With an ageing population and the growing cost of healthcare, access to this type of medical monitoring equipment, outside of a hospital, is now becoming more important.

Multiparameter monitors need to be accurate, small, and able to operate for a long period of time from a single battery charge.

Many such systems look to combine two or more measurements and each one is performed by a dedicated analogue front end, resulting in the need for several chips, each with its own analogue-to-digital converter (ADC), its own interface to the main processor, and several power supplies and reference voltages that need to be decoupled.

As a result, there are many redundant building blocks, which is certainly not ideal from a size and power perspective. In a wearable system, the aim is usually to have one main signal chain to which each sensor can be connected – but a new family of biomedical front ends is looking to address this.

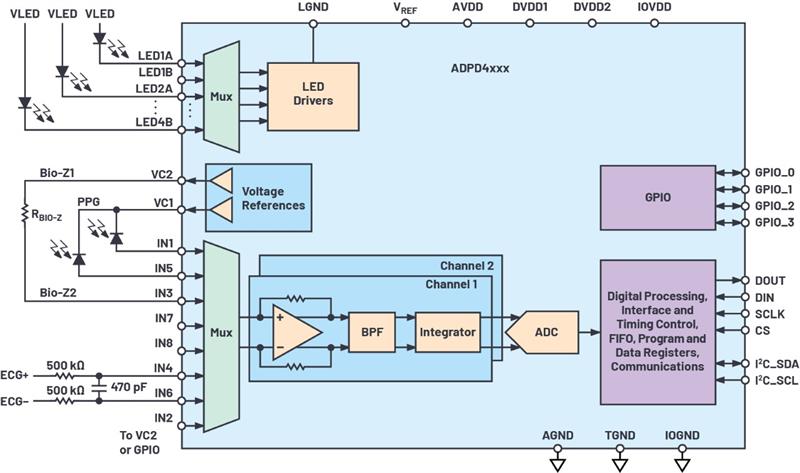

The ADPD4000 has been designed around two identical receive channels, which can be sampled simultaneously. Each is differentially built, which makes it possible to measure any sensor input in either a single-ended or differential measuring mode.

The input stage is a transimpedance amplifier, with programmable gain, followed by a band-pass filter and integrator, capable of integrating 7.5 pC per sample.

The ADC is a 14-bit successive approximation register (SAR) converter with a maximum sampling rate of 1 MSPS. In front of each of the signal chains is an 8-channel multiplexer that gives the front end flexibility in routing the various sensor signals into the AFE.

Figure 1: High level block diagram of the ADPD4000 famil

Various signals can be measured and it is possible to modify the AFE as an optical front end, for instance, to measure either optical heart rate or oxygen saturation. In this mode, the photocurrent is measured, so a high transimpedance input stage is needed to convert current into a voltage. Interference, coming from ambient light, also needs to be cancelled.

Next to a receive signal chain, the chip supports eight output drivers, which can be used to provide stimuli. Each can configure one or more outputs to drive LEDs for an optical measurement, or one or more driver outputs can be used as excitation for impedance measurement, either to measure skin impedance or electrode impedance - hich affects the measurement quality - while performing a biopotential measurement.

The chip has been designed to allow the user to pre-program each configuration or measurement in a certain time slot – up to 12 time slots are supported - which makes the system easy to use once it is configured. Additionally, the chip does not require additional processor resources, keeping the system’s overall power consumption at a minimum.

On the chip, oversampling improves the effective number of bits (ENOB) of the ADC. The decimated data path is 32 bits wide. Measurement results can be stored in a 256-byte or 512-byte deep FIFO (ADPD400x vs. ADPD410x).

There is an integrated time stamp function to support synchronisation among data samples, which is required once multiple sensor data are used to find correlation among the various measurement results.

Each time slot starts with a precondition pulse, followed by a stimulus pulse and, finally, the photodiode current or signal from another sensor signal that is sampled by the ADC.

After power up, followed by a reset operation, the chip enters sleep mode. After waking up the chip, it’s possible to sequentially sample two ECG signals, followed by an optical measurement to perform a SpO2 reading and an impedance measurement to measure skin conductance (EDA/stress).

ECG measurement made easy

An ECG is the measurement of an electric signal generated by the human heart, due to depolarization and repolarization of the heart muscle per every heartbeat.

The signal is typically 0.5 mV to 4 mV in amplitude and measured over a frequency range from 0.05 Hz up to 40 Hz. It can be performed to solely measure heart rate, but practitioners are more interested in the waveform itself, which can be used as a measure for cardiac performance or a pre-warning to a potential cardiac.

The cardiac activity is monitored by attaching electrodes to the skin and for good contact wet electrodes are typically used. The most popular are silver/silver-chloride (Ag/AgCl) electrodes.

In out-of-hospital applications, these electrodes are very uncomfortable and can easily dry out or start to irritate the skin. Furthermore, though dry electrodes are often used, the contact between skin and electrode is degraded leading to less accurate readings.

