Of all the relay types, EMRs are probably the best general purpose solution, meeting the needs of applications ranging from automotive to automated test equipment. Many different specialist types of EMRs exist for everything from signal transmission to power electronics applications. While EMRs are often specified purely for cost reasons, they do have some redeeming features.

EMRs are mechanical devices that physically open and close electrical contacts when they are switched on and off. This means they have a very low contact resistance – in the tens of milliohms – which is important for applications that require a minimal on state voltage drop. They also offer very high open resistance – typically more than than 100GO. Contact capacitance is also less than what’s offered by solid state relays, which means they can offer the linear response that is needed to minimise distortion of high frequency signals. Not only that, they have high bandwidth characteristics – sometimes in excess of 100MHz.

Line to load applications

Applications that require galvanic isolation between the drive electronics and the relay contacts will make use of the EMR’s ability to provide nearly total line to load isolation. Even multiple pole devices, which can control multiple circuits at the same time, are fully isolated.

EMR contacts are large and robust, so they can withstand power surges and voltage spikes. Whilst, under some circumstances, transients can switch solid state relays, this isn’t a problem for EMRs. Solid state relays also have a tendency to fail in short circuit mode, which can lead to damage for the equipment or circuits being switched on or off.

Of course, the use of EMRs does have its downsides. Audible noise is one, as well as limitations on switching speed (5 to 15ms) and their general bulkiness. Nevertheless, there are many application areas where these criteria are less important than cost, or the EMR’s other features such as surge resistance, so it’s a matter of matching the strengths of the relay type to the application’s requirements.

Life expectancy, in particular, is often thought of as relatively low for EMRs, but this is one property on which manufacturers have been working in recent years. Since they are mechanical components, they have a finite lifetime – referred to as endurance – which begins when the relay is first switched. Endurance is usually defined in terms of how many switching operations the relay can be expected to perform under certain conditions before failure.

TE Connectivity's relay 150 is intended for engine control, heated windscreens and other automotive applications

Endurance figures

EMR datasheets will typically give both the mechanical and electrical endurance figures. Mechanical endurance is a measure of the number of cycles of operation a relay can be expected to perform with no electrical load. The electrical endurance gives the expected number of cycles of operation before failure under a certain electrical load. Endurance is sometimes separated for AC and DC loads if the relay is suitable for use with both. Note that mechanical and electrical endurance have different failure criteria – that is, they are not comparable. Mechanical endurance is therefore not a good approximation for electrical endurance under low load conditions.

The typical conditions under which electrical endurance is measured include a relay duty factor of 50% at the rated frequency and voltage, with a resistive load, at ambient temperature (usually 23°C) with the relay upright and wired directly (not mounted on a socket) and with the contact opening/closing not synchronised to line frequency. Of course, if your application demands conditions different to these standard test conditions, some level of derating can be expected.

Here are some examples of modern EMRs and their failure rates. The Omron MY series includes a broad range of general purpose relays. The MY2 series of miniature power relays offers a minimum mechanical endurance of 50million operations when used with an AC load, or at least 100m operations when used with a DC load. Its electrical resistance is 500,000 operations minimum at rated load and its rated switching frequency is 18,000 operations per hour.

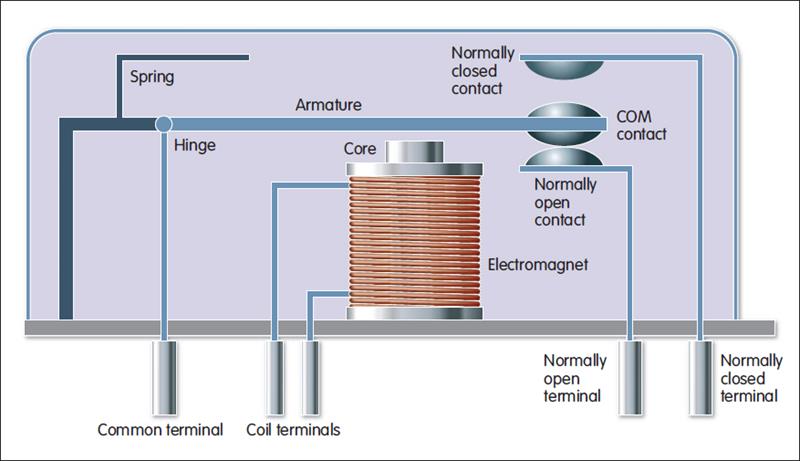

Cross section of a typical electromechanical relay

Cross section of a typical electromechanical relay

Relays for 2A signals

The GQ series of signal relays from Panasonic Electric Works is rated for 2A signals. The devices have a minimum expected mechanical endurance 50m operations when switched at 180 times per minute. Their electrical endurance with a 2A, 30Vdc resistive load is a minimum of 50,000 operations at 20 times per minute, but halving the current to 1A with the same voltage will extend the endurance to a minimum of 100,000 operations at 20 times per minute. For 0.3A, 125Vac resistive loads, a minimum of 100,000 operations at 20 times per minute can be expected.

TE Connectivity’s high current relay 150 is a much bigger device, intended for engine control, engine preheating systems, heated windscreens and other automotive applications. Its mechanical endurance is 10m operations minimum and its electrical endurance is 50,000 cycles minimum at 300A, 13.5Vdc.

Author profile:

Mathias Goebel is a product marketing manager with Avnet Abacus.