The use of fans to cool electronic equipment has become increasingly widespread due to ongoing demands for miniaturisation. Convection cooling is ideal but usually increases the size of the product, and because air still needs to circulate around the product, there are restrictions. For example, additional derating is needed, and thermal hotspots can occur, leading to a reduction in component life, particularly with electrolytic capacitors. When convection cooled power supplies are used within a rack, there is often insufficient naturally circulated cooling air (a good rule of thumb is to allow 50mm space around the product to allow the hot air to rise and the cooler air to come in from the sides).

The choice of fan depends on a number of factors. Datacentres, for example, do not normally have continuous human presence, and equipment size and density takes priority. Plug-in redundant power supplies are typically 1U in height (44.4mm). Being rated at 2500 to 3500W, they have to dissipate more than 100W even when high efficiency products are used. Here, two high speed 40mm fans are often used. These fans exhibit audible noise which is not a problem in an uninhabited location, but even when a small telecom system is installed in an office, to handle a phone service, for example, the equipment has to be located in a separate room, away from human occupants.

Where human interaction with a machine or piece of test equipment is necessary, manufacturers are becoming increasingly concerned about audible noise. Engineers working in a laboratory using an oscilloscope need to be able to concentrate; technicians operating analysers to process fluid or chemical samples do not want to be subjected to persistent irritating and distracting audible noise.Medical equipment in the proximity of the patient has to be quiet to avoid complicating or delaying recovery.

Fan size, construction and speed all affect the amount of noise produced. Smaller fans have to spin faster to generate the same airflow and so are noisier. The comparison between a 40mm and 60mm fan in Table 1 demonstrates how the effective area is reduced due to the fan hub. Only one third of the cross sectional area is available for air to pass through for a 40mm fan, whereas almost half of the area is possible for a 60mm fan.

| Fan case size | 40mm | 60mm |

| Hub diameter | 24.4mm | 30mm |

| Blade diameter | 36mm | 56mm |

| Fan area | 1600mm2 | 3600mm2 |

| Available air passage | 550mm2 | 1756mm2 |

| Area blocked (no airflow) | 66% | 51% |

Table 1: Comparison of usable area for differently sized cooling fans

The choice of fan bearing also affects fan noise. A sleeve type bearing is quieter, but has a shorter lifetime than those using ball bearings. Mechanical noise produced by the bearings can cause vibration, and if the frequency of that vibration matches any resonant frequencies of the enclosure, it can be amplified to an intolerable level. Most manufacturers tend to only use ball bearing fans in order to enhance field reliability, the ability to endure high levels of heat and to counter variations in mounting orientation.

The stream of air from the fan blades causes turbulence in the airflow and contributes to the acoustic noise level. Ideally, there should be no obstructions in the airflow path, but internal to the power supply are heatsinks and electronic components, and airflow is required for cooling purposes.Sharp edges and bends on brackets and heatsinks should be avoided wherever possible, especially those in the immediate vicinity of the fan. Turbulent air in contact with a physical body will generate noise, often in the form of a discrete tone, raising the noise level as much as 10dBA, causing considerable irritation. To put this into context, a 10dBA increase equates to a doubling of the perceived loudness.

The use of variable speed fans is gaining in popularity. Here, a thermal sensor is either mounted in the airflow, or attached to a hot component. As the power supply gets hotter, due to changes in ambient temperature or output loading, the fan will speed up accordingly, until the desired temperature is achieved. The hysteresis of the fan control circuit is also important, as continually changing fan noise can become equally annoying. TDK-Lambda’s QM modular power supplies actually sense the incoming air temperature. This keeps the fan speed relatively constant, allowing quiet operation in a human environment, yet still provides sufficient airflow in applications requiring higher ambient temperatures.

