Jia Wei, Intersil’s director of marketing and applications engineering for mobile power products, noted: “The specification has evolved over time and is now at v3.1. Version 2.0 had limited data rate and power delivery abilities, so industry decided to work on something better. That was USB 3.0, which supported higher data rates and more power.”

In its original format, USB could transer 5W. “That’s not a lot,” said Wei. “It’s probably good enough for phone charging, but not fast.” But a new version of the standard called USB-C is set to change that, establishing a USB connector ecosystem that addresses the needs of the latest devices while retaining USB’s functional benefits.

“This will handle up to 20V, negotiable between both ends of the cable,” Wei pointed out. “Users can pass up to 3A over a passive cable,” he continued, “but need a special cable after that to handle up to 5A. Because the specification supports power levels of up to 100W, it’s good for a wide range of consumer electronic devices and other applications.”

“However,” Wei continued, “USB-C charging requires a fundamental change to the existing power delivery architecture and this presents a new challenge to system designers.”

In Wei’s opinion, the problems start when designers have a system in which a variable voltage passes over a USB cable. “These systems have to support 5V in order to be backwards compatible,” he said, “but they also need to handle up to 20V in order to support the latest devices.”

When a fixed input is greater than the output, designers can use a buck converter for all applications. “However, with a variable input,” Wei continued, “this relationship is uncertain and requires the use of a buck-boost converter, which also means there will be different modes of operation.”

He gave an example. “A challenge is how to use the 5V to 20V adaptor voltage to charge a 2.5V to 17.2V battery. There is no definite ‘input to output’ relationship, which would need the buck topology, and no definite ‘output to input’ relationship, which would need the boost topology.”

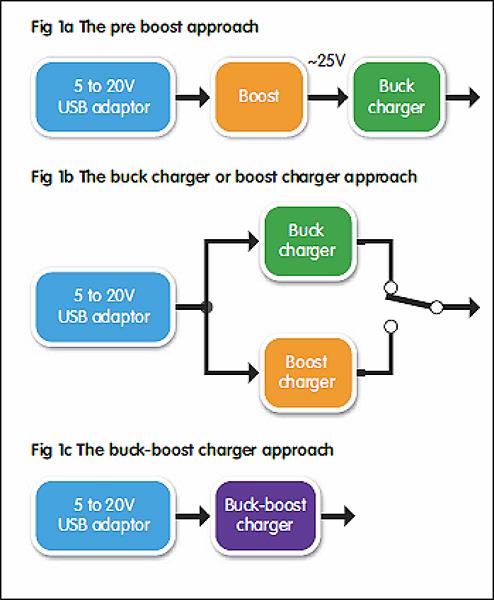

Figure 1a shows an approach based on the pre-boost concept. Here, the USB adaptor voltage is boosted to a voltage higher than the highest USB adaptor voltage – 25V for example – then down converted using a buck converter to charge the batteries. “This requires an additional boost converter,” Wei noted. “This increases solution cost and size, as well as reducing the overall efficiency due to power loss in the pre-boost stage.”

Figure 1a shows an approach based on the pre-boost concept. Here, the USB adaptor voltage is boosted to a voltage higher than the highest USB adaptor voltage – 25V for example – then down converted using a buck converter to charge the batteries. “This requires an additional boost converter,” Wei noted. “This increases solution cost and size, as well as reducing the overall efficiency due to power loss in the pre-boost stage.”

Another way of addressing the problem is shown in figure 1b. In the buck charger or boost charger approach, the USB adaptor voltage is handled by either a buck or a boost charger, depending on the input/output voltage relationship. While this configuration eliminates the additional power lossof the pre-boost design, it still requires an additional boost charger, meaning a larger, more expensive solution.

A more elegant arrangement, according to Wei, is the buck-boost charger shown in figure 1c. This can operate in buck mode when there is ‘input to output’, in boost mode when there is ‘output to input and in buck-boost mode when there is two way flow and the input is approximately equal to the output. “This,” said Wei, “allows for a better design, the smallest solution size and the best overall efficiency. It meets all the system designer’s requirements.”

Intersil says it is the only company currently producing a USB-C buck-boost charging product – the ISL9237. “When the market began to change,” Wei said, “we saw the need for such a device and entered the general market in 2016. However, we had developed a custom device for a particular client before that.”

The part consists of four switching FETs and an inductor, as well as a battery connecting FET (BFET), see fig 2. The four switching FETs are grouped into a forward-buck leg and a forward-boost leg. By operating either leg, this topology can operate in forward buck mode or forward boost mode for charging the battery. It can also operate in reverse buck mode to deliver power from the USB port in order to charge an external electronic device, such as a tablet, smartphone or the emerging portable power bank products that can be used to charge other products.

The ISL9237 offers a range of features, including the ability to communicate with an SMBus host. Compliant with USB 3.1, as well as the latest Intel IMVP8 PROCHOT# and PSYS requirements, it protects against battery voltage drop, adapter overcurrent, battery overcurrent and overheating. According to Intersil, the part provides a two level adaptor current limit with programmable magnitudes and durations.

Why USB-C?

“When I visit customers,” Wei explained, “they realise that USB-A and -B will be made obsolete by USB-C. Everything is changing and now it’s one cable for everything, including data and power.”

He also noted that USB-C has a particularly popular form factor. “That’s also appealing and it can be designed into very small devices. Once people see the benefits, many of them adopt the technology.”

But what about those designing products for markets beyond consumer electronics? “Those designing for the industrial equipment market, for example, will be starting to think about how they can tap into the USB-C ecosystem,” Wei contended. “We’re seeing a lot of industrial style applications turning to USB-C, looking to access such features as power management.”

But even though USB-C brings benefits – at least in Wei’s opinion – there is a downside. “Cost will be higher,” he admitted. “The connector is more expensive than devices used in the past, but cost will come down as USB-C becomes more of a mainstream technology.”

Another issue which designers need to take into account is the fact that USB-C involves power negotiation. This is handled by USB-PD (for power delivery), which is a piece of silicon sitting in each connector or port.

Negotiation sets the voltage level. “For example,” Wei said, “a designer might decide to save some cost by limiting operation to 12V, but that will also limit how much power can be delivered. System designers need to understand how to support the power levels and to choose cables appropriately.”

“Even without -PD,” Wei said, “devices will still be capable of power delivery, but it might be fixed at 5V. As the market evolves, we may see more ‘stripped down’ parts appearing. It comes down to market sentiment,” he added, “but it will be segmented.”

While USB-C is gaining momentum, other approaches are available. “Apple Lightning is similar, but it’s a closed ecosystem,” Wei explained. “Another technology is Qualcomm’s Quick Charge, which is trying to increase the amount of power delivered over a USB link. That spec is at v3.0,” Wei said, “and uses a different way of negotiating power without something like USB-PD.

“I think USB-C will win,” Wei concluded, “but it’s like the early days of Blu-Ray versus DVD; you have to choose.”