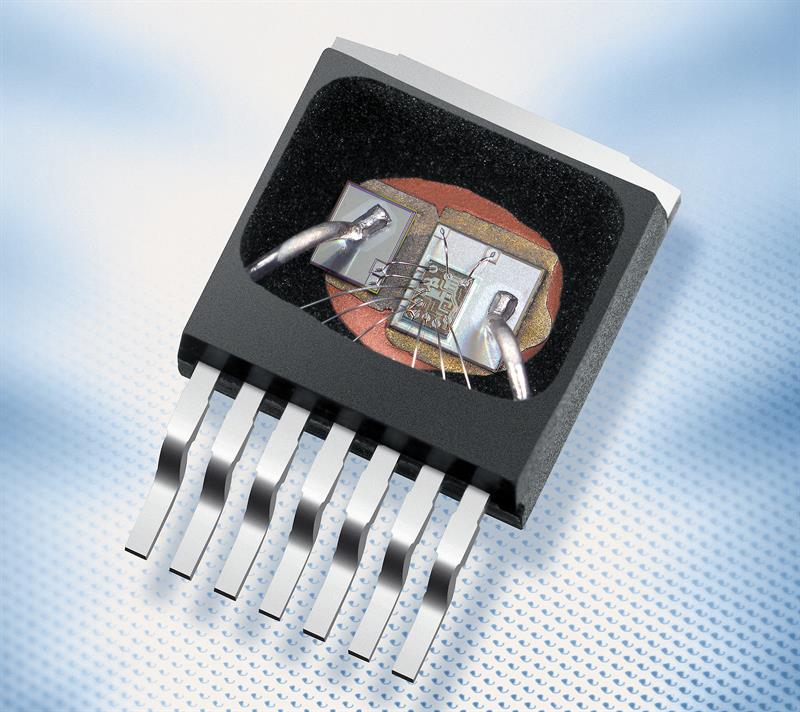

The high-current P/N-channel half-bridge BTN8962 and BTN8982 are suitable for automotive, industrial, robotic, home and medical applications, with voltages of up to 40V. Compared to the initial BTN79xx series, Infineon has significantly improved a whole range of technical features, with the switching time being almost halved and the RDSon in the high side (HS) and low side (LS) buses having been optimised by 50%. Furthermore, the current limiter is 22% better in the HS bus and 50% better in the LS bus than the predecessor series. As a result, these modules ensure the benefits of a compact design with integrated drivers are available to applications exceeding 250W, without the need for additional cooling. The high level of integration of the components encompasses overcurrent and overheat protection as well as an undervoltage cut-off mechanism. This means less design work and therefore lower system costs, which enables developers to optimise their applications. The D2PAK (TO263-7) housing and pin-out have remained the same, ensuring that the NovalithIC products are footprint and pin-compatible with the existing series.

Turning five into two – integrated components for space-critical applications

The internal three-chip structure encompasses a half-bridge driver, an n-channel and a p-channel MOSFET in a chip-by-chip and chip-on-chip design. This solution creates maximum performance with minimum space. This range differs from the BTN79xx series by using the most up-to-date MOSFET technology for n and p-channels.

In an ordinary H-bridge application for controlling a bi-directional brushed DC motor (BDC), this would enable five chips – the half-bridge driver and four MOSFETs – to be replaced by two NovalithICs, saving a significant amount of assembly work and space.

Minimal parasitic effects = minimum design effort

Parasitic leakage in the link is a key problem in controlling highly dynamic systems such as PWM-controlled DC brush motors. A critical point is the node between the high-side and low-side MOSFETS leading to the motor. Because wire lengths are not a concern in the NovalithIC range, the voltage peaks are five times less than in discrete solutions under comparable conditions. For developers, this means easier circuit design along with savings in the passive components or diodes needed in discrete circuit design to reduce the negative voltage peaks.

Everything on board – diagnostic tools, protective functions and control

The diagnostic functionality of the NovalithIC range enables current measurements. Without additional measures, this has a precision of more than ±28%. Simple end-of-line calibration enables precision to reach ±10%, and with additional measures such as temperature compensation, it can achieve ±3%.