The ADPD4000 uses a voltage input, and the ECG circuit measures electrical charge accumulated on a sensing capacitor. With an optimised time-constant calculated from the passive RC network and sampling rate, the charging process eliminates the variation on the skin-to-electrode

contact impedance. This ECG circuit has inherent immunity to variations in the skin-to-electrode contact impedance.

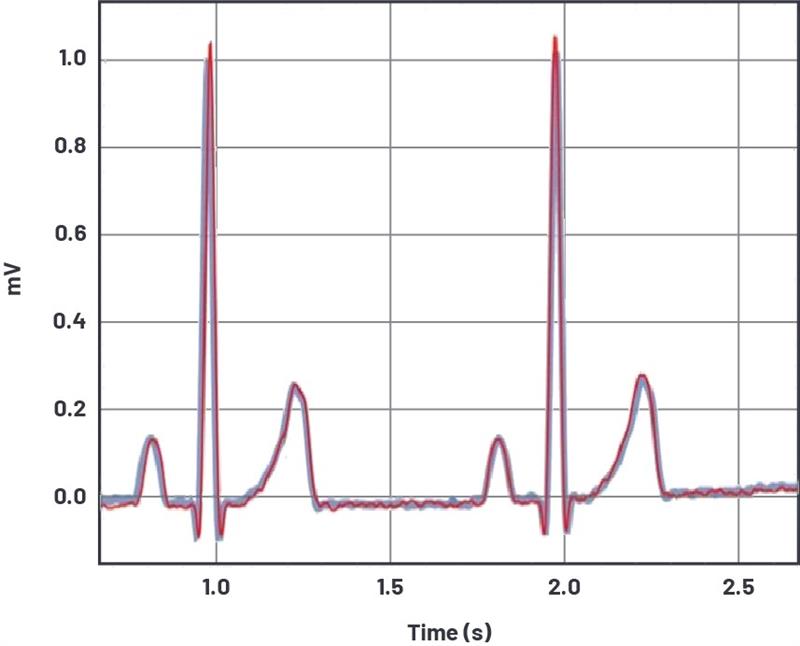

Figure 2: Two ECG waveforms measured with different electrodes

In Figure 2 two ECG waveforms are shown. The blue one has been measured with a good quality electrode, having a series impedance of 51 kΩ and 47 nF capacitance. The red waveform has been measured with a poor quality electrode and has a 510 kΩ contact impedance with 4.7 nF capacitance. It is possible to see that the ADPD4000 is measuring both waveforms, almost identically, independent of the electrode quality.

This is a huge advantage of this front end over other solutions currently on the market.

An additional advantage is that this circuit is extremely power efficient, it doesn’t have to be active while capturing the ECG signal on the charge capacitor. Another advantage is that it consumes 150 µW to 200 µW.

PPG and bioimpedance

For optical and bioimpedance measurements, LED drivers are required to emit light and to excite a current into the body, respectively. In many optical systems, more than just one wavelength is used, which makes the chip’s versatility very desirable.

The ADPD4000 has eight output drivers, where four channels can be used simultaneously with a programmable output current of maximum 200 mA per channel or 400 mA for the total driver section.

Depending on the configuration, it is possible to operate multiple time slots, each with its own wavelengths to measure optical heart rate, SpO2, hydration, or dehydration etc.

Each receive signal chain has a programmable transimpedance amplifier followed by a dual-stage rejection block to cancel out ambient light interferers. The signal-to-noise ratio (SNR) of the transmit/receive signal chain is up to 100 dB, which makes the device useful for noise-sensitive optical measurements such as oxygen saturation measurement or blood pressure estimation.

The power consumption of the optical system very much depends on the system configuration such as sampling and decimation rate, and the LED current used.

Many wearable systems measure skin conductance for applications like EDA, stress, or mental-state monitoring.

An excitation current is needed in order to measure a voltage drop. The ADPD4000 supports this and the chip can be configured in a 2- or 4-wire measuring mode. An enhanced waveform generator and DFT engine are not included, so in case impedance spectroscopy is required, the AD5940 should be used as a companion chip to complement the ADPD4000. The impedance function also can be used to measure electrode quality or for lead-off detection.

Almost ideal?

The ADPD4000/ADPD4001 looks to address the challenges designers face when working on wearable devices, body patches, or drug delivery systems, where performance, size, and power dissipation are critical specifications.

This biomedical front end provides high performance, dual-channel sensor input stage, stimuli channels, digital processing engine, and timing control, meets all these requirements.

While both the ADPD4000 and 4001 have reached volume production a next generation, ADPD4100/4101, is now expected to become available in the first half of 2020.

This new generation has improved signal-to-noise specifications and additional features that can help to further reduce the power consumption of the entire system.

Despite all these functions included in a single chip, however, it won’t make the electronic design engineer’s job redundant. There remain many parameters to configure to give each system its own identity.

Author details: Jan-Hein Broeders, Healthcare Business Development Manager, Analog Devices