Do we need to fix it?

The transition from old motor control designs to this new era of processor controlled motors brings with it a range of benefits. Handheld tools, such as power drills, can be smaller and deliver higher torque, fridges can have higher energy efficiency and industrial machine movements can be more precise and detect abnormal forces to ensure operator safety.

Meanwhile, high performance motor control software enables fine control of rotor spin. Current to the motor is controlled by software, ensuring that only the necessary amount of electricity is used. This makes the motors more energy efficient than was possible with previous control technologies.

Advances in mixed signal CMOS integrated circuits have also allowed full featured single-chip motor control solutions, which reduce overall system component count and thus relieve product designers from traditional form factor constraints.

Transition headwinds

The transition from older electric motor technologies – such as brushed DC and inductive AC motors – to BLDMs and PMSMs has faced headwinds. Despite being less energy efficient and having lower performance, older motor technologies comprise the majority of spinning motors today for a number of reasons. As well as the natural inertia of equipment manufacturers adopting new technology, older electric motors enjoy well amortised manufacturing costs. On top of this, the introduction of new technology – and in particular technology demanding embedded software – demands significant expenditure on research and development. For industries where profit margins on the end product are traditionally low, this can be difficult to justify.

Impetus for Change

One of the biggest forces driving change is the energy efficiency demands on suppliers of high-voltage electric motor equipment. Typical motor efficiency – measured as a ratio between output mechanical power over input electrical power – ranges from 70 to 95%, with newer generation motors at the higher end. Improving efficiency by 10% can lead to annual savings of more than $1000 for a 20HP motor running continuously (assuming 15kW per hour consumption at a cost of .1/kWh).

Due to the sheer number of motors deployed across the world, OEMs are increasingly asking their motor suppliers for more energy-efficient designs, and this is driving the transition towards new motor control technology. In recognising this need for energy savings, government agencies have started to mandate energy saving targets for electric motors, especially those with higher power ratings.

For instance, Europe's Energy Using Products (EUP) Directive (EC640/2009) mandates strict requirements for energy efficiencies in motors, with compliance enforcement by 2017. As more energy efficient products become available, consumer demand puts further pressure on equipment manufacturers to accelerate their adoption of new motor control technology.

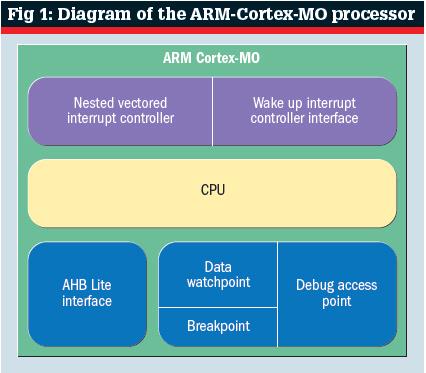

Designers of new generation motors face a number of problems, including form factor constraints, real time processor requirements and restrictions enforced by the Bill of Materials (BoM) cost envelope. With a powerful 32bit Cortex-M0 processor (see fig 1) at the centre of a full featured mixed signal integrated motor controller, these design problems can be eliminated, allowing designers to focus their efforts on other differentiating factors.

With only 12k gates in its minimal configuration, the Cortex-M0 processor combines a range of benefits, including ultra low power performance and low silicon footprint. The processor core includes hardware enabling single-cycle multiply operation and an easy programming model. In addition, the Cortex-M0's Nested Vectored Interrupt Controller enables very short and deterministic interrupt response times, whilst also supporting interrupt preemption, late detection of high priority interrupts, and interrupt chaining – all schemes that reduce overall power consumption during interrupt handling.

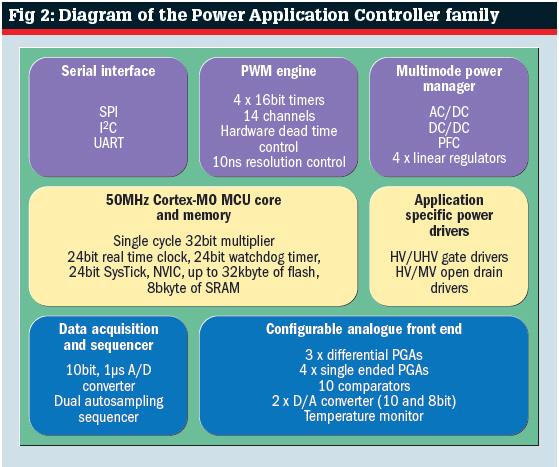

Active-Semi is a Dallas based manufacturer, offering single IC solutions for various power applications through its Power Application Controller (PAC) product family. These products integrate all essential analogue and power management peripherals, along with a 32bit ARM Cortex-M0 microcontroller core (see fig 2). The PAC IC solves many of the design challenges faced by new generation motor designers, in addition to offering a single integrated circuit solution for running motor control algorithms.

The Cortex-M0 core on the PAC IC is augmented by multi mode power management (MMPM), a configurable analogue front end (CAFE), data converters, autosampling sequencers and a 100MHz PWM engine. The MMPM enables PAC ICs to manage both AC input power (in an AC/DC flyback configuration) or DC input up to 72V (in buck or boost modes), thereby reducing the need for additional external mode switching components. In addition, four on board low dropout regulators (LDO) inside the MMPM offer system power rails, which eliminate the need for an external system power manager.

Reliability and safety are two other important aspects in motor control design. Automatic software fault detection on the Cortex-M0 enables a number of error conditions to be detected and handled, adding to system reliability. On safety, the CAFE block enables programmable gain amplifiers (PGAs) to detect system faults, which could be caused by abnormal current condition through a motor phase. The CAFE block would respond by shutting down high-voltage gate drivers, interrupting the Cortex-M0 processor and enabling further software action to be taken.

The future

Having this level of processing power inside a single integrated circuit promises to enable higher performance motor designs that are quieter, more precise and more energy efficient.

The programmable 32bit processor also opens up new product form factors that were, until now, impractical due to the need for sensors required by traditional DC brushed motors.

FOC algorithms running on the Cortex-M0 estimate motor position based on electro-magnetic field waveforms, doing away with the need for external motor position sensors altogether. Applications that require the use of FOC are likely to find that features in a PAC IC family offer the right balance between cost and programmability.

Whilst the user benefits offered by the inclusion of newer, more efficient software controlled techniques inside single IC motor controllers are compelling enough, compliance to government mandates for higher energy efficiency will be a key factor in driving this transition. As consumers become more accustomed to higher performing, more energy efficient and safer home tool and equipment, further demand will accelerate the transition of older to newer motor controllers by electric motor manufacturers.

Author profiles

Suribhotla Rajasekhar is director of marketing with Active-Semi International. Tim Menasveta is CPU product manager with ARM.