Model predictive control (MPC) is an advanced method of process control that makes use of a model of the system to predict its behaviour. The control law is based on an optimisation technique that computes the system inputs, taking into account the reference that the system output has to follow, together with the effort (energy) that is applied on the system inputs and some constraints that may exist within the system, typically saturation of the system inputs.

MPC also allows electronics equipment to perform at levels that are not possible with standard control laws, e.g. proportional-integral-derivative (PID) controllers. But this sophisticated technique is rarely used on low-cost, low-capability computing units, because it requires solving optimisation problems under constraints, which is a complex computational task.

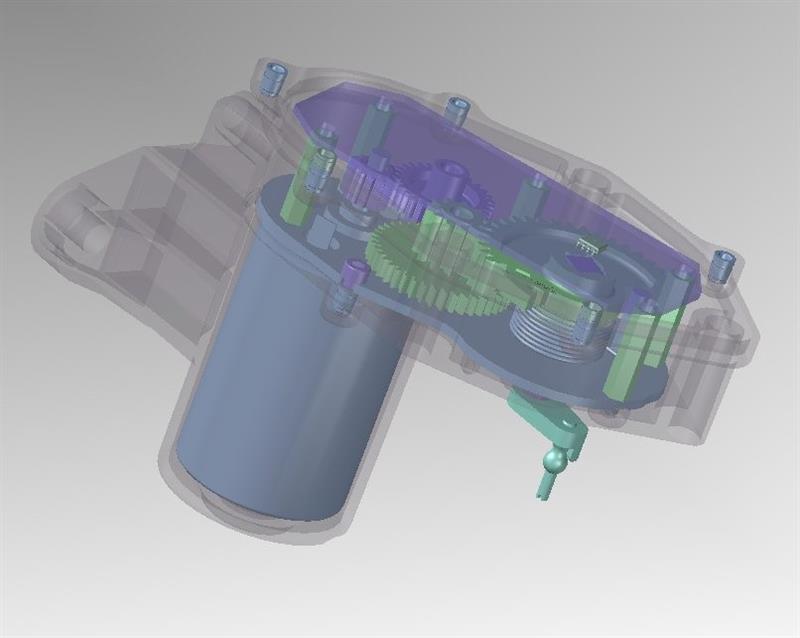

Leti and EFI Automotive are evaluating the implementation of MPC on low-cost, low-computational-capability computing platforms, such as microcontrollers (MCUs) or low-cost digital signal processors (DSPs). The goal is to improve the dynamics of the systems considered, because automotive certification is easier when the control law is implemented on a DSP or a MCU. An example of EFI Automotive product, which will benefit from the MPC implementation, is the Air Loop Actuator (Figure 1).

“The control community, including academic researchers and process control experts in industry, is trying to make MPC available for these systems by resolving the underlying optimisation problem on a low computational-capability computing platform,” said Marie-Sophie Masselot, business development manager, Leti. “This shortcoming usually leads to suboptimal performance for the controlled system. Our project with EFI Automotive will take into account specifics to offset the drop in performance, or response time, introduced when solving the model predictive control problem on this low computational-capability computing platform.”

Leti will also develop software-automation tools dedicated to a given problem as a feasibility demonstration for the MPC project, and then make the tools easily expandable to similar control challenges.For example, Leti and EFI will create an MPC law for a given system and, with its increased expertise, EFI will expand this control technique to other systems.

| Figure 1: EFI Air Loop Actuator Prototype (200ms response time). Numerical command and power stage integrated |