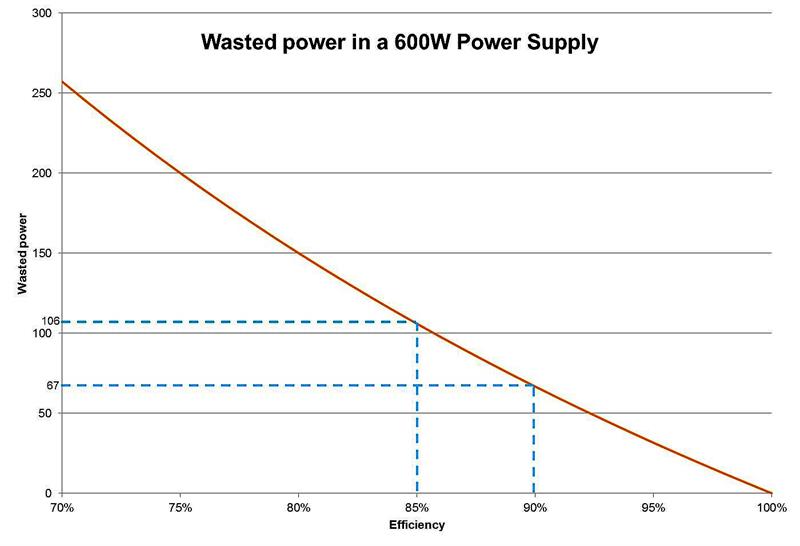

The efficiency of the power supply has a big impact in the amount of waste heat that has to be removed. Figure 2 shows how a 600W output power supply with an efficiency of 90% will generate 67W of waste heat, compared to 106W for an 85% efficient product.

Figure 2: Power supply efficiency versus wasted power

Figure 2: Power supply efficiency versus wasted power

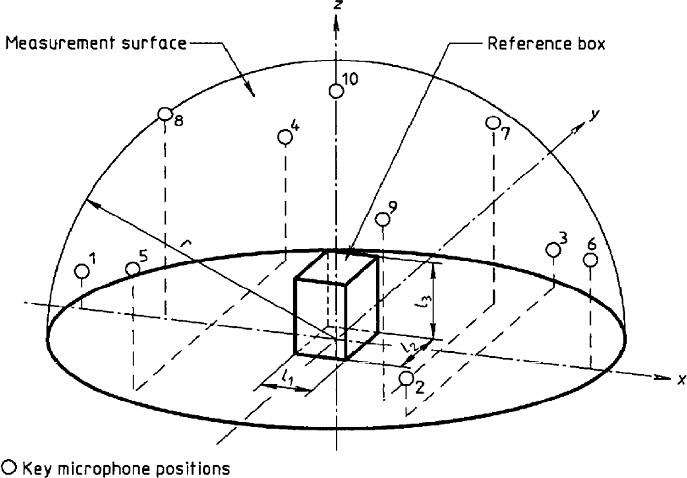

Less waste heat allows the use of slower speed fans, reducing the amount of acoustic noise generated. For higher output power supplies, 1000W and above, audible noise can be reduced further with the use of two fans, again running at slower speeds. TDK-Lambda’s 91% efficient QM7 series of 1200 to 1500W modular power supplies has two low speed, 60mm fans. The design engineering team performed extensive acoustic noise studies on similar products currently available on the market, plus the new QM unit. Tests were undertaken according to the BS EN ISO 3744:2010 standard.

|  |

Figures 3 and 4: Extensive acoustic noise measurement of the QM power supply

Results were impressive, with the 1500W rated QM7 measuring as low as 44.3dBA, compared to competitive products with levels as high as 58dBA. Note again, a 10dBA increase equates to doubling of the perceived loudness.

One further ‘blind’ acoustic noise study was made. For this, a range of 21 volunteers of differing ages were asked to rate the products on the relative loudness of each and assign an ‘annoyance factor’. The results for perceived volume and annoyance level correlated closely with the results from the first test. The QM7 again was voted both the quietest and the least annoying.

The QM series is the latest in a four-decade legacy of modular power supplies, beginning with the invention of the ML series, a world first, in 1979. The key criterion of minimising audible noise was selected over product height following extensive Voice of the Customer research initiatives. Using its considerable experience and extensive R&D expertise, TDK-Lambda has been able to make incremental improvements across the range of areas discussed in this article to optimise cooling fan performance in order to achieve this goal.

Having both medical and industrial safety certifications, the QM is suitable for a range of applications, including body floating rated medical equipment, test and measurement, broadcast, communications and renewable energy applications. The QM7 can deliver up to 1500W output power and up to 16 outputs can be provided, with voltages ranging from 2.8 to 52.8V. Module power ratings start with a low power 120W, with single or dual outputs, all the way to a powerful 1200W single output.

For more information about the QM series of modular power supplies, please visit: www.uk.tdk-lambda.com/qm

Author profile

Paul Goodwin is product manager at TDK-Lambda.