Today’s products must overcome performance in rugged environments, so vibration and acceleration simulation must be included in the product development process. Adding virtual vibration and acceleration simulation during layout will achieve: reduced design iterations and time-to-market; a less expensive product; the ability to simulate all designs vs. just high-risk designs; and increased reliability and prevent potential failures. By running virtual simulation on every board during layout, engineers and designers can detect issues early in the product development process to ensure design quality, decrease time-to-market and mitigate product risks.

To address this issue, Mentor has developed the industry’s first PCB design-specific vibration and acceleration simulation tool to remove the cost and time barriers for electronic systems designs that must perform under harsh environments. This new vibration simulation methodology for PCB design reliability and failure prediction augments mechanical analysis and physical testing with virtual accelerated lifecycle testing much earlier in the design process. It increases test coverage and shortened design cycles to ensure product reliability for military, aerospace, automotive and industrial markets.

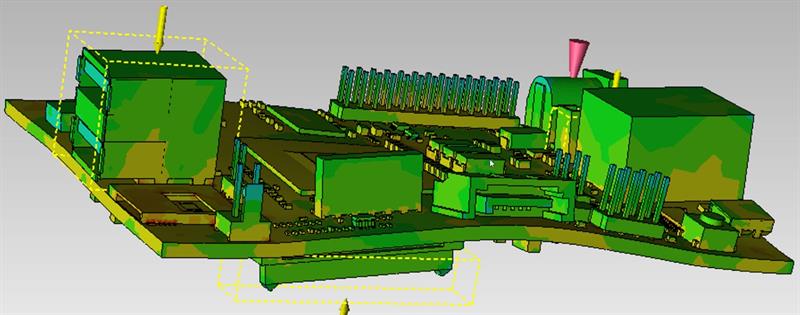

| Simulation results should be available in a two-phase post-processor for each simulation, providing broad input on the PCB’s behaviour under the defined conditions |

Its easy-to-use, automated design environment leverages a finite-elements engine for quick, accurate analyses. Unlike other tools, Xpedition is optimised for the PCB layout designer, enabling desktop simulation and redesign. With the industry’s most extensive component modelling library (over 4,000 unique 3D solid models), it creates highly defined parts for simulation. The ultra-fast system modelling tool creates over 1,000 components per minute, and users can assemble the parts models on board and automatically mesh them for performance analysis, including stiffeners and mechanical parts. The simulation Wizard provides fast and accurate virtual prototyping so users can see high-failure-probability components and analyse boundary conditions, material properties, and environment profiles.

| Mentor, a Siemens Business, is a technology leader in electronic design automation (EDA), provides software and hardware design solutions that enable companies to develop better electronic and mechanical products faster and more cost-effectively. The company offers innovative products and solutions that help engineers overcome the design challenges they face in the increasingly complex worlds of board and chip design. Mentor, a Siemens Business has the broadest industry portfolio of best-in-class products and is the only EDA company with an embedded software solution. Services Design-Through-Manufacturing PCB Systems Development Mechanical Analysis Functional Verification Design to Silicon New and Emerging Products Electrical System and Harness Engineering Electronic System Level (ESL) Design Embedded Systems Design Contact details Mentor, a Siemens Business |