There’s not always a clear demarcation between applications, products or industries better suited to rigid interconnect systems and those better suited to flexible. Applications for both technologies have a wide overlap, and both enable a shift from a single PCB in a 2D aspect to a multi-PCB solution with infinite possible topologies and product shapes.

When choosing between fixed and flexible, however, there are tendencies — reasons why one or the other may be the better option in certain circumstances. The right choice will always be specific to the product/solution you’re aiming to develop together with the production method, the mounting position of PCBs relative to each other, operating environments and electrical parameters. We would always recommend a conversation to address the specifics of each project. In general, however, here are some reasons why you might tend towards one or the other.

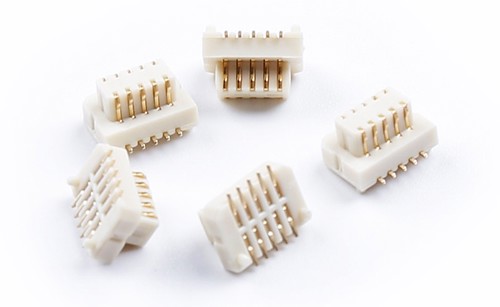

Rigid allows for interesting topologies and stacking options. It also allows for great customisation on plating depending on the requirement. Rigid may be ideal:

- To allow multiple PCBs to be produced in a single panel, reducing production costs.

- When PCBs are to be stacked, or mounted parallel or perpendicular

- When PCBs are to be pluggable/unpluggable

- For vertical and horizontal, male and female

- For a modular design approach (i.e. motherboard with multiple option daughter boards)

- Where you have lots of connection points in a condensed space

- When using SMD or through-hole components

- In low voltage and low current applications

Flexible allows greater distances and any angle between PCBs (rather than the conventional 90-degree increments). Flexible also allows multiple PCBs to be connected in a single panel. FFC (Flat Flexible Cable) is a cost-effective alternative to simple FPCs (Flexible Printed Circuits). Flexible may be ideal:

- To manufacture PCBs in-panel, snapped out and folded into position

- When PCBs are to be fixed or pluggable

- To position PCBs at angles from zero - 360 degrees

- Where distances between PCBs are significant

- In high vibration applications (where flexible cables act as a vibration damper)

- When using SMD, through hole or pin-in-paste components

For low voltage, low current to high voltage (large pitch), to high current (up to 12 amps) per connection point

To find exactly the right connector for your application, talk to us.