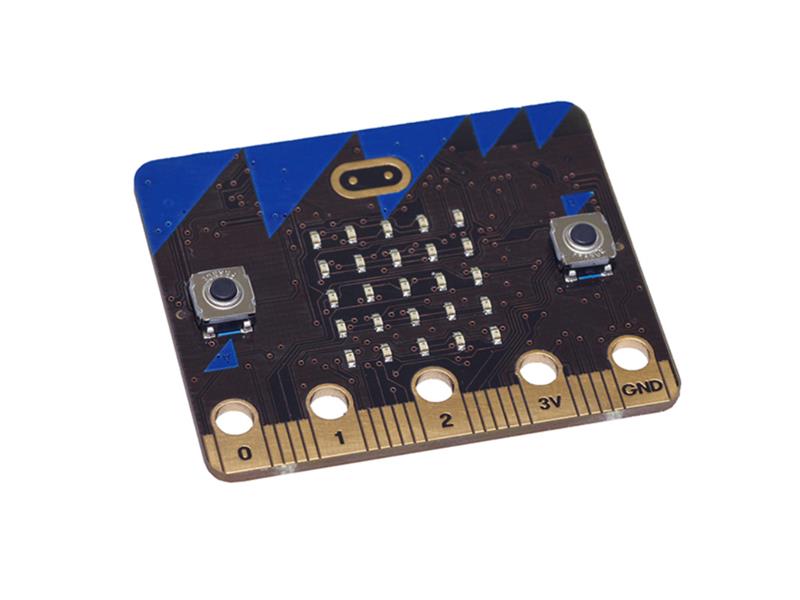

The BBC micro:bit in blue

The BBC micro:bit in blue