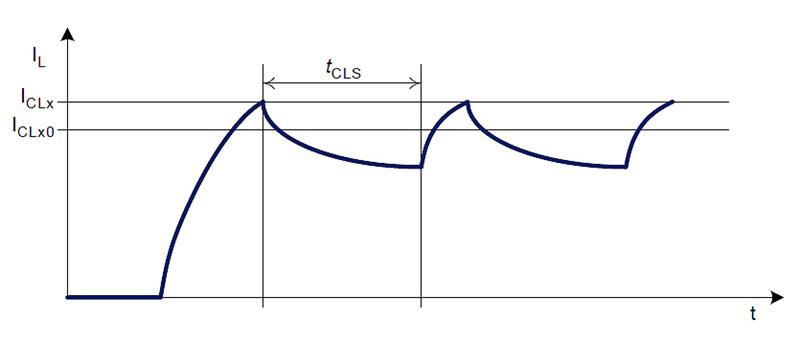

To detect overcurrent scenarios, the NovalithIC range uses a separate internal current measurement function that gauges the current flowing through the HS and in the LS switch. If an inductive load is triggered by the IC, this overcurrent detection function will limit the current by briefly shutting off the affected switch. The user receives a defined state at the IS status pin, and this can be read in the MCU, improving the circuit’s performance. In a motor, for example, shut-offs, which are caused by system factors, can generate a high amount of reverse leakage current. This can either be reduced by adding an additional circuit or designing the circuit to withstand high loads. Both methods, however, are complex and incur additional expense. The NovalithIC, on the other hand, limits the current to the pre-defined value and controls everything automatically.

Time diagram of current limiter (inductive load)

A temperature sensor is placed on the logic chip, directly on the p-channel MOSFET, to provide protection against overheating. While a discrete circuit with external MOSFETs could previously only roughly estimate the temperature, the integrated design of the NovalithIC allows measurements to be performed directly on the object.

The integrated undervoltage protection prevents the connected motor from moving uncontrollably. The NovalithIC is protected against short circuits by a combination of current limiter and overheating protection, providing security against short-to-ground or short-to-power, as well as shorting of the load.

The simple control mechanism is another of the NovalithIC's advantages. With a half-bridge design with external MOSFETs, the user has to ensure that there can be no short circuits, cross current or ‘shoot-through’ current when the MOSFETs are connected. With the NovalithIC, however, switching a logical pin for the driver circuit is all it takes to handle the switching of the MOSFETs.

Motor control with integrated functional security

All NovalithIC chips meet the AECQ-100 standard and operate in temperatures ranging up to 150°C, making them suitable for automotive applications, including motor designs with DC or brush motors (unidirectional and bidirectional), three-phase brushless motors, heating and air conditioning fans, sunroof controllers and electrically adjustable seats. Because the ICs can operate up to 40V, they can also be used in industrial applications such as white goods and tools.

The Infineon ICs also offers a benefit for safety-critical applications when, for example, two ICs are deployed in an H-bridge design for bidirectional control. Such designs automatically offer redundancy in the controller logic – as every NovalithIC has its own control chip, the developer can stop the motor using the other IC if one IC fails. With a discrete design, in which just one H-bridge driver controls the four MOSFETs, this would result in complete loss of control, unless measures are taken to prevent this.

Arduino shield for the mass market

Infineon sees great potential for the NovalithIC range in the mass market and catalogue distribution market. This is why the manufacturer has developed a DC motor control shield with two BTN8982s that is compatible with the Arduino. It is aimed at any control system for brush DC motors with a bidirectional or two unidirectional motors with up to 250W in motor output. The NovalithIC can drive up to 55A, but due to thermal restrictions resulting from the size of the shield and the layout, it is not recommended to use the shield for long-term operation at more than 250W. The design of the shield includes reverse polarity protection, implemented by a MOSFET positioned in the circuit.

Author profile:

Mathias Müller is global product sales manager, power management, and member of the automotive business unit at Rutronik.